Copper phthalocyanine refining device and method

A refining device and refining method technology, applied in chemical instruments and methods, porphine/acrphine, azo dyes and other directions, can solve the problems of difficult environmental protection treatment, large amount of acidic wastewater, and difficulty in resource utilization, etc. The effect of reducing the difficulty of wastewater treatment and reducing the consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1 copper phthalocyanine refining device

Embodiment 11

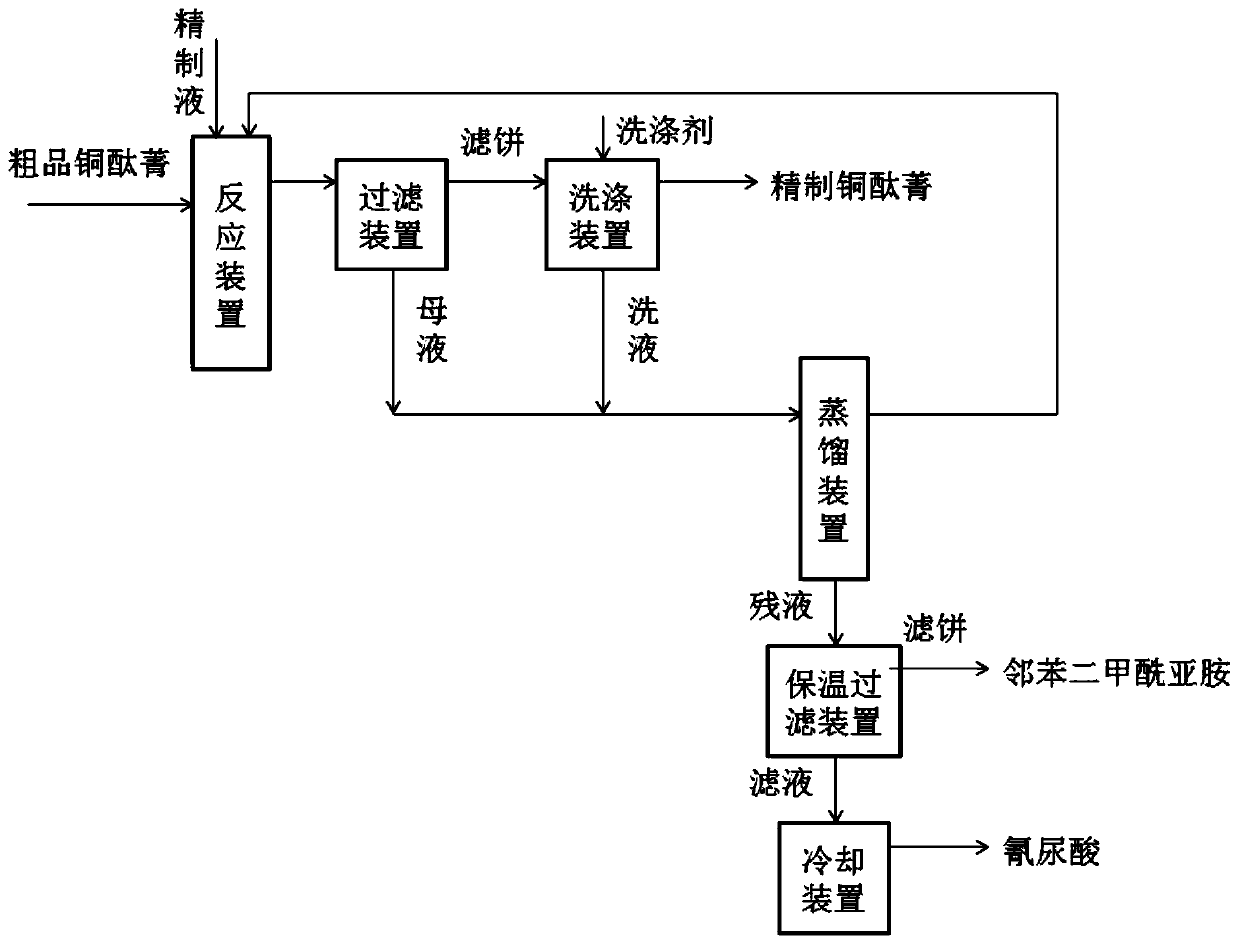

[0071] The schematic diagram of the refining device structure of copper phthalocyanine described in this embodiment is as follows figure 1 shown, including:

[0072] (1) Reaction unit

[0073] The reaction unit includes a reaction device with a heating function. The feed port of the reaction device includes a solid feed port and a liquid feed port. The solid feed port is used to add crude copper phthalocyanine, and the liquid feed port is used to add refined liquid.

[0074] (2) Separation unit

[0075] Described separating unit comprises filtering device and washing device, and filtering device comprises solid discharge port and liquid discharge port, and washing device comprises solid feed port, liquid feed port, solid discharge port and liquid discharge port, the filter device The feed port is connected to the feed port of the reaction device, and the solid feed port of the filter device is connected to the solid feed port of the washing device.

[0076] (3) Post-process...

Embodiment 12

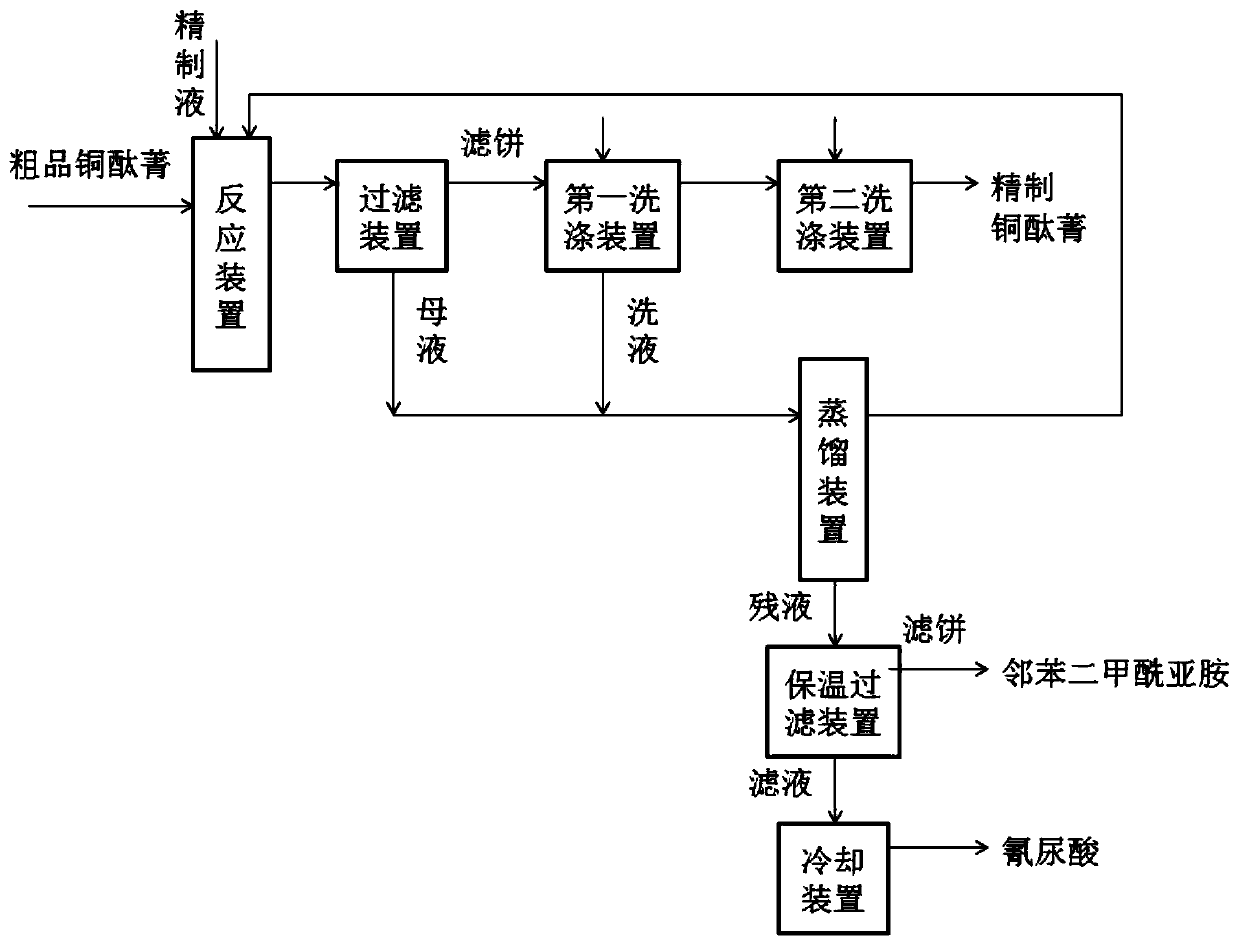

[0080] The schematic diagram of the refining device structure of copper phthalocyanine described in this embodiment is as follows figure 2 Shown, the difference with embodiment 1.1 is:

[0081] Described separating unit comprises filtering device, first washing device and second washing device, and filtering device comprises solid discharge port and liquid discharge port, and two washing devices all comprise solid feed port, liquid feed port, solid discharge port and Liquid discharge port, the feed port of the filter device is connected to the discharge port of the reaction device, the solid discharge port of the filter device is connected to the solid feed port of the first washing device, and the solid discharge port of the first washing device is connected to the second The solids feeding port of the washing device is connected.

[0082] The use process of the refining device described in this embodiment is as follows: add crude copper phthalocyanine to the feed port of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com