Continuous ultrasonic welding equipment for thermoplastic composite material and application of continuous ultrasonic welding equipment

A composite material, ultrasonic welding technology, applied in the field of thermoplastic resin matrix composite material manufacturing, can solve problems such as limiting the application of ultrasonic welding technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

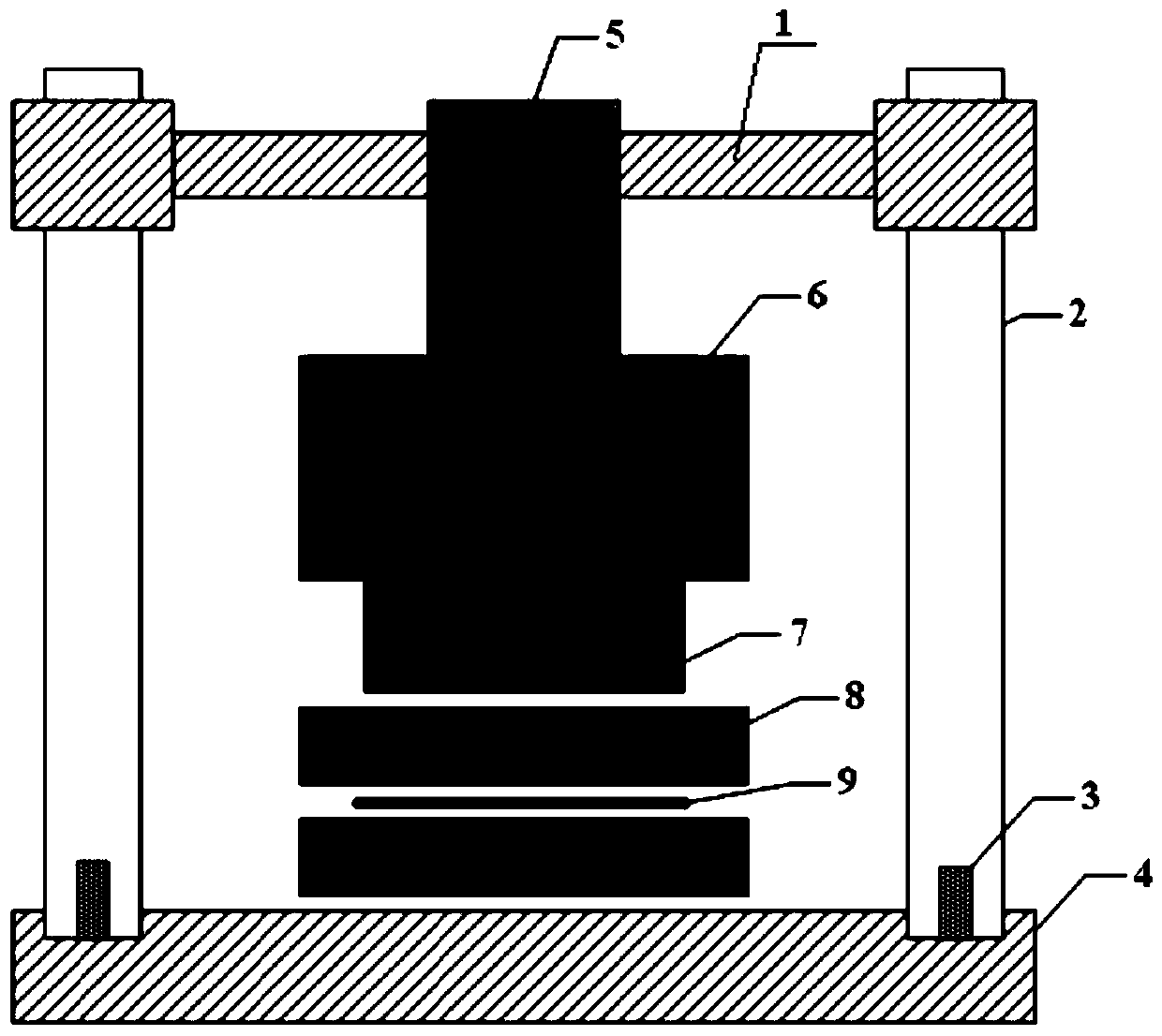

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Welding of carbon fiber reinforced polyetheretherketone resin-based composite (CF / PEEK) plates. A PEEK resin film with a thickness of 0.3mm is placed between the soldering surfaces as solder. Adjust the power of the first servo motor, set the welding pressure to (2.0±0.2)MPa; adjust the output power of the ultrasonic amplifier, and set the welding surface temperature to (420±10)°C. Adjust the moving rate of the moving column to (20±5) mm / s, and move at a constant speed along the welding seam track to complete the welding.

Embodiment 2

[0040] Example 2: Repair of carbon fiber reinforced polyphenylene sulfide resin matrix composite (CF / PPS) plate with delamination damage. Adjust the power of the first servo motor, set the welding pressure to (1.5±0.1) MPa; adjust the output power of the ultrasonic amplifier, and set the welding surface temperature to (350±10)°C. Adjust the moving rate of the moving column to (20±5)mm / s, sweep back and forth to cover all the delaminated areas, and complete the repair.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com