Method for realizing IGZO photocurrent regulation and control based on two-dimensional black phosphorus material

A black phosphorus and construction method technology, applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of complex preparation process of heterojunction devices, small sample size, unstable device performance, etc., and achieve photocurrent intensity and response time Effective, repeatable, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

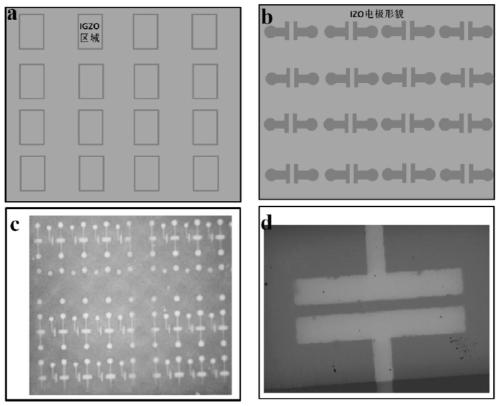

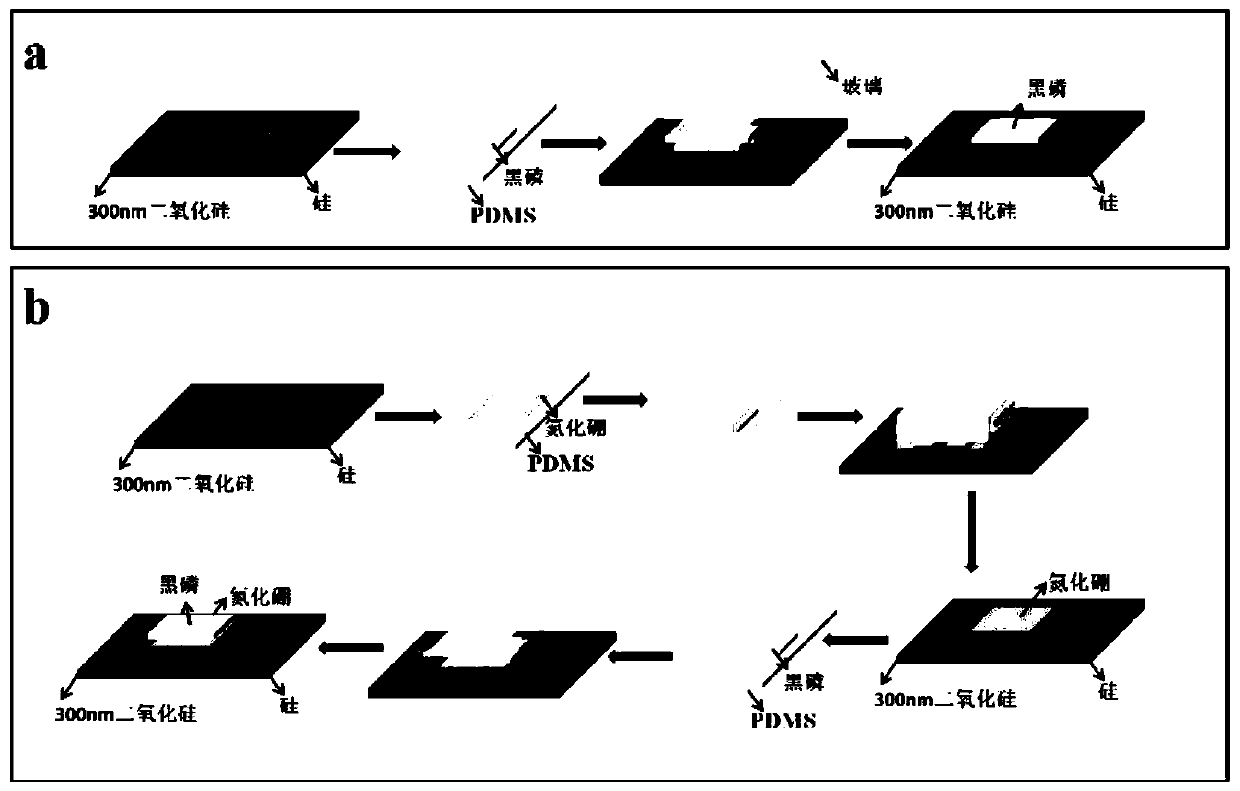

[0060] based on figure 1 Using the mask to prepare IGZO devices, the preparation process includes the following steps:

[0061] (1) Preparing the mask: draw the mask according to the needs of the experiment (such as figure 1 (a) and (b)). In this example, a set of masks are used, one of which is used to prepare the IGZO channel layer (mask I), and the other is used to prepare electrodes on the surface of IGZO (Mask plate II). The channel width of mask plate I is 40um. Find a mask manufacturer for processing (the manufacturer found in this example is a micro-nano scientific research laboratory equipment company), in order to ensure the mask Flatness and thinner thickness, the original material used is a stainless steel plate with a thickness of 3mm;

[0062] (2) Substrate cleaning: In this embodiment, a silicon wafer plated with a 300nm silicon dioxide layer is used as the substrate, and the substrates are placed in acetone, ethanol, and deionized water for 5 minutes in order to rem...

Embodiment 2

[0079] Example 2 Changing the IGZO channel width

[0080] Use mask to prepare IGZO device:

[0081] (1) Preparing the mask: The difference from the mask in Example 1 is that the channel width of the mask I in this embodiment is 80 um; the materials and processing manufacturers are the same;

[0082] (2)~(5): Same as (2)~(5) in Example 1, fabricated an IGZO device with a channel width of 80um; fabricated black phosphorus-IGZO heterogeneous structures with different structures: the same as in Example 1. The preparation method is the same, and four types of black phosphorus-IGZO heterogenes are prepared.

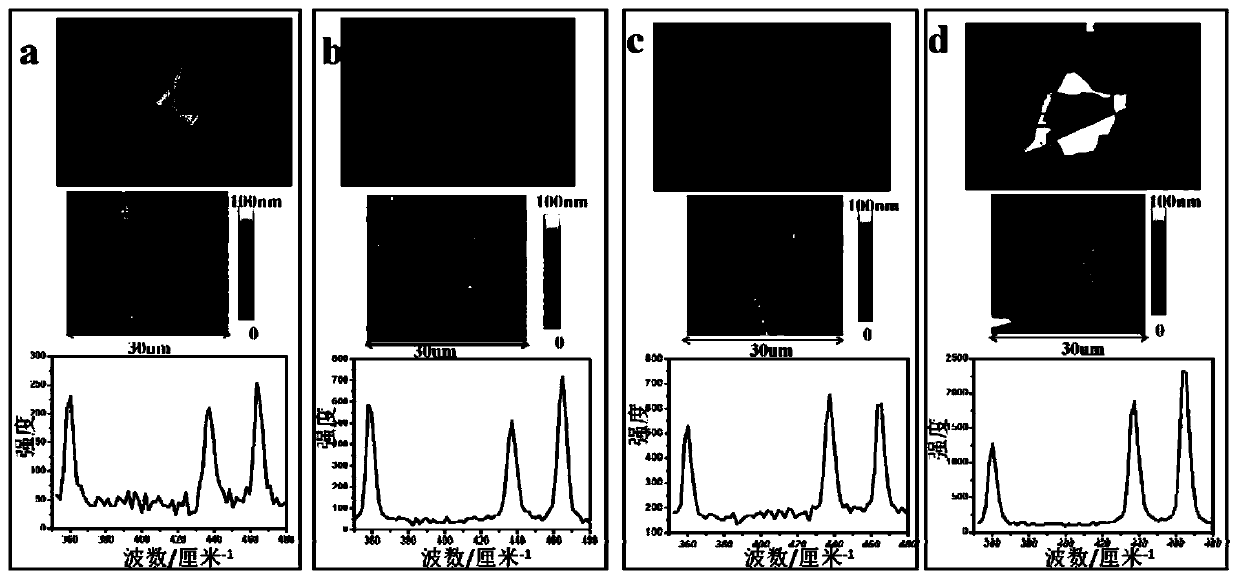

[0083] Characterization of the photocurrent performance of different types of heterojunctions (type I and type III): the photocurrent was tested using the test method in Example 1.

[0084] The test result is like Image 6 : In Type I, that is, after black phosphorus covers the electrodes at both ends of the channel, the photocurrent in the original IGZO decreases, but the decrease is n...

Embodiment 3

[0085] Example 3 Changing the thickness of IGZO channel

[0086] (1)~(2): Same as (1)~(2) in Example 1;

[0087] (3) Use a clamp to fix the stainless steel mask on the surface of the substrate that has been cut in advance and the same size as the mask. By controlling the clamp, the mask and the substrate are in close contact with each other, so as to avoid any channel in the magnetron sputtering process. Infiltrated IGZO; use magnetron sputtering method to deposit IGZO, put the substrate with fixed mask into the magnetron sputtering chamber, evacuate to below 10Pa, and then pass in argon and oxygen, the flow rates of which are respectively 10mL / min and 0.3mL / min, reaction pressure is 400mPa, sputtering power is 1.76W / cm 2 , Sputtering time is 12min; prepare 40nm IGZO channel;

[0088] (4) to (5): the same as in Example 1.

[0089] Preparation of black phosphorus-IGZO heterojunctions with different structures: the same as the preparation method in Example 1, the black phosphorus-IGZO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com