Wet oxidation catalyst and preparation method and application thereof

A wet oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of poor catalytic activity, difficult operation and high energy consumption , to achieve the effect of easy operation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

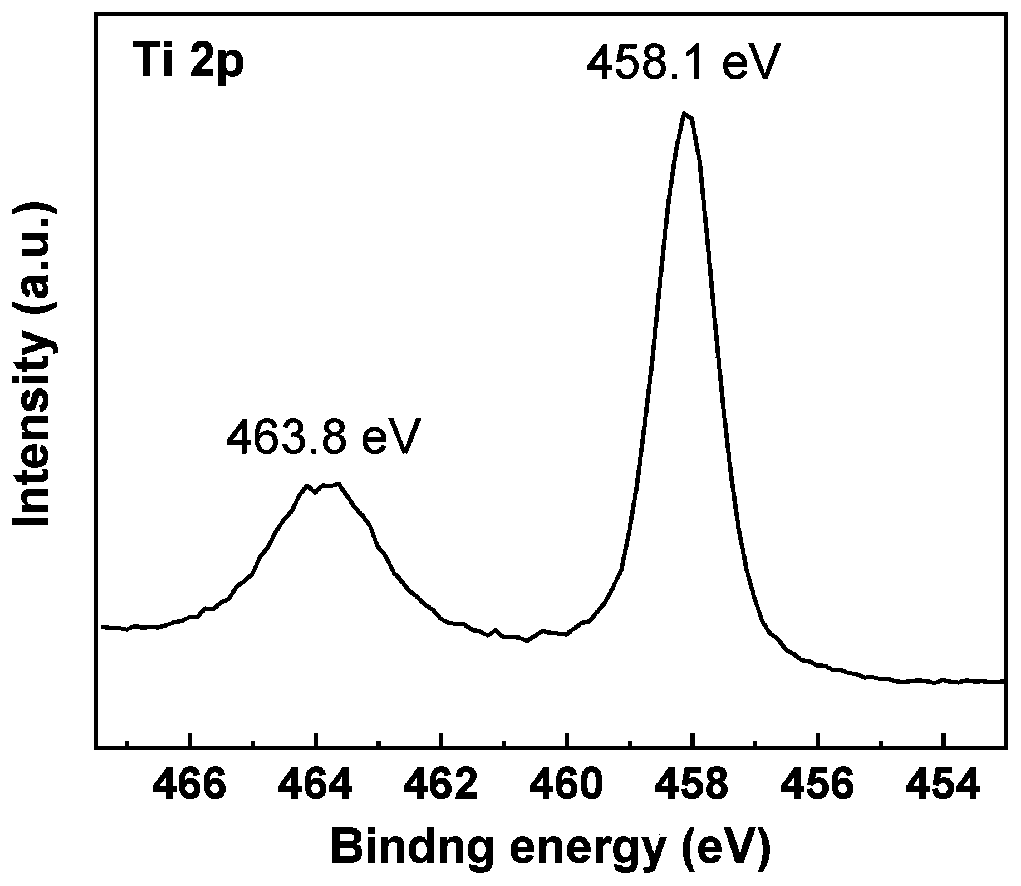

[0068] (1) TiO 2 Put it into a round bottom flask, add ruthenium chloride aqueous solution, then add 5mL deionized water, stir well to make it disperse evenly; control TiO 2 The dosage is 0.5g, and the dosage of ruthenium chloride is 10mg, so that the mass ratio of the noble metal active component and the carrier in the final catalyst is 1:99.

[0069] (2) Rotary evaporator evaporates water, and then dries the evaporated matter in an oven to obtain a catalyst precursor.

[0070] (3) Carry out the first reduction of the catalyst precursor in a hydrogen atmosphere, then roast in methane successively in nitrogen, and finally carry out the second reduction in a hydrogen atmosphere, wherein the temperature of the first reduction is 400 ° C, and the time is 4h, The temperature of roasting in methane is 500° C. for 2 hours, the temperature of roasting in nitrogen is 500° C. for 2 hours, and the temperature of second reduction is 400° C. for 4 hours. After the second reduction is co...

Embodiment 2~4

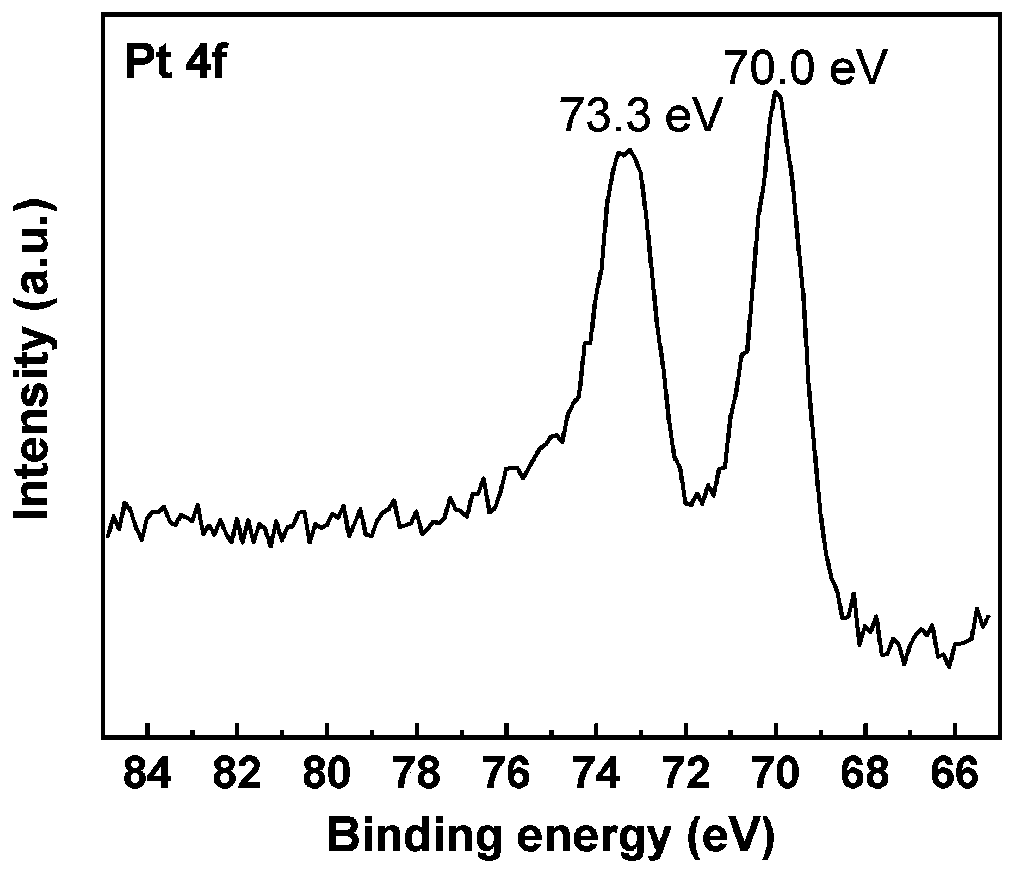

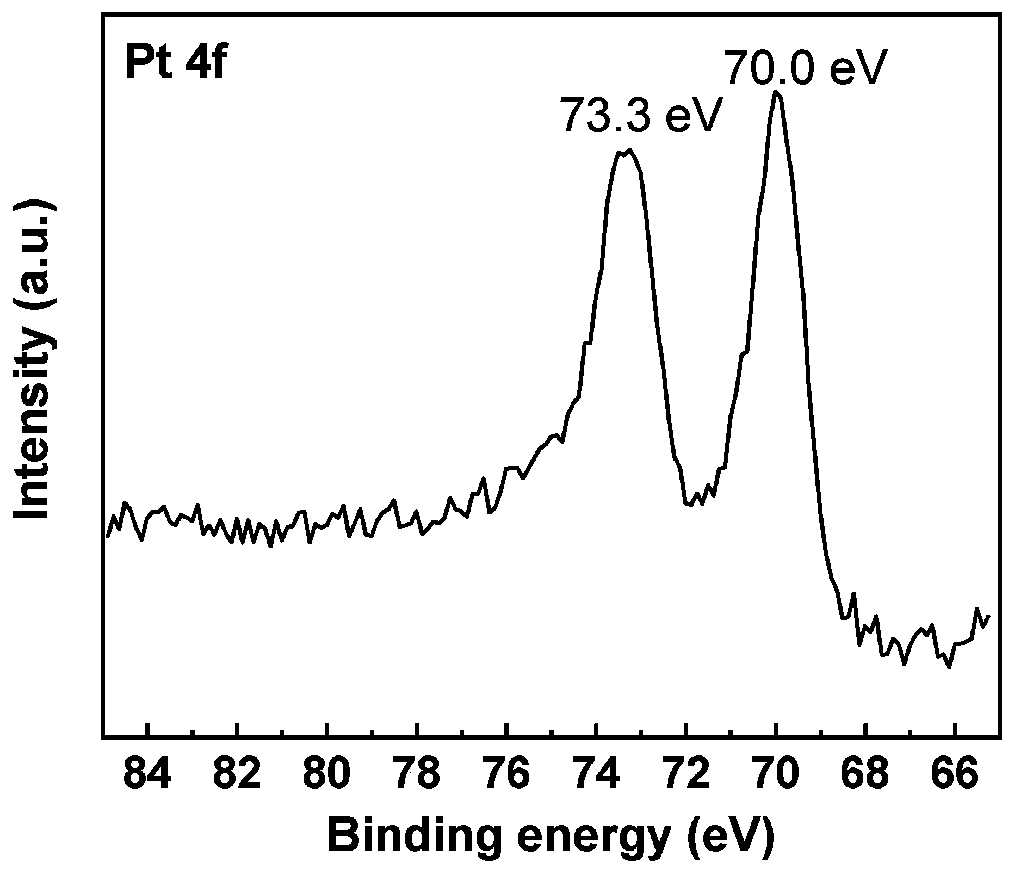

[0072] Other steps are the same as in Example 1, only the ruthenium chloride aqueous solution is replaced by rhodium chloride aqueous solution, palladium chloride aqueous solution and chloroplatinic acid aqueous solution respectively, and the gained catalyst is successively recorded as Rh-TiO 2 -impregnation, Pd-TiO 2 -impregnation and Pt-TiO 2 -impregnation.

Embodiment 5

[0074] (1) 0.05 g of ruthenium acetylacetonate, 18 ml of oleylamine and 0.2 g of borane-tert-butylamine were mixed, and reacted at 150° C. for 2 hours to obtain ruthenium nanoparticles.

[0075] (2) TiO 2 Dissolve in toluene, add ruthenium nanoparticles, centrifuge and dry after fully stirring to obtain a catalyst precursor, in which TiO 2 The mass ratio to ruthenium nanoparticles is 1:99.

[0076] (3) Carry out the first reduction of the catalyst precursor in a hydrogen atmosphere, then roast in methane successively in nitrogen, and finally carry out the second reduction in a hydrogen atmosphere, wherein the temperature of the first reduction is 400 ° C, and the time is 4h, The temperature for roasting in methane is 300° C. for 4 hours, the temperature for roasting in nitrogen is 300° C. for 4 hours, and the temperature for the second reduction is 400° C. for 4 hours. After the second reduction is completed, the wet oxidation catalyst is obtained, which is Ru-TiO 2 -oil (o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com