Permeable anti-cracking road structure and construction method thereof

A road structure, permeable cement technology, applied in the field of traffic engineering, to achieve the effects of reduced cost, thin thickness and strong anti-rutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

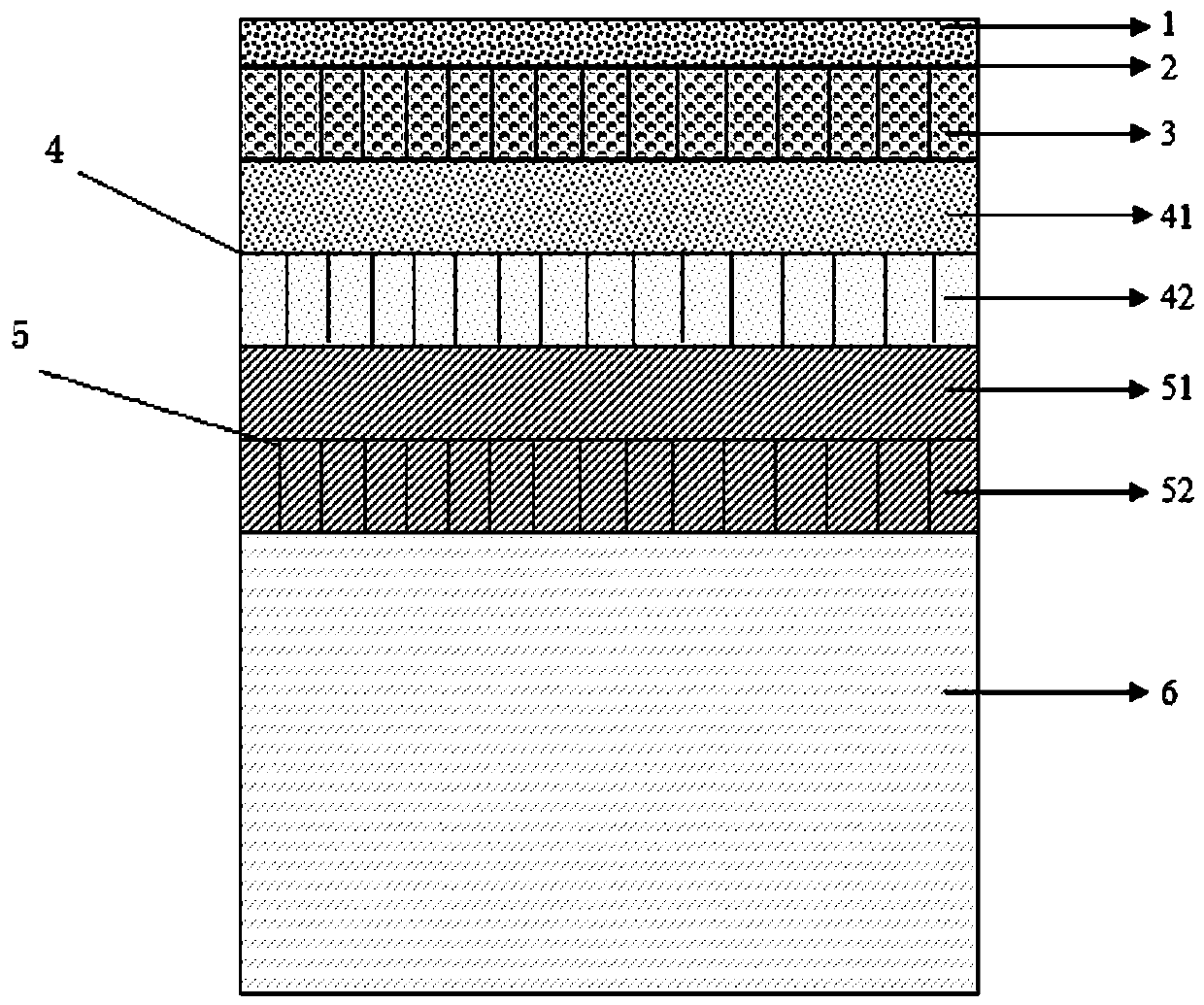

[0041] see figure 1 , a permeable and anti-crack road structure, from top to bottom is the permeable wear layer 1, the geocell open-graded crushed stone permeable cement concrete upper base 3, the coarse sand lower base in the geocell 4, the geocell Plain soil subbase 5 and road bed 6 . The thickness of the water-permeable wear layer layer 1 is generally 4.0-5.0 cm. The water-permeable abrasion surface layer 1 adopts 5cm thick SMA open-graded asphalt mixture, the thickness of the geocell open-graded crushed stone permeable cement concrete upper base 3 is 10cm, and the coarse sand in the geocell lower base 4 is composed of coarse sand in the geocell. The sand 42 and the medium coarse sand 41 laid on the top of the coarse sand 42 in the geocell are composed, and the height of the coarse sand 42 in the geocell is equal to the height of the medium coarse sand 41 and is 10 cm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com