Gas diffusion layer for fuel cell and preparation method thereof

A gas diffusion layer and fuel cell technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as easy flooding, and achieve the effects of improving consistency, simplifying preparation processes, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

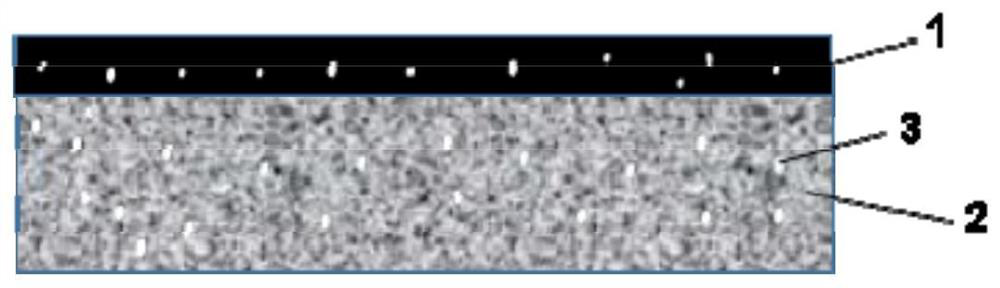

Image

Examples

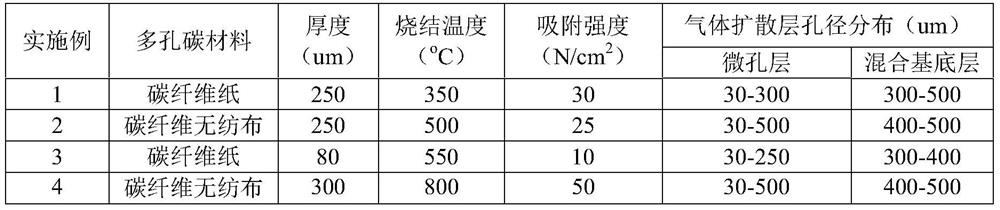

Embodiment 1~4

[0037] A method for preparing a gas diffusion layer,

[0038] 1) Prepare conductive paint with acetylene black as the conductive material, the total weight of solid matter in the conductive paint is 100%, and the conductive paint includes the following raw materials in parts by weight: conductive material 80, adhesive 30, pore-forming agent 4wt %, the pore-forming agent is a mixture of ammonium chloride, ammonium bicarbonate and ammonium oxalate, and the average particle size of the pore-forming agent is 500 μm; the binder is a mixture of sodium hydroxymethyl cellulose and polyethylene glycol.

[0039] 2) placing the porous carbon material on a base platform that has adsorption and can be continuously transported;

[0040] 3) Coat the above-mentioned conductive paste on the non-adsorption surface of the porous carbon material. The adsorption strength during the coating process is shown in Table 1. The abutment rotates at a constant speed to continuously transport the coated ma...

Embodiment 5

[0046] A method for preparing a gas diffusion layer,

[0047]1) Prepare a conductive coating with acetylene black as a conductive material. The total weight of solid matter in the conductive coating is 100%, and the conductive coating includes the following raw materials in parts by weight: conductive material 60, adhesive 10, pore-forming agent 1wt %; The pore-forming agent is ammonium chloride, the average particle size of the pore-forming agent is 200 μm, and the binder is sodium hydroxymethyl cellulose.

[0048] 2) Place a porous carbon material with a thickness of 100 μm on a base platform that has adsorption and can be continuously transported;

[0049] 3) Coat the above-mentioned conductive paste on the non-adsorption surface of the porous carbon material, and the adsorption strength during the coating process is 30N / cm 2 , the abutment rotates at a constant speed to continuously convey the coated material, and the mass ratio of the conductive paste to the porous carbo...

Embodiment 6

[0052] A method for preparing a gas diffusion layer,

[0053] 1) prepare conductive paint with acetylene black as conductive material, the total weight of solid matter in the conductive paint is 100%, and described conductive paint comprises the raw material of following weight portion content: conductive material 90, bonding agent 40, carbon fiber 20, make The pore-forming agent is 5 wt%, the pore-forming agent is ammonium bicarbonate, and the average particle size of the pore-forming agent is 600 μm; the binding agent is polyethylene glycol.

[0054] 2) Place a porous carbon material with a thickness of 300 μm on a base platform that has adsorption and can be continuously transported;

[0055] 3) Coat the above-mentioned conductive paste on the non-adsorption surface of the porous carbon material, and the adsorption strength during the coating process is 30N / cm 2 , the abutment rotates at a constant speed to continuously convey the coated material, and the mass ratio of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com