Lubricating liquid for tire dynamic balance test, and preparation method thereof

A technology for lubricating fluid and tires, applied in the direction of lubricating composition, petroleum industry, etc., can solve problems such as not involved in the field of tire dynamic balance testing, tire manufacturers with heavy residual traces, and insufficient lubrication performance, so as to improve the shelf life and prolong the shelf life Excellent effect of time and lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

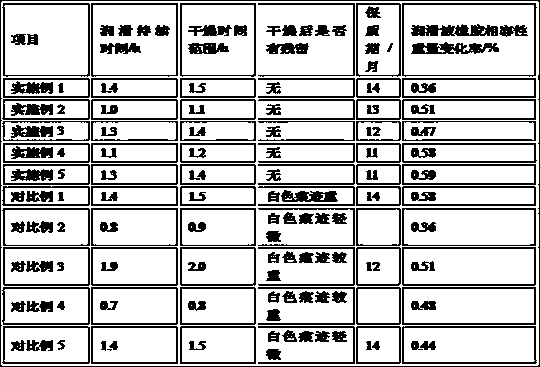

Examples

Embodiment 1

[0029] A tire dynamic balance test lubricant and a preparation method thereof, comprising the following raw materials in parts by weight:

[0030] 10 g of water-soluble polymer (weighed after mixing 1 g of polyoxyalkylene and 15 g of polyacrylamide), 20 g of thickener (16 g of acrylic acid polymer and 4 g of carboxymethyl cellulose), 10 g of surfactant (Weigh after mixing 9 g of polyvinylpyrrolidone and 3 g of hexadecyltrimethylammonium bromide), 3 g of antiseptic and fungicide 1,2-phenylpropylisothiazolinone, and 20 g of leveling agent block polymer , wetting agent N-vinylpyrrolidone 20 g, antioxidant tea polyphenol 0.4 g, deionized water 916.6 g.

[0031] A tire dynamic balance test lubricant and a preparation method thereof, comprising the following steps:

[0032] (1) Mix the water-soluble polymer, surfactant and water under stirring, the mixing temperature is 20°C, and the mixing time is 60 min;

[0033] (2) While stirring, add the thickener to the mixed solution in ste...

Embodiment 2

[0036] A tire dynamic balance test lubricant and a preparation method thereof, comprising the following raw materials in parts by weight:

[0037] 30 g of water-soluble polymer (weighed after mixing 30 g of polyethylene glycol and 3 g of polyacrylamide), 10 g of thickener (8 g of acrylic acid polymer and 2 g of guar gum), 20 g of surfactant (15 g of polyvinylpyrrolidone and 5 g of poloxamer), 3 g of preservative and bactericide 1,2-phenylpropanisothiazolinone, 20 g of leveling agent block polymer, 20 g of wetting agent glycerol, Oxidant 0.3 g (Vc palmitate 0.15 g and tea polyphenols 0.15 g), deionized water 896.7 g.

[0038] A tire dynamic balance test lubricant and a preparation method thereof, comprising the following steps:

[0039] (1) Mix the water-soluble polymer, surfactant and water under stirring, the mixing temperature is 40°C, and the mixing time is 30 minutes;

[0040] (2) While stirring, add the thickener to the mixed solution in step (1), and stir at constant t...

Embodiment 3

[0043] A tire dynamic balance test lubricant and a preparation method thereof, comprising the following raw materials in parts by weight:

[0044] 20 g of water-soluble polymer (weighed after mixing 20 g of polyethylene glycol and 2 g of polyoxyalkylene), 10 g of thickener (8 g of acrylic acid polymer and 2 g of carboxymethyl cellulose), 20 g of surfactant (15 g of polyvinylpyrrolidone and 5 g of alkylphenol polyoxyethylene ether), 5 g of preservative and fungicide 3-iodo-2 propynyl-N-n-butyl carbamate, 30 g of leveling agent block polymer , 10 g of wetting agent glycerin, 0.40 g of antioxidant tea polyphenols, and 904.6 g of deionized water.

[0045] A tire dynamic balance test lubricant and a preparation method thereof, comprising the following steps:

[0046] (1) Mix the water-soluble polymer, surfactant and water under stirring, the mixing temperature is 30°C, and the mixing time is 45 min;

[0047](2) While stirring, add the thickener to the mixed solution in step (1), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com