Composite ternary positive electrode material, preparation method thereof and lithium-ion battery

A cathode material, ternary material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of low discharge platform voltage, and achieve the effect of high discharge platform, high stability and cycle life, and high voltage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

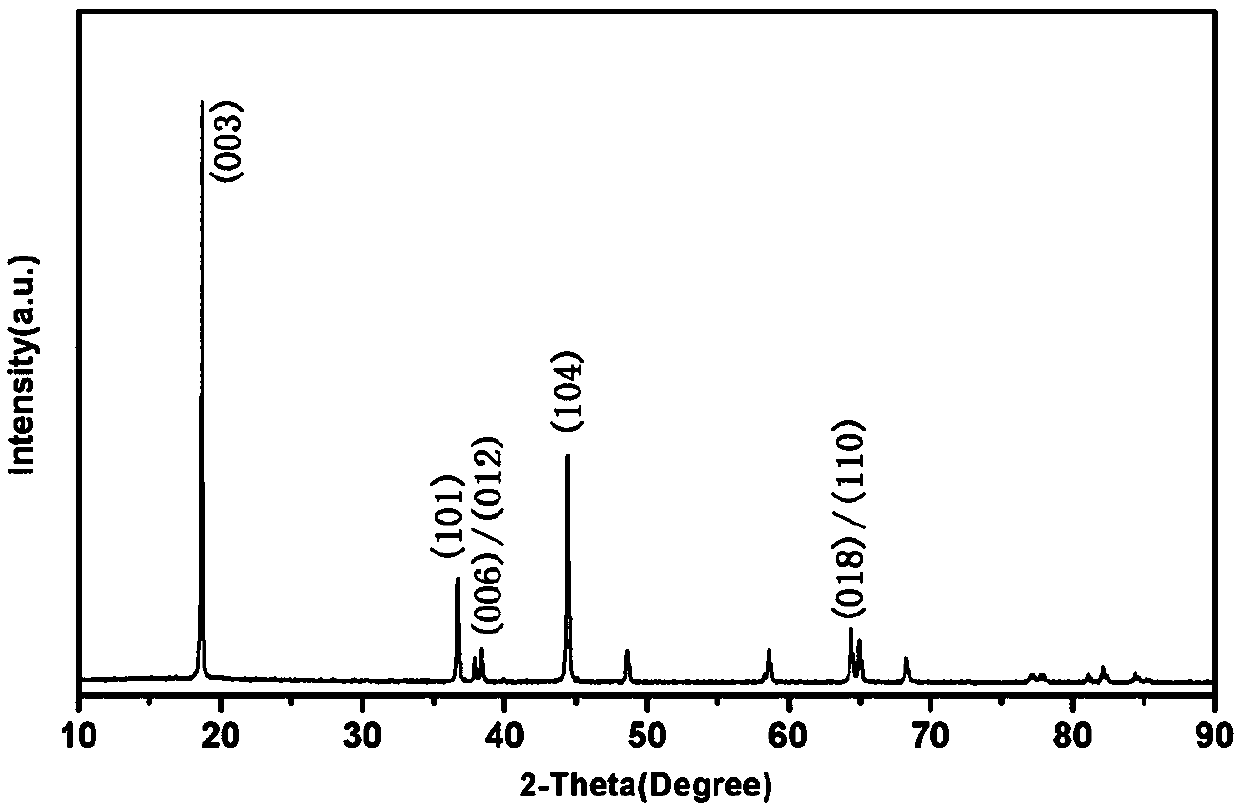

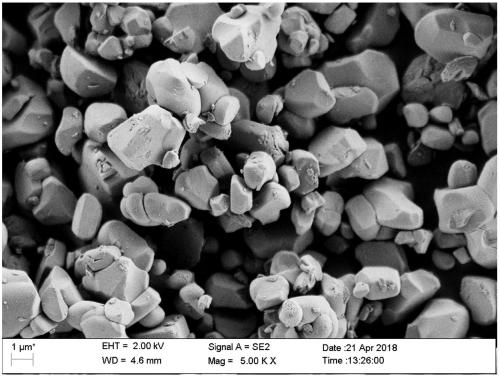

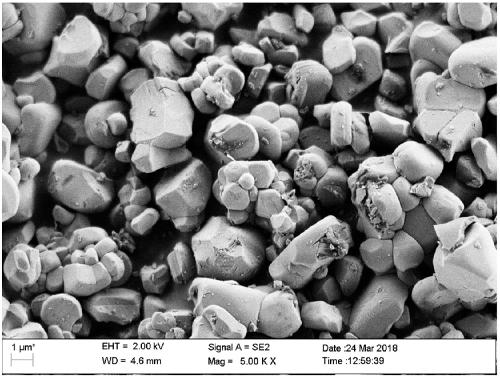

Image

Examples

Embodiment 1

[0031] Embodiment 1 of the preparation method of the composite ternary positive electrode material of the present invention adopts the following steps:

[0032] 1) Primary low-temperature sintering: Mix lithium hydroxide monohydrate and the precursor evenly, the molar amount of Li in lithium hydroxide monohydrate is 1.1 times the sum of the molar amounts of Ni, Co, and Mn in the precursor, and then Sinter in dry air at 700°C for 20 hours, and cool down to room temperature naturally; after sintering, crush it through a 300-mesh sieve to obtain a primary sintered product.

[0033] 2) Secondary high-temperature sintering: mix the primary sintered product and additive KCl evenly, the mass of KCl is 0.1% of the mass of the primary sintered product, then sinter in an atmosphere furnace in dry air at 900°C for 15 hours, and cool down to room temperature naturally ; After the sintering is completed, it is crushed by air flow and passed through a 300-mesh screen to obtain a secondary s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com