Continuous synthesis method of ethoxymethylene malononitrile

A technology of ethoxymethylene malononitrile and synthesis method, which is applied in chemical instruments and methods, preparation of carboxylic acid nitrile, preparation of organic compounds, etc., and can solve the problems of low yield, environmental safety of toxic solvent pollution, etc. , to achieve the effects of increased yield, reduced high-temperature dangerous area, and avoided decomposition of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

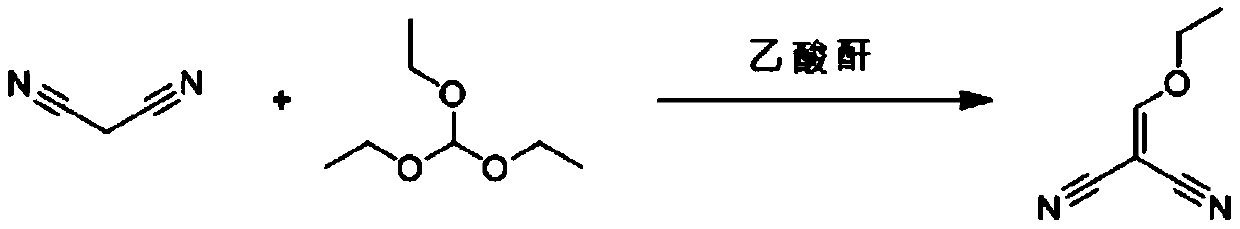

[0022] In order to solve the above problems, the invention provides a continuous synthesis method of ethoxymethylene malononitrile, which comprises the following steps: malononitrile, triethyl orthoformate and acetic anhydride are continuously passed into the continuous reaction equipment Carry out substitution reaction in, obtain ethoxymethylene malononitrile, and in the process of substitution reaction, the ethoxymethylene malononitrile of generation discharges continuously; Wherein, malononitrile, triethyl orthoformate The molar ratio with acetic anhydride is 1:(0.9~6.0):(2.0~6.0).

[0023] The invention realizes the continuous production of ethoxymethylene malononitrile through the continuous substitution reaction of malononitrile, triethyl orthoformate and acetic anhydride by adopting continuous reaction equipment. Compared with the traditional kettle reaction, since the amount of materials participating in the reaction per unit time is greatly reduced, the high temperatu...

Embodiment 1

[0035]

[0036] The feeding amount is 1.0kg, under room temperature, malononitrile (1.0kg, 15.14mol) and acetic anhydride (3.25kg, 31.79mol) are mixed uniformly, and it is recorded as material A; triethyl orthoformate (2.47kg, 16.65mol) is recorded as for material B. Pump A speed is: 248g / min, pump B speed is: 157g / min, material A and material B are pumped in the continuous pipeline reactor (volume is 50L) with pump respectively, temperature control 120 ℃, continuous reactor outlet is prepared The pressure is 0.3~0.5MPa, the residence time is 100min, and the outlet sample is analyzed by GC, and the remaining raw material is 0.0~0.5%. Concentrate the system flowing out of the continuous reactor to 6V under vacuum, control the temperature at 20-30°C, and add 4V n-heptane dropwise to the above system. After the dropping is complete, a large amount of solids are precipitated out of the system. Filtration and drying of the solids gave 1.83 kg of the product ethoxymethylenemalon...

Embodiment 2

[0038] Pump A system is malononitrile (100g, 1.51mol) + acetic anhydride (325g, 3.18mol), pump B is triethyl orthoformate (247g, 1.67mol), pump A speed is: 24.8g / min, pump B The speed is: 15.7g / min. Simultaneously turn on pump A and pump B to pump two streams of raw materials into the continuous reactor (volume 5L), control the temperature at 130°C, prepare the pressure at the outlet of the continuous reactor at 0.3-0.5MPa, and keep the residence time at 100min. Take samples from the outlet for GC analysis. The remaining raw material is 0.0-0.5%. The outflowing system is concentrated, concentrated to 6V, added dropwise with 4V n-heptane for crystallization, and filtered to obtain 165.0g of the product ethoxymethylenemalononitrile, GC purity: 97.2%, Yield 79.8%.

[0039] The difference from Example 1: the reaction temperature is 130°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com