Preparation method of porous NH2-UiO-66-d/indium zinc sulfide composite visible-light-induced photocatalyst

A technology of nh2-uio-66-d and nh2-uio-66, which is applied in the direction of organic compound/hydride/coordination complex catalyst, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve hydrothermal stability In order to achieve the effect of improving photocatalytic hydrogen production activity, high repeatability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

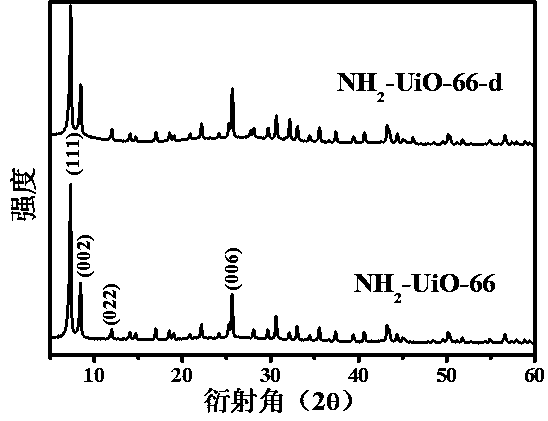

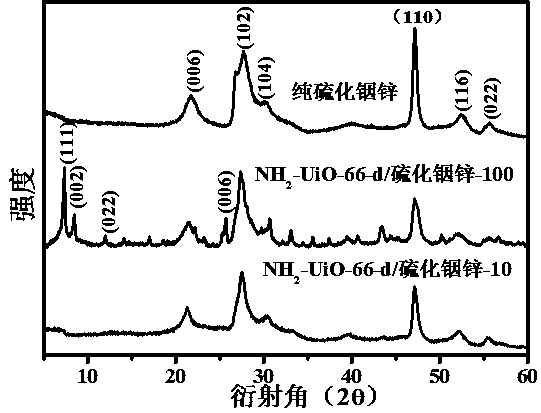

[0022] (1) NH 2 -Preparation of UiO-66: Dissolve 0.2332 g of zirconium chloride and 0.1812 g of 2-aminoterephthalic acid in 50 mL of N,N-dimethylformamide, stir and dissolve the solution, and transfer the solution to polytetrafluoroethylene In vinyl lining, solvothermal reaction at 90°C for 24 h, after the hydrothermal kettle was cooled to room temperature, the product was centrifuged and washed with N,N-dimethylformamide and anhydrous methanol to obtain NH 2 -UiO-66.

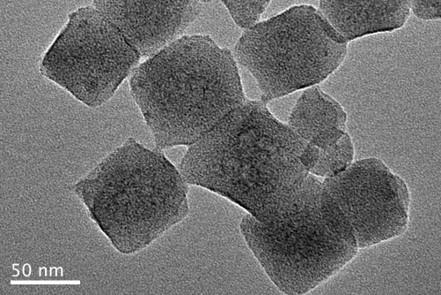

[0023] (2) NH 2 - Preparation of UiO-66-d: Dissolve 50 mg of silver nitrate and 50 mg of potassium persulfate in 20 mL of acetonitrile. After ultrasonic dissolution, the prepared 150 mg of NH 2 - Add UiO-66 to the above solution, put it in an oil bath at 150°C for 40 minutes, then quickly put the reactor into the ice-water mixture, after a period of time, use deionized water and ethanol as detergents to wash the product centrifugally, get porous NH 2 -UiO-66, which is NH 2 -UiO-66-d.

[0024] (3) NH 2 - ...

Embodiment 2

[0026] (1) NH 2 -Preparation of UiO-66: Dissolve 0.2332 g of zirconium chloride and 0.1812 g of 2-aminoterephthalic acid in 50 mL of N,N-dimethylformamide, stir and dissolve the solution, and transfer the solution to polytetrafluoroethylene In vinyl lining, solvothermal reaction at 90°C for 24 h, after the hydrothermal kettle was cooled to room temperature, the product was centrifuged and washed with N,N-dimethylformamide and anhydrous methanol to obtain NH 2 -UiO-66.

[0027] (2) NH 2 - Preparation of UiO-66-d: Dissolve 50 mg of silver nitrate and 50 mg of potassium persulfate in 20 mL of acetonitrile. After ultrasonic dissolution, the prepared 150 mg of NH 2 - Add UiO-66 to the above solution, put it in an oil bath at 150°C for 40 minutes, then quickly put the reactor into the ice-water mixture, after a period of time, use deionized water and ethanol as detergents to wash the product centrifugally, get porous NH 2 -UiO-66, which is NH 2 -UiO-66-d.

[0028] (3) NH 2 - ...

Embodiment 3

[0030] (1) NH 2 -Preparation of UiO-66: Dissolve 0.2332 g of zirconium chloride and 0.1812 g of 2-aminoterephthalic acid in 50 mL of N,N-dimethylformamide, stir and dissolve the solution, and transfer the solution to polytetrafluoroethylene In vinyl lining, solvothermal reaction at 90°C for 24 h, after the hydrothermal kettle was cooled to room temperature, the product was centrifuged and washed with N,N-dimethylformamide and anhydrous methanol to obtain NH 2 -UiO-66.

[0031] (2) NH 2 - Preparation of UiO-66-d: Dissolve 50 mg of silver nitrate and 50 mg of potassium persulfate in 20 mL of acetonitrile. After ultrasonic dissolution, the prepared 150 mg of NH 2 - Add UiO-66 to the above solution, put it in an oil bath at 150°C for 40 minutes, then quickly put the reactor into the ice-water mixture, after a period of time, use deionized water and ethanol as detergents to wash the product centrifugally, get porous NH 2 -UiO-66, which is NH 2 -UiO-66-d.

[0032] (3) NH 2 - ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com