PH response type degradable intelligent corrosion inhibitor, preparing method and application of PH response type degradable intelligent corrosion inhibitor

A corrosion inhibitor and intelligent technology, which is applied in the field of pH-responsive degradable intelligent corrosion inhibitors, achieves the effects of good biocompatibility, simple response process, and promotion of decomposition products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

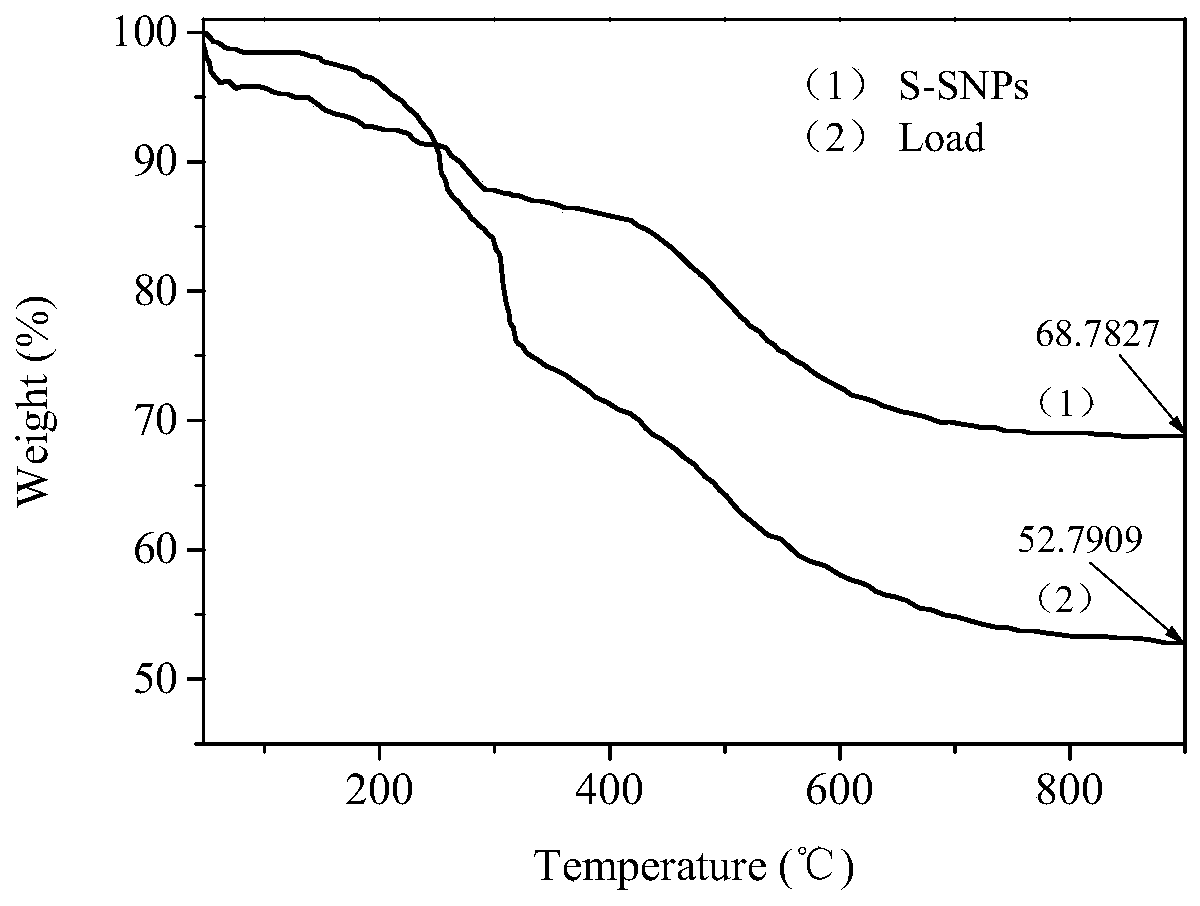

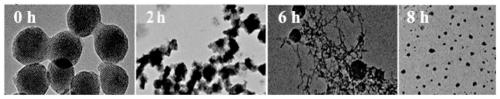

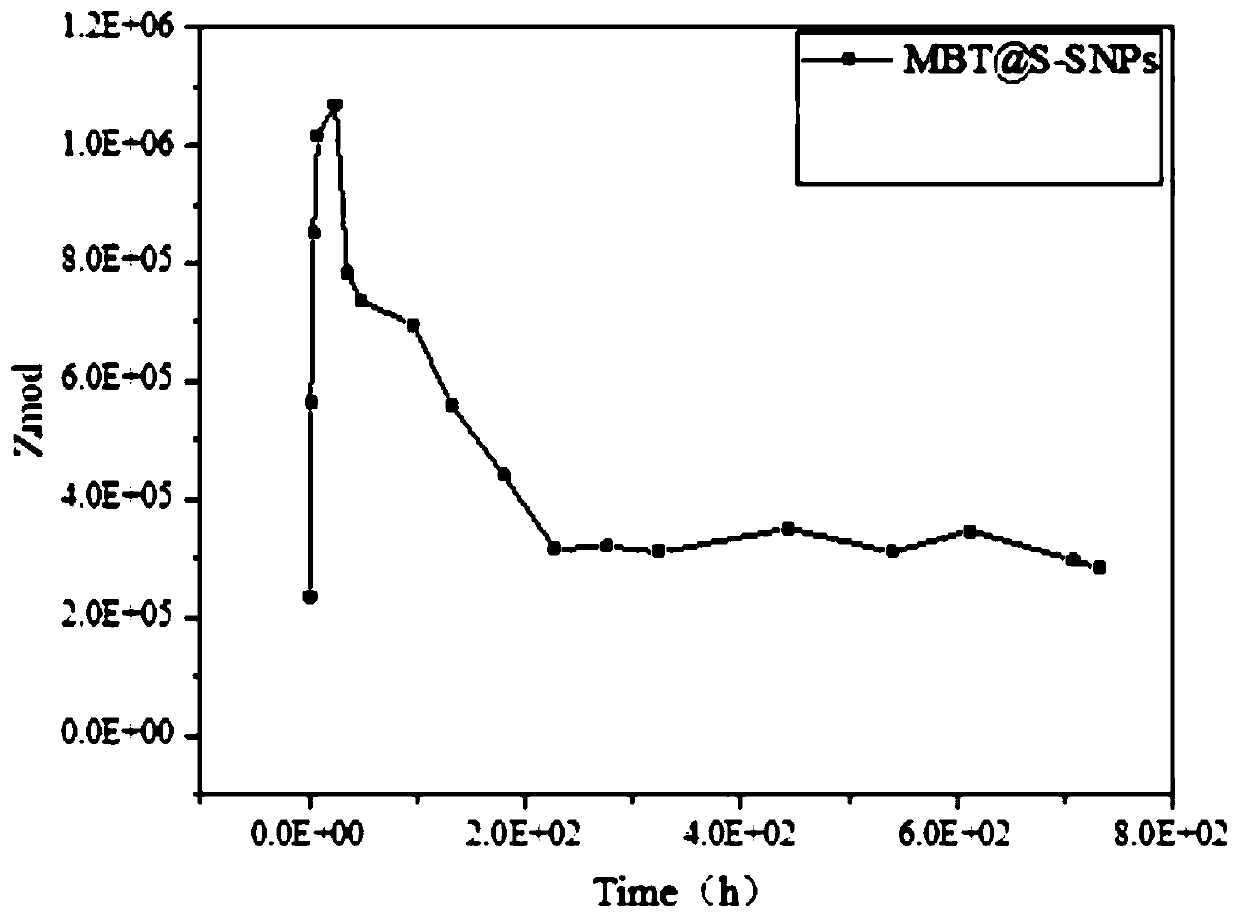

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the pH-responsive degradable intelligent corrosion inhibitor of the present invention, the specific steps are as follows:

[0037] Step 1. Add 2.0-2.68g of terephthalaldehyde and 10-15mL of absolute ethanol into a 100mL three-neck flask, vacuumize and feed nitrogen to maintain a nitrogen atmosphere. Perform magnetic stirring, heat the oil bath to 75-80°C, add 0.8-1.0mL aminopropyltriethoxysilane; condense and reflux for two hours, add an appropriate amount of anhydrous sodium sulfate under stirring conditions, quickly filter and evaporate under low pressure The imino bridged silane precursor was collected.

[0038] Step 2. Mix 0.20-0.3g CTAB, 100mL deionized water and 0.70-1.0mL 2.0-3.0mol / L NaOH solution at 70°C for 1 hour, raise the temperature to 80°C, and mix 0.51-0.931g ethyl orthosilicate and 0.3-1.36 g of the imino-bridged silane precursor is mixed and added dropwise to the solution, and the dropwise addition is completed within 4 minut...

Embodiment 1

[0044] Step 1. Add 2.36g of terephthalaldehyde and 10mL of absolute ethanol into a 100mL three-necked flask, vacuumize and inject nitrogen to maintain a nitrogen atmosphere. Perform magnetic stirring, heat the oil bath to 75°C, add 0.9mL aminopropyl triethoxysilane; condense and reflux for two hours, add an appropriate amount of anhydrous sodium sulfate under stirring conditions, quickly filter and evaporate to collect under low pressure to obtain imine group bridged silane precursor;

[0045] Step 2. Mix 0.23g CTAB, 100mL deionized water and 0.7mL 2.1mol / L NaOH solution at 70°C for 1 hour, raise the temperature to 80°C, and add 0.51g tetraethyl orthosilicate and 0.3g imino bridged silane The precursors were mixed and added dropwise to the solution, and the dropwise addition was completed within 4 minutes, stirred and reacted for 4 hours, washed and dried, and the white product was collected;

[0046] Step 3, add 5.5g / L NH to the white product 4 NO 3 / ethanol solution was ...

Embodiment 2

[0052] Step 1. Add 2.50g of terephthalaldehyde and 11mL of absolute ethanol into a 100mL three-neck flask, vacuumize and inject nitrogen to maintain a nitrogen atmosphere. Perform magnetic stirring, heat the oil bath to 80°C, add 1mL of aminopropyltriethoxysilane; condense and reflux for two hours, add an appropriate amount of anhydrous sodium sulfate under stirring conditions, quickly filter and evaporate to collect under low pressure to obtain the imine group Bridged silane precursors;

[0053] Step 2. Mix 0.23g CTAB, 100mL deionized water and 0.7mL 2.2mol / L NaOH solution at 70°C for 1 hour, raise the temperature to 80°C, and add 0.80g tetraethyl orthosilicate and 0.39g imino bridged silane After the precursors were mixed, they were added dropwise to the solution, and the dropwise addition was completed within 4 minutes. After stirring for 4 hours, the mixture was washed and dried, and the white product was collected.

[0054] Step 3, add 5.5g / L NH to the white product 4 N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com