Amphoteric glucan hydrogel and application thereof

A dextran and hydrogel technology, applied in the polymer field, can solve problems such as unreported, and achieve the effects of reducing inflammatory response, good biocompatibility, and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

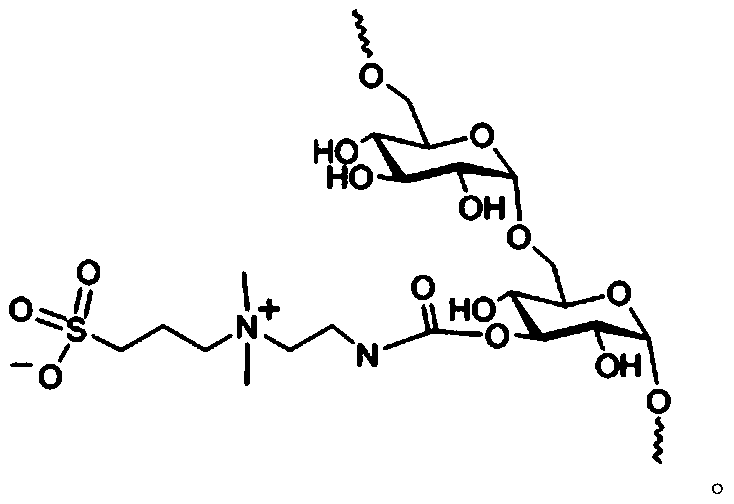

[0031] Example 1: Preparation of Dextran Carboxybetaine (Dex-CB) Hydrogel

[0032] The percentages of components are as follows:

[0033] Carboxybetaine glucan content: 40%

[0034] Sodium tetraborate: 5%

[0035] Distilled water: 55%

[0036] Add 1000 mg of carboxybetaine dextran to a glass bottle containing 0.9 mL of deionized water, ultrasonicate for about 30 minutes until completely dissolved, add 0.125 g of sodium tetraborate to 0.5 mL of water, and add it to the amphoteric dextran after heating and dissolving In the carboxybetaine aqueous solution, the pH of the system was adjusted to 9 with 1 mol / L NaOH aqueous solution. After sonication for 5 minutes, a hydrogel was obtained at the bottom of the glass bottle, which had a transparent texture and good flexibility. In order to make the shape of the gel uniform and complete, it is necessary to transfer the precursor solution to a self-made PTFE cylindrical mold before the cross-linking agent and the amphoteric betaine de...

example 2

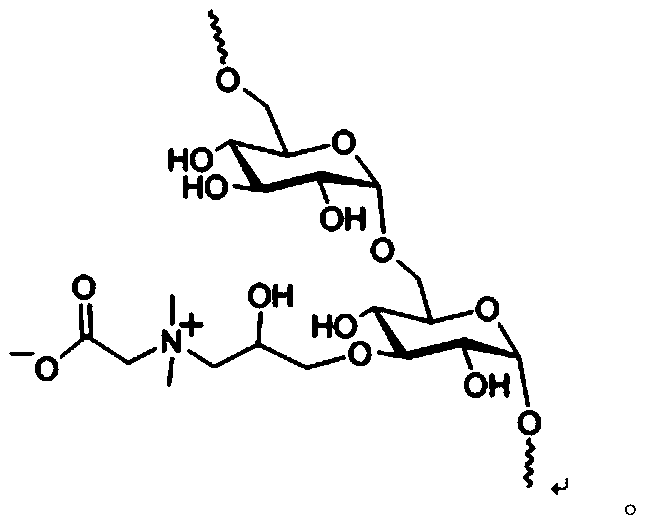

[0037] Example 2: Preparation of Dextran Carboxybetaine (Dex-CB) Hydrogel

[0038] The percentages of components are as follows:

[0039] Amphoteric carboxybetaine glucan content: 15.9%

[0040] N,N-Methylenebisacrylamide: 2.25%

[0041] Distilled water: 81.85%

[0042] Add 0.113 g of carboxybetaine dextran into a glass bottle containing 0.582 mL of deionized water, ultrasonicate for about 30 minutes until completely dissolved, add 0.016 g of N,N-methylenebisacrylamide, and react at a constant temperature of 50 °C for 30 After 2 minutes, the pH of the system was adjusted to 10 with 2 mol / L NaOH aqueous solution. Ultrasonic cross-linking was performed for 5 minutes to obtain a colorless and transparent gel. In order to make the shape of the gel uniform and complete, it is necessary to transfer the precursor solution to a self-made PTFE cylindrical mold before the cross-linking agent and the amphoteric carboxybetaine-dextran solution are gelatinized, seal it, and place the m...

example 3

[0043] Example 3: Preparation of Dextran Carboxybetaine (Dex-CB) Hydrogel

[0044] The percentages of components are as follows:

[0045] Amphoteric carboxybetaine glucan content: 15.7%

[0046] N,N'-bis(acryloyl)cystamine: 3.88%

[0047] Distilled water: 80.42%

[0048] Add 0.113 g of carboxybetaine dextran into a glass bottle containing 0.578 mL of deionized water, ultrasonicate for 30 minutes until completely dissolved, add 0.028 g of N,N-bis(acryloyl) cystamine, and react at a constant temperature of 50 °C for 30 min, adjust the pH of the system to 10 with 2 mol / L NaOH aqueous solution. Ultrasonic cross-linking was performed for 5 minutes to obtain a colorless and transparent gel. In order to make the shape of the gel uniform and complete, it is necessary to transfer the precursor solution to a self-made PTFE cylindrical mold before the crosslinking agent and the amphoteric betaine solution gel, seal the mold and place it in an oven at 50 °C . The reaction was comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com