System and method for treating desulfurization wastewater by utilizing flue gas waste heat

A wastewater treatment system and desulfurization wastewater technology, which are applied in gaseous discharge wastewater treatment, water/sewage treatment, chemical instruments and methods, etc. Insufficient road space, low investment and operating costs, and reduced pretreatment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

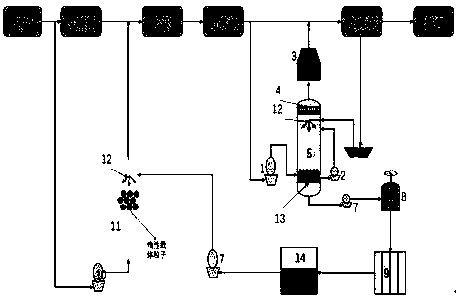

[0025] A system for treating desulfurization wastewater by using flue gas waste heat, the system includes a boiler, an air preheater, an electrostatic precipitator, an induced draft fan, a concentration system arranged in parallel, a desulfurization tower and a chimney connected in sequence through a flue; the bottom of the concentration system The liquid outlet is connected to the spray device 12 in the drying bed 11, the flue before the air preheater is connected to the inlet of the drying bed 11, and the outlet of the drying bed 11 is connected to the flue; The air inlet is connected with the flue between the induced draft fan and the desulfurization tower through the compressor. The compressor is a compressor with 100% capacity and is arranged in the open air. The compressor can increase the temperature of the flue gas and increase the evaporation effect of the waste water; in addition , It can also increase the kinetic energy of the flue gas and overcome the resistance of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com