Sampling system for tungsten hexafluoride metal element analysis and using method thereof

A technology for metal element analysis and tungsten hexafluoride, which is applied in the direction of sampling, analyzing materials, sampling devices, etc., can solve the problems of long time consumption, calculation weight gain, large error, etc., achieve a stable and safe volatilization process, and avoid local space negative pressure , The effect of improving the efficiency of sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

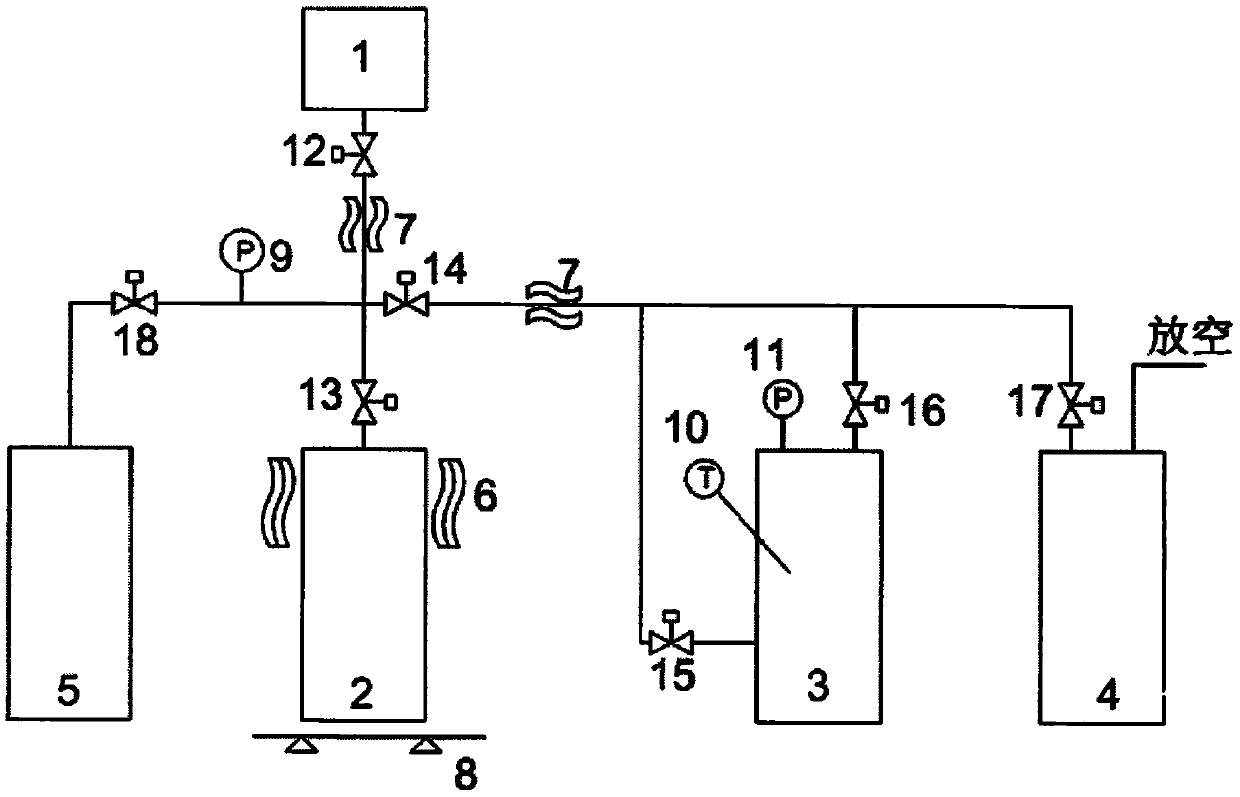

[0028] Such as figure 1As shown, a sampling system for the analysis of tungsten hexafluoride metal elements, including tungsten hexafluoride container, high-purity gas source, sampling device, vacuum device, collection device, valves and pipelines, tungsten hexafluoride container 1 Through the pipeline, it is connected with high-purity gas source 5, sampling device 2, collection device 3, and vacuum device 4 in sequence. The sampling port of tungsten hexafluoride container 1 is equipped with No. I valve 12, and the outlet pipeline of high-purity gas source 5 is equipped with VII No. valve 18 and No. I pressure gauge 9, No. II valve 13 is installed on the sampling device 2, thermometer 10 and No. II pressure gauge 11 are installed on the collection device 3, No. IV valve 15 is installed on the bottom of the collection device 3, and V is installed on the top No. valve 16; No. VI valve 17 is installed in the vacuum device 4; No. III valve 14 is arranged on the pipeline going to t...

Embodiment 2

[0036] Collection device 3 is an adsorption tower filled with potassium fluoride adsorbent, and the others are the same as in embodiment 1

[0037] Steps:

[0038] (1) Evacuation of the collection device: turn on the vacuum device 4, turn on the collection device 3 to control the temperature, and confirm that the temperature T in the collection device 3 is 20-30°C. Open the No. VI valve 17 and the No. V valve 16 in sequence, and the evacuation collection device 3 to the No. II pressure gauge 11 is -90kPa, and then close the No. V valve 16 and the No. VI valve 17 in turn.

[0039] (2) Sampling device replacement and evacuation: open No. II valve 13, No. III valve 14, open No. VII valve 18 to fill the sampling device 2 and the pipeline with purge gas; close VII valve 18, open VI No. valve 17, Evacuate the sampling device 2 and the pipeline; repeat the blowing and pumping operations 10 times, the last time the system is evacuated until the No. I pressure gauge 9 is -90kPa, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com