Microstrip antenna, anti-metal electronic tag and manufacturing method of anti-metal electronic tag

A technology of microstrip antenna and antenna, which is applied in the direction of recording carriers, instruments, computer parts and other parts used by machines, can solve the problems of data reading and writing, achieve the effect of reducing size, easy implementation, and improving the reading distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, the specific implementation of the microstrip antenna, electronic tag and electronic tag manufacturing method according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments , structure, feature and effect thereof, detailed description is as follows.

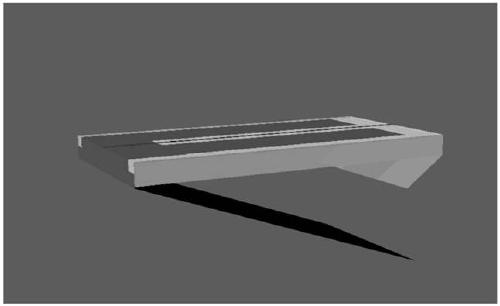

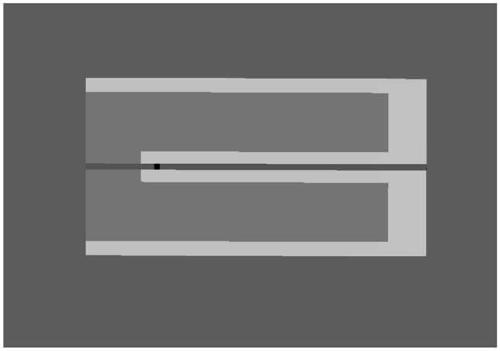

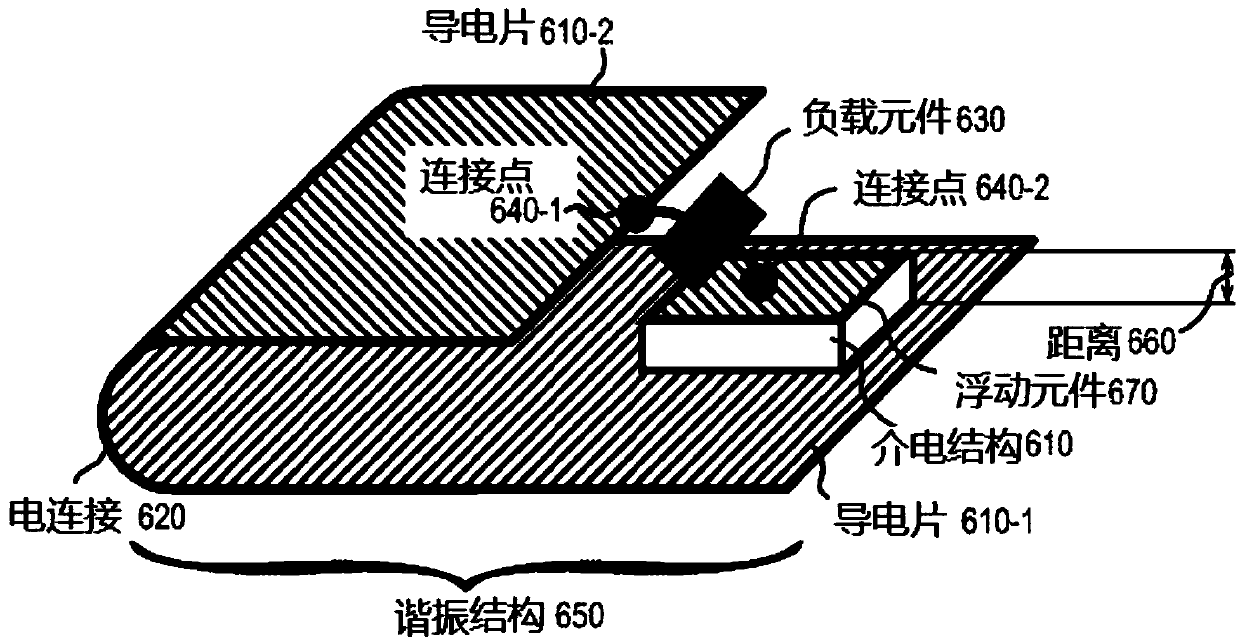

[0070] Such as Figure 2-5 As shown, in the first preferred embodiment of the present invention, the microstrip antenna of the present invention includes a ground plate 20, a radiation sheet including a sub-chip 211 and a sub-chip 212, a medium 26, a feed source 22, a feeder 23, a short circuit sheet 27, feeder sheet 24 and insulating film. Wherein, the medium 26 is substantially a flat cuboid structure, and in this embodiment it is formed of an elastic material, such as silicon rubber. exist image 3 In the XYZ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com