A low-cost and long-life slab continuous casting tundish turbulator preparation method

A slab continuous casting, low-cost technology, applied in the direction of casting equipment, casting melt container, manufacturing tools, etc., can solve the problems of difficult processing of tundish turbulence controller, high cost, floating quality stability of waste magnesia carbon bricks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

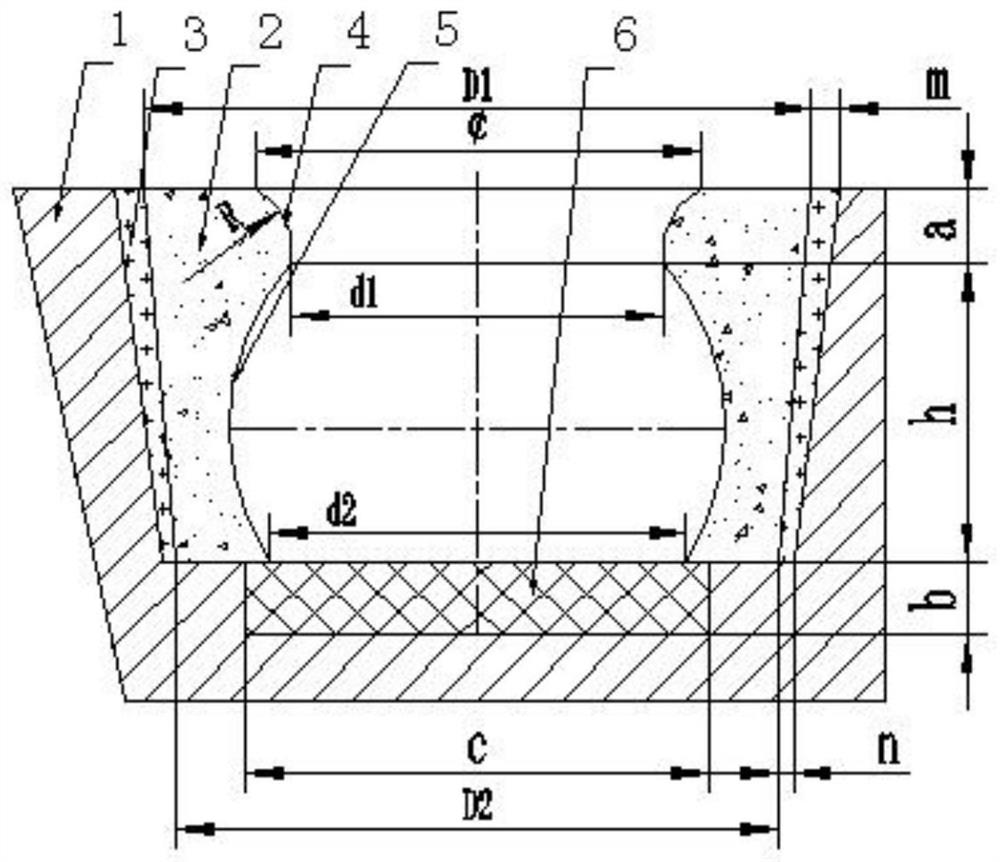

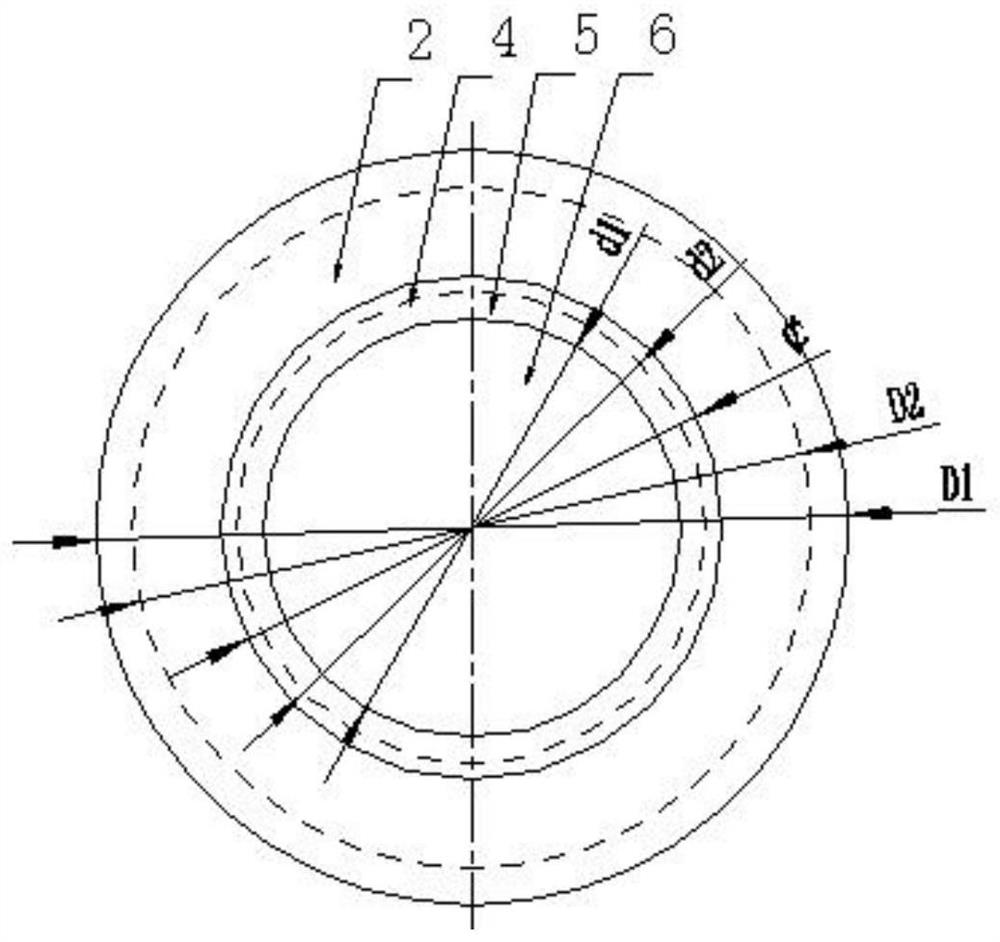

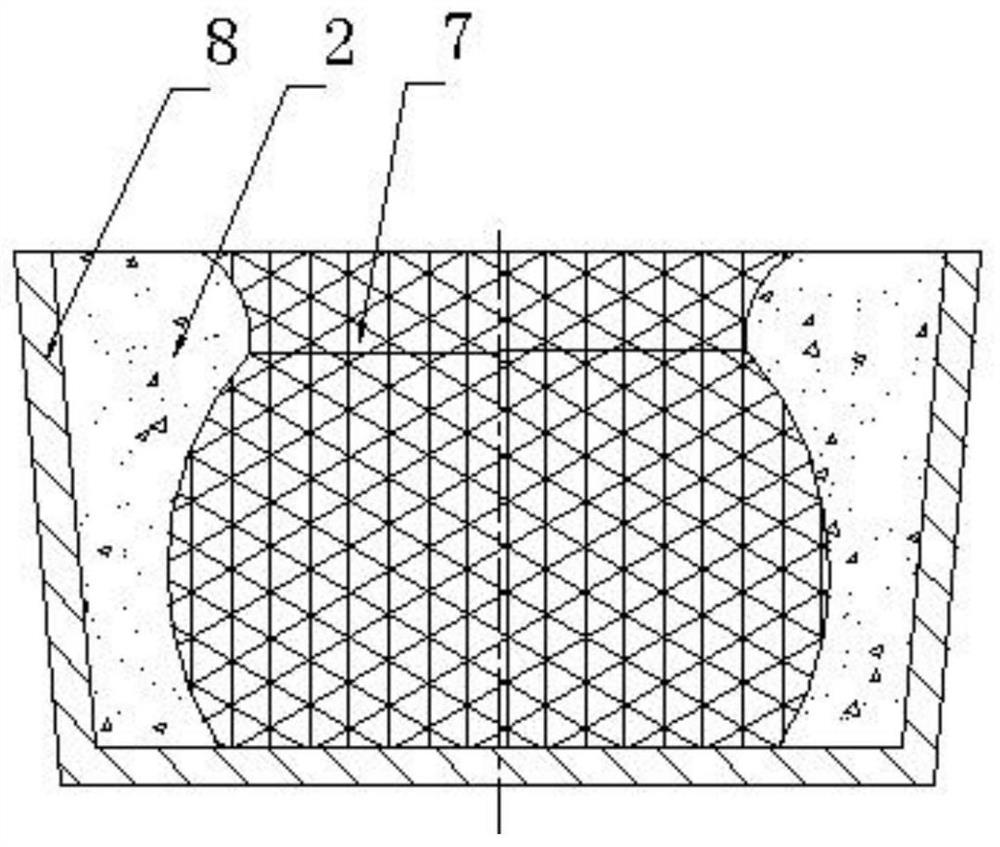

[0076] like figure 1 , figure 2 , image 3 As shown, a low-cost and high-life slab continuous casting tundish turbulence controller is composed of a shell 1, a sleeve core 2, and a bottom plate 6. The bottom plate 6 is positioned on the bottom of the inner cavity of the shell 1, and the bottom of the sleeve core 2 Positioned on the bottom plate 6, and the longitudinal centerline of the sleeve core 2 coincides with the longitudinal centerline of the inner cavity of the shell 1, the joint surface between the bottom plate 6 and the shell 1 and the bottom plate 6 and the sleeve core 2 is coated with 1.5mm thick magnesium Fireclay, there is a joint 3 between the shell 1 and the sleeve core 2. The sleeve core is a conical prefabricated part with a special inner cavity shape based on the research and design of the water model experiment. It adopts a disposable foam inner mold and recycled magnesium carbon High-quality castables are poured and formed, and the bottom plate is a whol...

Embodiment 2

[0088] As described in Example 1, the difference is:

[0089] The sleeve core 2 of the turbulent flow controller, the diameter D1 of the upper bottom surface of the round table is 750mm, and the diameter D2 of the lower bottom surface of the round table is 665mm; The diameter ¢ is 500mm, the arc radius R is 80mm, the height a of the upper part 4 of the inner cavity of the sleeve core 2 is 100mm; the diameter d1 of the upper opening of the lower part 5 of the inner cavity of the sleeve core 2 is 440mm, and the diameter d2 of the lower opening is 480mm. The height h of the cavity lower part 5 is 350 mm.

[0090] The sleeve core 2 is casted and formed by regenerated magnesia-carbon castables, and the regenerated magnesia-carbon castables used for the sleeve core 2 are composed of the following materials by weight percentage: regenerated waste magnesia-carbon bricks with a particle size of 3mm2 o 3 Micro powder 5.0%, pure calcium aluminate cement 3.8%, sodium tripolyphosphate 0.1...

Embodiment 3

[0100] As described in Example 1, the difference is:

[0101] The sleeve core 2 of the turbulent flow controller, the diameter D1 of the upper bottom surface of the round table is 730mm, and the diameter D2 of the lower bottom surface of the round table is 650mm; The diameter ¢ is 490mm, the arc radius R is 77mm, the height a of the upper part 4 of the inner cavity of the sleeve core is 90mm; the diameter d1 of the upper opening of the lower part 5 of the inner cavity of the sleeve core is 430mm, and the diameter d2 of the lower opening is 470mm. 5 has a height h of 330 mm.

[0102] The bottom surface of the bottom plate 6 is square, the side length c is 510 mm, and the thickness b is 100 mm.

[0103] The width of the joining seam 3 is large at the top and small at the bottom, the width m of the upper part is 12 mm, and the width n of the bottom part is 7 mm.

[0104] The sleeve core 2 is casted and formed by regenerated magnesia-carbon castables, and the regenerated magnesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com