Process method for preparing 3-acetyl-1-propanol

A technology of acetylpropanol and process method, applied in the direction of chemical method for reacting liquid and gas medium, heterocyclic compound preparation, chemical instrument and method, etc., can solve the problem of low reaction efficiency, high cost, reactant and catalyst Small contact area and other problems, to achieve the effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

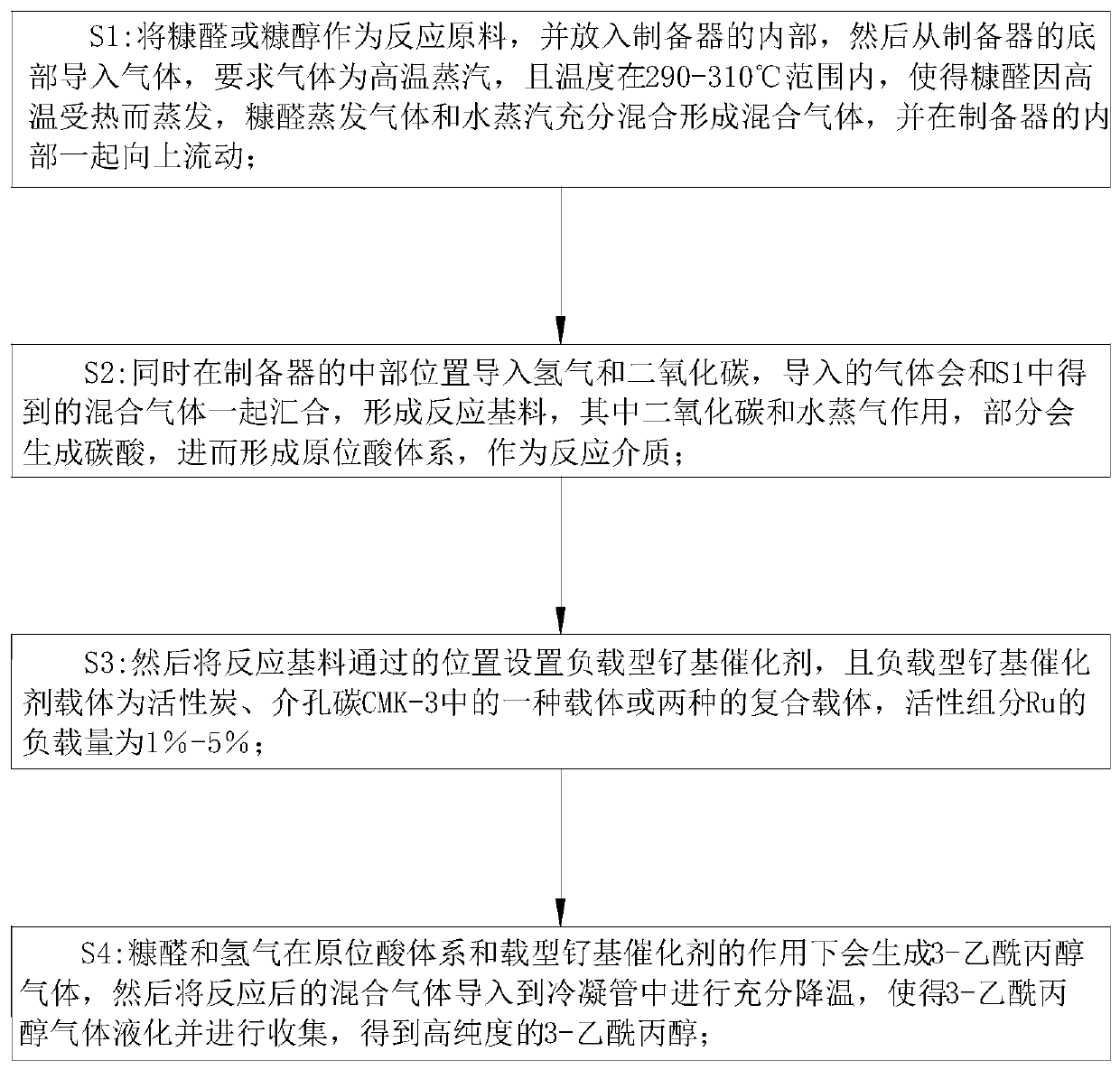

Method used

Image

Examples

Embodiment approach

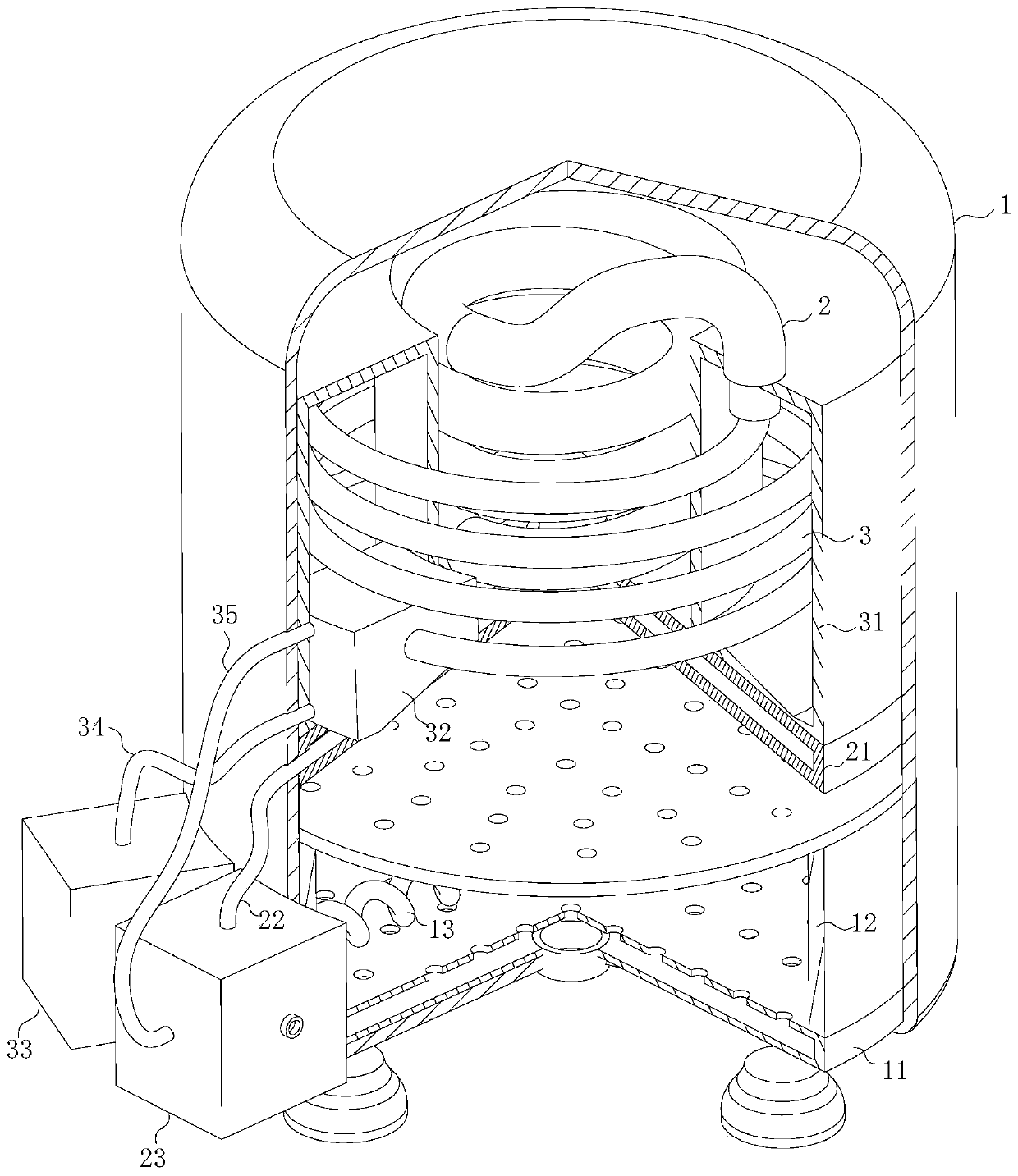

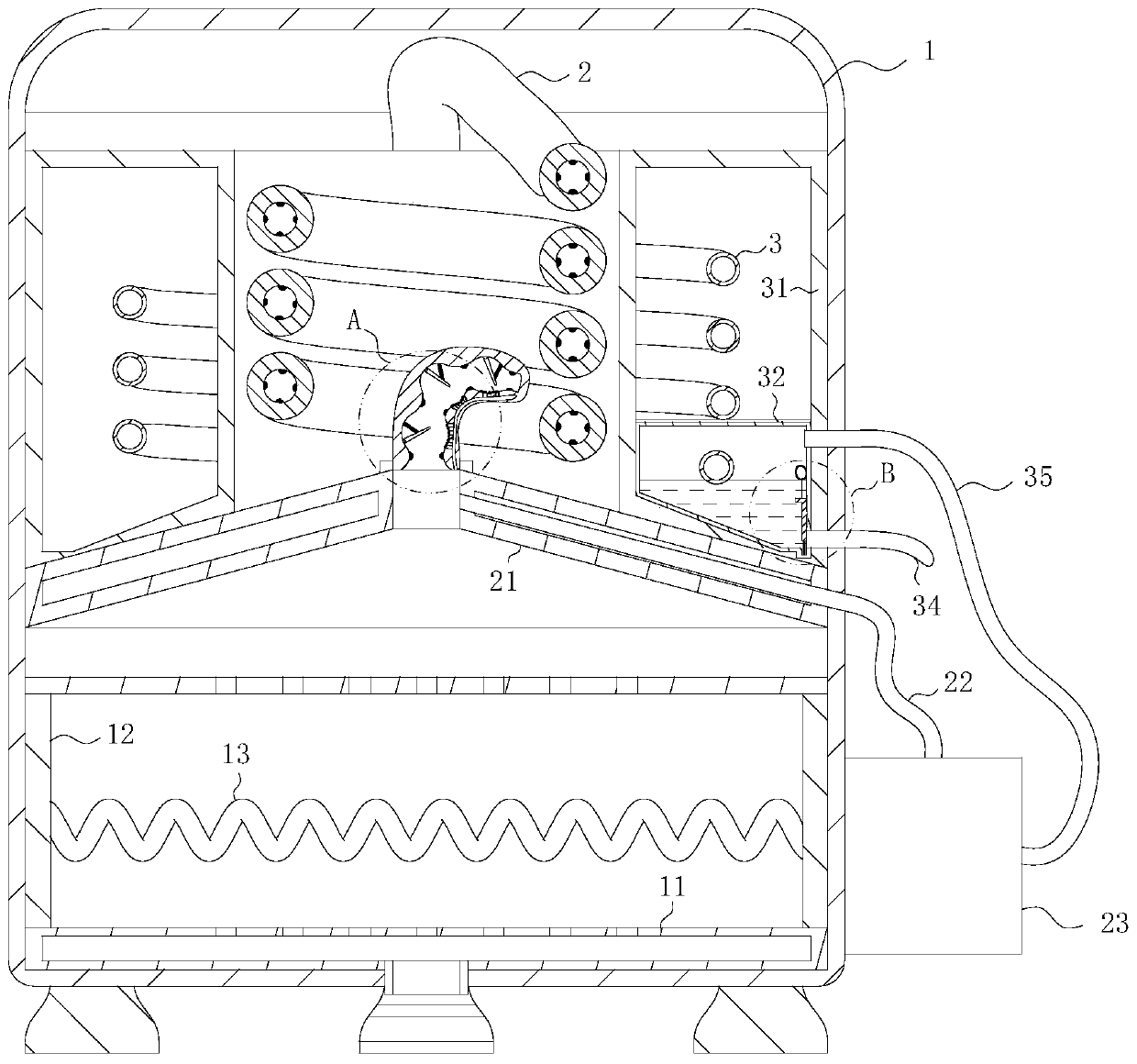

[0034] As an embodiment of the present invention, the baffle 21 is designed in a conical structure, and the arc side of the baffle 21 is firmly connected with the inner arc surface of the tank body 1; the inside of the baffle 21 is provided with a condensation chamber , and the inside of the condensation chamber is filled with condensate; when working, the baffle 21 is designed as a conical structure, which is convenient for the mixed gas to flow into the air guide hole. , to avoid the higher temperature in the reaction tube 2 above the baffle plate 21, which is not conducive to the partial condensation of the steam, and the initial cooling of the reaction product together, thereby affecting the purity of the product. On the other hand, the contact area between the mixed gas and the condensation plate is increased, so that The steam in the mixed gas can be partially condensed to prevent excessive water vapor from interfering with the synthesis reaction in the reaction tube 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com