Production method of annular ceramic product

A production method and ceramic technology, applied in the production field of annular ceramic products, can solve the problems of complicated use of molds, difficult filling and demolding, limited application scope, etc., so as to reduce processing volume, reduce production costs, and improve product qualification. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a method for producing an annular boron carbide ceramic product, the method comprising the following steps:

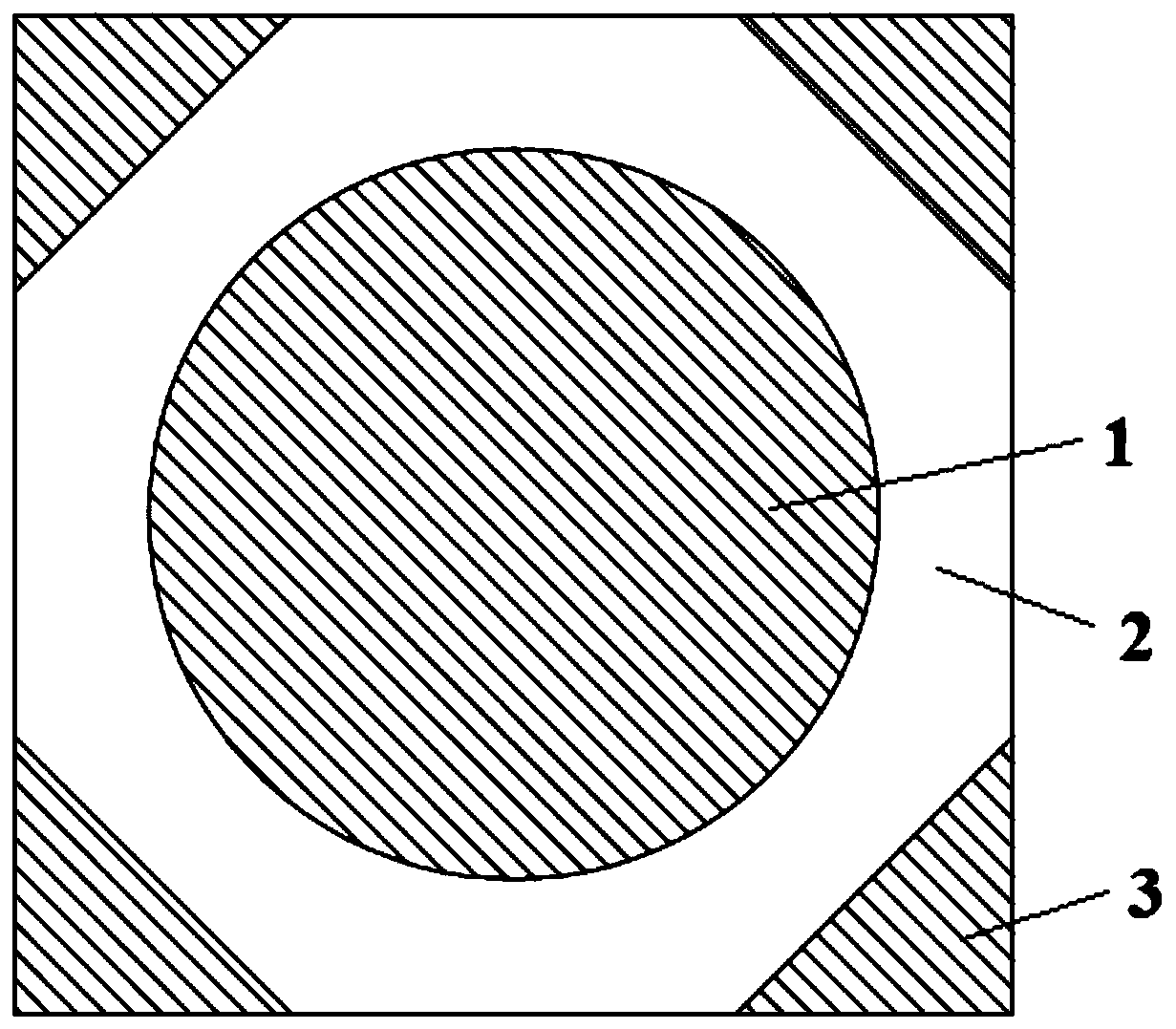

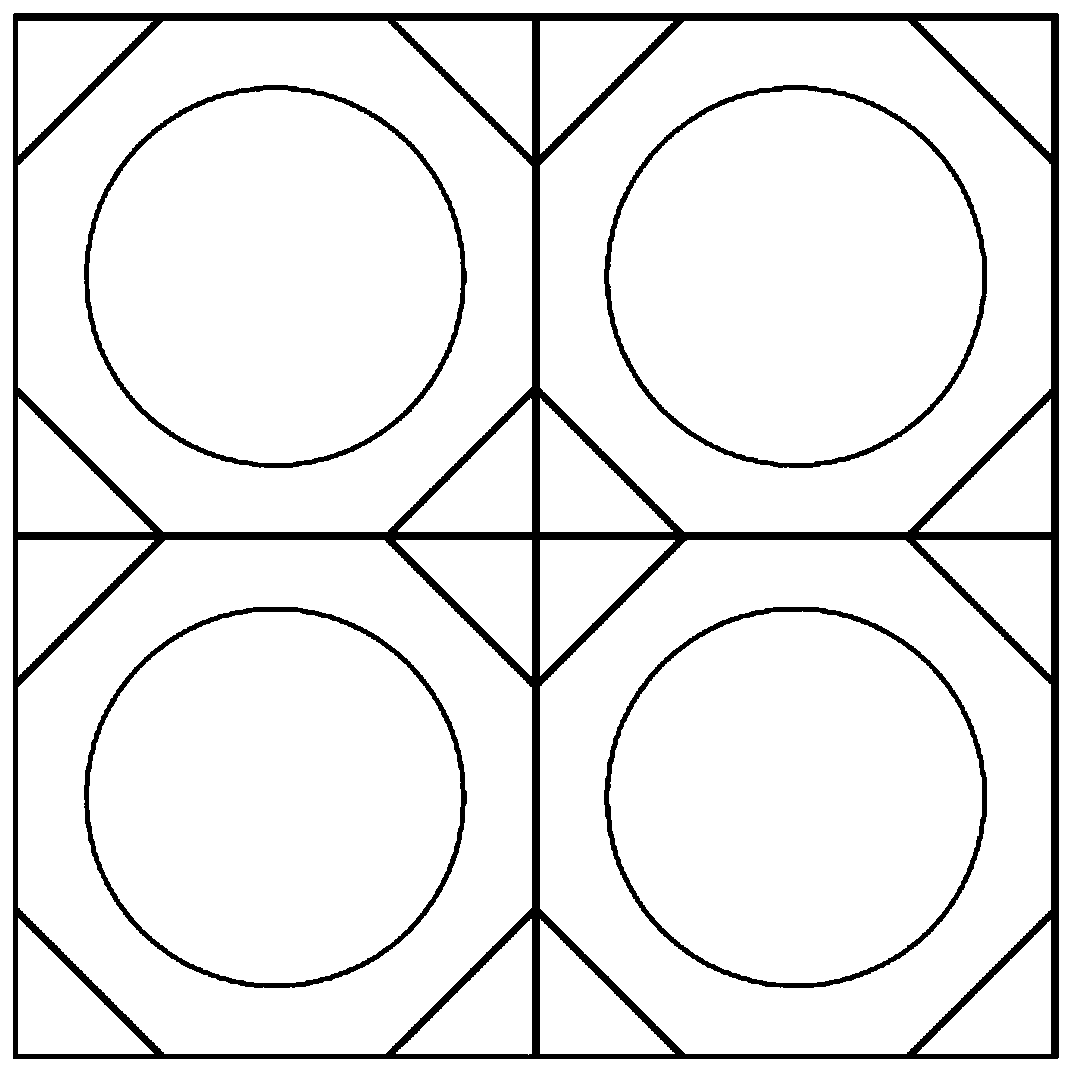

[0058] (1) After mixing boron carbide powder and binder, carry out cold press molding in a cold press mold, the mixing mass ratio of cellulose and water in the binder is 1:29, and the boron carbide powder and binder The mixing ratio of the agent mass is 93:7, the pressure of cold forming is 6MPa, and the temperature is 20°C to obtain a cold-pressed part that matches the size of the finished product. The cold-pressed mold divides the cold-pressed part into a circular central area 1 and Two parts of the edge area, and then the edge area is divided into four-corner area 3 and the remaining area 2 to be processed by wire cutting. figure 1 shown;

[0059] (2) Pack the cold-pressed parts that step (1) obtains into the graphite hot-pressing mould, five layers of cold-pressing parts are filled in the mold cavity of the hot-pressing mold, and fo...

Embodiment 2

[0062] This embodiment provides a method for producing an annular silicon carbide ceramic product, the method comprising the following steps:

[0063] (1) After mixing silicon carbide powder and binder, carry out cold press molding in a cold press mold, the mass ratio of polyvinyl alcohol and water in the binder is 1:10, and the silicon carbide powder and binder The mixing mass ratio is 9:1, the pressure of cold forming is 8MPa, and the temperature is 15°C to obtain a cold-pressed part that matches the size of the finished product. The cold-pressed mold divides the cold-pressed part into a circular central area 1, Three parts of the area to be processed 2 and the four-corner area 3;

[0064] (2) Pack the cold-pressed parts that step (1) obtains into graphite hot-pressed moulds, and fill three layers of cold-pressed parts in the mold cavity of the hot-pressed mold, and fill six cold-pressed parts in each layer, and between different layers of cold-pressed parts Graphite paper ...

Embodiment 3

[0067] This embodiment provides a method for producing an annular boron nitride ceramic product, the method comprising the following steps:

[0068] (1) After boron nitride powder and binder are mixed, cold press molding is carried out in a cold press mold, the mixing mass ratio of polyvinyl butyral and ethanol in the binder is 1:15, and the nitrogen The mixing mass ratio of boron powder and binder is 92:8, the pressure of cold forming is 4MPa, and the temperature is 30°C, so as to obtain cold pressed parts matching the size of the finished product, and divide the cold pressed parts by wire cutting It consists of three parts: the circular central area 1, the area to be processed 2 and the quadrangular area 3;

[0069] (2) Pack the cold-pressed parts that step (1) obtains into graphite hot-pressed moulds, fill six layers of cold-pressed parts in the mold cavity of the hot-pressed mold, and fill nine cold-pressed parts in each layer, and between different layers of cold-pressed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap