High-performance honeycomb ceramic heat accumulator and preparation process thereof

A technology of honeycomb ceramics and preparation process, which is applied in the field of honeycomb ceramic regenerator and its preparation process. Performance and damage resistance, increase the hole wall density, improve the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

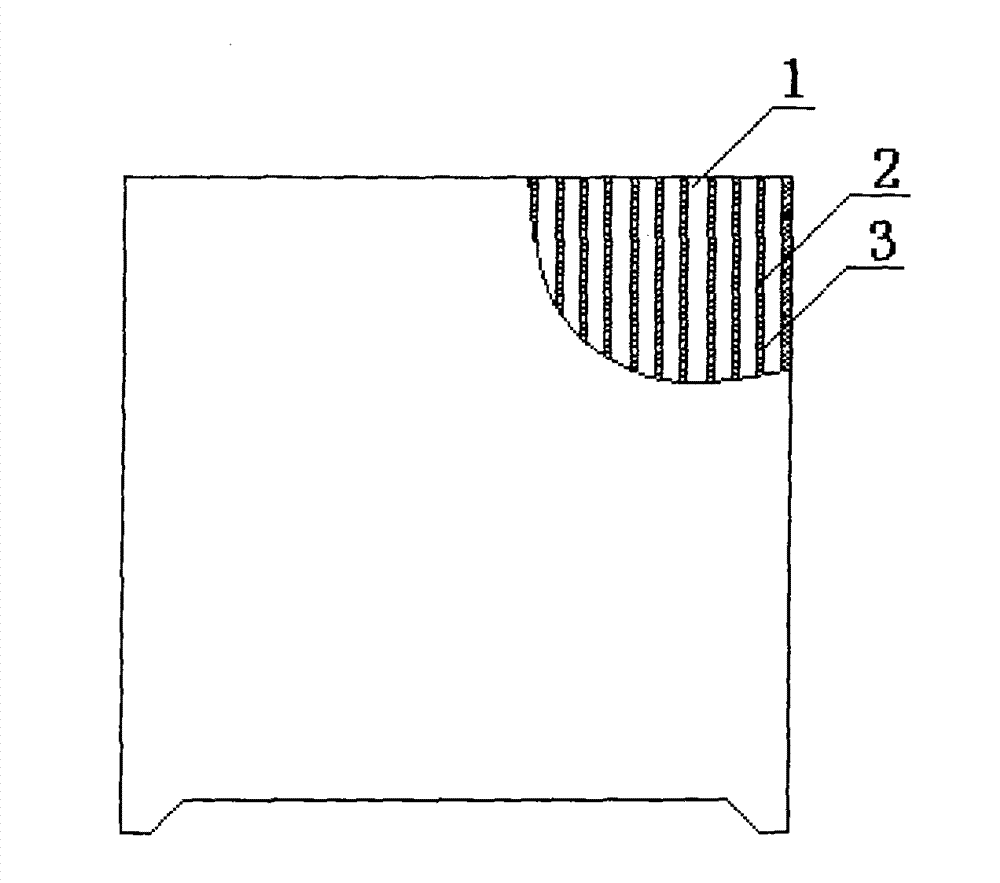

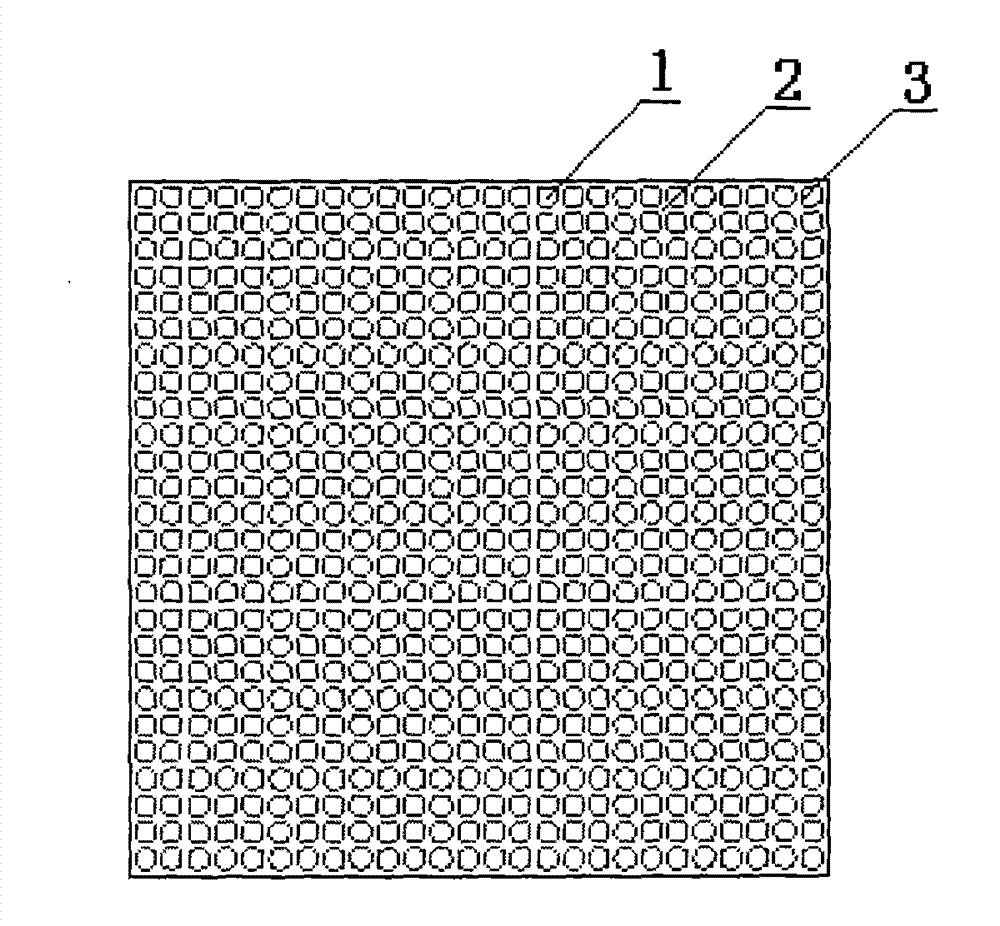

[0019] There are two methods for the preparation of the above-mentioned honeycomb ceramic regenerator: the first method includes batching, trapped material, mud grinding, extrusion molding, microwave baking, ceramic substrate immersion, oven baking, green body shaping and high temperature The step of firing; the process of mode 2 sequentially includes the steps of batching, trapping, crushing, extruding, microwave baking, oven baking, green body shaping, high temperature firing, and ceramic matrix soaking.

[0020] The specific operation steps of the process of mode one are as follows:

[0021] 1. Ingredients: According to the formula of ceramic materials, according to the amount of single stirring and mixing, calculate the dosage of various raw materials, select various raw materials with suitable particle size and components that meet the requirements, and weigh various raw materials according to the calculated dosage. Stir in a blender until the mixture is uniform, then add...

Embodiment 1~3

[0032] Embodiments 1 to 3: According to the process of mode one, the hole wall permeable layer 3 is after the microwave baking step, and the ceramic substrate 2 is respectively placed in a concentration of 25 (wt)%, 30 (wt)% or 40 (wt) % aluminum dihydrogen phosphate aqueous solution for 1 hour, take it out and blow it with high-pressure air, dry it in the shade, and then put it into the oven for baking, and it is formed by drying. Compared with the heat storage body without soaking treatment, the matrix density of the pore wall of the soaked heat storage body is increased by 5%, 8% and 11% respectively, and the heat storage body is resistant to heat along the parallel and vertical directions of the honeycomb cells 1. The compressive strength is increased by 0.5 times, 0.8 times and 1 times respectively.

Embodiment 4~6

[0033] Embodiments 4-6: According to the process of mode two, the permeable layer 3 of the hole wall is after the high-temperature firing step, and the ceramic substrate 2 is respectively placed in a concentration of 30 (wt)%, 45 (wt)% or 60 (wt) % phosphoric acid aqueous solution for 4 hours, take it out and blow it with high-pressure air, dry it in the shade, and then dry it. Compared with the heat storage body without soaking treatment, the matrix density of the pore wall of the heat storage body after soaking treatment is increased by 5.5%, 9% and 10% respectively, and the heat storage body is along the parallel and vertical directions of the honeycomb cells 1 The compressive strength increased by 0.6 times, 0.7 times and 0.9 times respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com