Preparation and application of molybdenum-doped cobalt selenide foamed nickel composite electrode for electrolyzing water

A composite electrode, nickel foam technology, applied in the field of electrolysis of water, can solve the problems of high cost, scarcity of scarce resources for large-scale applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

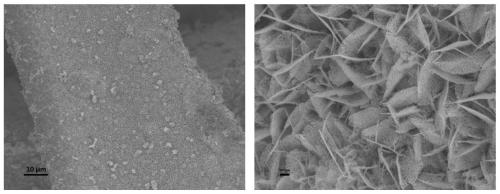

Image

Examples

Embodiment 1

[0024] A preparation method of a molybdenum-doped cobalt selenide foam nickel composite electrode, comprising the following steps:

[0025] (1) Preparation of foamed nickel: Cut the foamed nickel (NF) into a certain size (2cm×1cm), then ultrasonically clean the foamed nickel in 1M HCl solution, ultrapure water, and acetone for 20 minutes, and dry it for use.

[0026] (2) Preparation of Co(OH) 2 NS@NF: Electrodeposition is carried out on the surface of NF. During the electrodeposition process, 0.1M Co(NO 3 ) 2 As an electrolyte, use a current density of 1.0mA cm at room temperature -2 Electrodeposition of Co(OH) on NF by galvanostatic electrolysis 2 Nanosheets (Co(OH) 2 NS@NF) for 30min, and the product was dried in a drying oven at 60°C for 24 hours.

[0027] (3) Preparation of Mo-CoSe 2 NS@NF

[0028] Na with a molar ratio of 0.6:1 2 MoO 4 2H 2 O and Co(NO 3 ) 2 ·6H 2 O was dissolved in 30ml of ultrapure water, stirred for 30min and then transferred to a 50mL Te...

Embodiment 2

[0030] A preparation method of a molybdenum-doped cobalt selenide foam nickel composite electrode, comprising the following steps:

[0031] (1) Preparation of foamed nickel: Cut the foamed nickel (NF) into a certain size (2cm×1cm), then ultrasonically clean the foamed nickel in 1.5M HCl solution, ultrapure water, and acetone for 30 minutes, and dry it for use.

[0032] (2) Preparation of Co(OH) 2 NS@NF: Electrodeposition is carried out on the surface of NF. During the electrodeposition process, 0.1M Co(NO 3 ) 2 As the electrolyte, the current density used at room temperature is 2.0mA cm -2 Electrodeposition of Co(OH) on NF by galvanostatic electrolysis 2 Nanosheets (Co(OH) 2 NS@NF) for 20min, and the product was dried in a drying oven at 60°C for 24 hours.

[0033] (3) Preparation of Mo-CoSe 2 NS@NF

[0034] Na with a molar ratio of 0.6:1 2 MoO 4 2H 2 O and Co(NO 3 ) 2 ·6H2 O was dissolved in 30ml of ultrapure water, stirred for 30min and then transferred to a 50m...

Embodiment 3

[0036] A preparation method of a molybdenum-doped cobalt selenide foam nickel composite electrode, comprising the following steps:

[0037] (1) Preparation of foamed nickel: Cut the foamed nickel (NF) into a certain size (2cm×1cm), then ultrasonically clean the foamed nickel in 2.5M HCl solution, ultrapure water, and acetone for 30 minutes, and dry it for use.

[0038] (2) Preparation of Co(OH) 2 NS@NF: Electrodeposition is carried out on the surface of NF. During the electrodeposition process, 0.1M Co(NO 3 ) 2 As an electrolyte, use a current density of 2.5mA cm at room temperature -2 Electrodeposition of Co(OH) on NF by galvanostatic electrolysis 2 Nanosheets (Co(OH) 2 NS@NF) for 15 min, and the product was dried in a drying oven at 60°C for 24 hours.

[0039] (3) Preparation of Mo-CoSe 2 NS@NF

[0040] Na with a molar ratio of 0.4:1 2 MoO 4 2H 2 O and Co(NO 3 ) 2 ·6H 2 O was dissolved in 30ml ultrapure water, stirred for 30min and then transferred to a 50ml Te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com