Method and device for extracting and preparing battery-grade lithium carbonate from P507 raffinate

A technology of extraction device and raffinate, which is applied in the field of non-ferrous metal hydrometallurgy, can solve the problems of increasing the difficulty of recycling and environmental protection treatment, low purity of lithium products, and failing to reach battery-grade lithium salts, so as to reduce the difficulty of wastewater treatment. , The effect of improving product purity and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

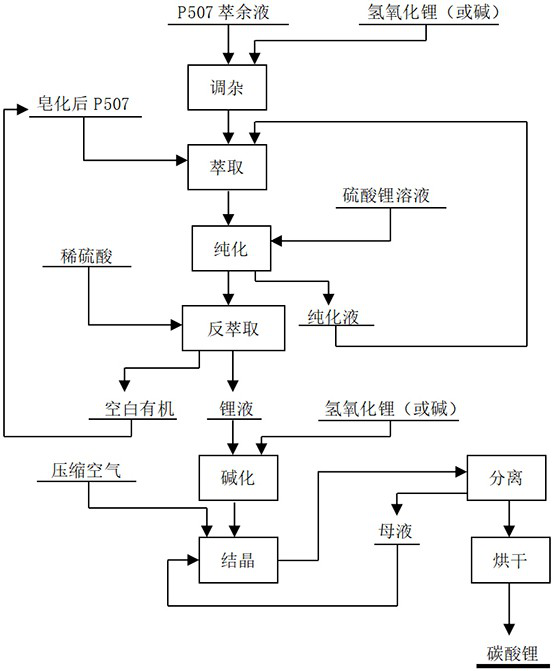

[0028] Implementation mode 1: if figure 1 , a method for extracting and preparing battery-grade lithium carbonate from P507 raffinate, comprising the following steps: blending, extraction, purification, stripping, alkalization, crystallization, separation, and drying. The special features are:

[0029] The blending: first adjust the pH value of the P507 raffinate to 8.5-10.5 with lithium hydroxide or alkali, filter, and keep the filtrate for later use.

[0030] The above-mentioned adjustment of pH value with lithium hydroxide or alkali can be adjusted to 9-10, 8.5-9, 9-9.5, 9.5-10.

[0031] This step can effectively precipitate and remove impurity cations such as nickel, and the experimental data are shown in Table 1.

[0032] Table 1: The effect of pH value on the removal of impurity cations such as nickel by precipitation

[0033]

[0034] The extraction: In the extraction device, mix the saponified P507 with the filtered liquid in the mixing step, and then stand still ...

Embodiment approach 2

[0064] Implementation mode 2: if figure 1 A method for extracting and preparing battery-grade lithium carbonate from P507 raffinate, which is special in that it comprises the following steps:

[0065] a. Blending: first adjust the pH value of the P507 raffinate to 8.5-10.5 with lithium hydroxide or alkali, preferably 9-10, 9.5, filter, and keep the filtrate for later use. It can precipitate and remove impurity cations such as nickel.

[0066] b. Extraction: In the extraction device, mix the saponified P507 with the liquid filtered in the previous step, let stand to separate the phases after mixing, keep the P507 organic phase (loaded organic phase) for use, and detect lithium in the water phase (raffinate) If the ion concentration is less than 1mg / L, it can be sent to wastewater treatment. This step can extract the lithium in the filtrate into the organic phase, reduce the concentration of lithium ions in the raffinate, and reduce the difficulty of wastewater treatment.

[...

Embodiment approach 3

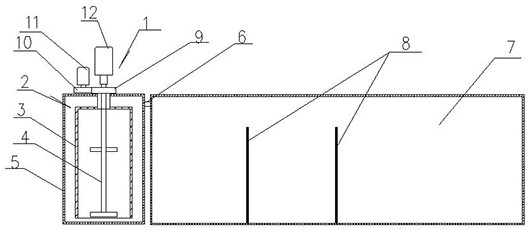

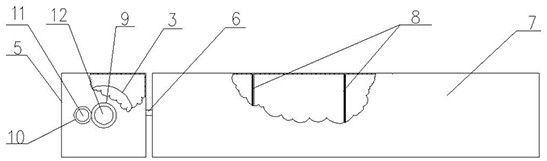

[0074] Implementation mode 3: if Figure 2-4 , an extraction device for extracting and preparing battery-grade lithium carbonate from P507 raffinate, equipped with a stirring chamber 5, which is connected with a clarification chamber 7 through a transition tank 6, and is provided with a stirrer in the stirring chamber 5, and its special feature is that : the stirring chamber 5 is a cube, the clarification chamber 7 is a cuboid, the aspect ratio of the clarification chamber 7 is 4-5:1, the volume ratio of the stirring chamber 5 and the clarification chamber 7 is 1:4.5-5.5, and the mixer consists of a main mixer 1 Composed of auxiliary mixer 2, the main mixer 1 is equipped with stirring blade 4, which is made into a double-layer cross shape, and the stirring body of the auxiliary mixer 2 is made into a cylindrical stirring body 3, which is evenly distributed on the wall of the cylindrical stirring body 3 There is a circular small hole with a diameter of 5-10 mm, and the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com