Regenerated polyethylene material containing phosphogypsum and preparation method thereof

A technology of recycled polyethylene and phosphogypsum, which is applied in the field of preparation of recycled polyethylene materials, can solve the problems of less than 10% comprehensive utilization rate, high comprehensive utilization cost, and loss of mechanical properties, so as to achieve practicality and improve product sensory experience , Consistent appearance and color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

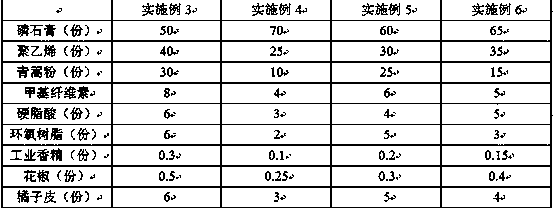

[0045] Weigh the following raw materials in parts by mass:

[0046] Phosphogypsum: 50 parts;

[0047] Polyethylene return material: 25 parts;

[0048] Artemisia annua powder: 10 parts;

[0049] Stearic acid: 4 parts;

[0050] Methylcellulose: 3 parts;

[0051] Epoxy resin: 2 parts;

[0052] Industrial essence: 0.1 parts;

[0053] Zanthoxylum bungeanum: 0.25 parts;

[0054] Orange peel: 3 servings.

[0055] The above raw materials are implemented according to the following steps:

[0056] (1) Calcining the phosphogypsum to remove water until the moisture contained in the phosphogypsum is less than 4% of its mass, and then grinding the phosphogypsum into a 1000-mesh powder;

[0057] (2) Clean and dry the polyethylene material after screening, and then pull the sheet;

[0058] (3) After mixing the materials processed in step 1 and step 2, add 10% of the total mass of the materials and stir together until they are evenly mixed to obtain a semi-finished product;

[0059] ...

Embodiment 2

[0064] Weigh the following raw materials in parts by mass:

[0065] Phosphogypsum: 70 parts;

[0066] Polyethylene return material: 40 parts;

[0067] Artemisia annua powder: 30 parts;

[0068] Stearic acid: 8 parts;

[0069] Methylcellulose: 6 parts;

[0070] Epoxy resin: 6 parts;

[0071] Industrial essence: 0.3 parts;

[0072] Zanthoxylum bungeanum: 0.5 part;

[0073] Orange peel: 6 servings.

[0074] The above raw materials are implemented according to the following steps:

[0075] (1) Calcining the phosphogypsum to remove water until the moisture contained in the phosphogypsum is less than 4% of its mass, and then grinding the phosphogypsum into a 1000-mesh powder;

[0076] (2) Clean and dry the polyethylene material after screening, and then pull the sheet;

[0077](3) After mixing the materials processed in step 1 and step 2, add 10% of the total mass of the materials and stir together until they are evenly mixed to obtain a semi-finished product;

[0078] (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com