Preparation method and applications of PtCu monatomic alloy nano-catalyst

A technology of alloy nanoparticles and alloy nanoparticles, which is applied in the field of preparation of PtCu single-atom alloy nanocatalysts, can solve the problems of easy agglomeration structure of Cu, low Pt loading, and change, and achieve broad application prospects, good stability, and copper dispersion high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

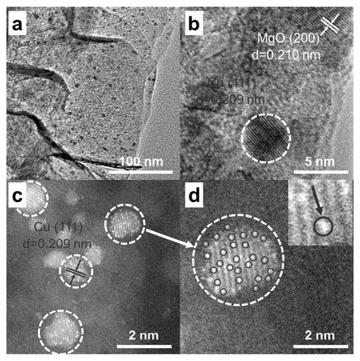

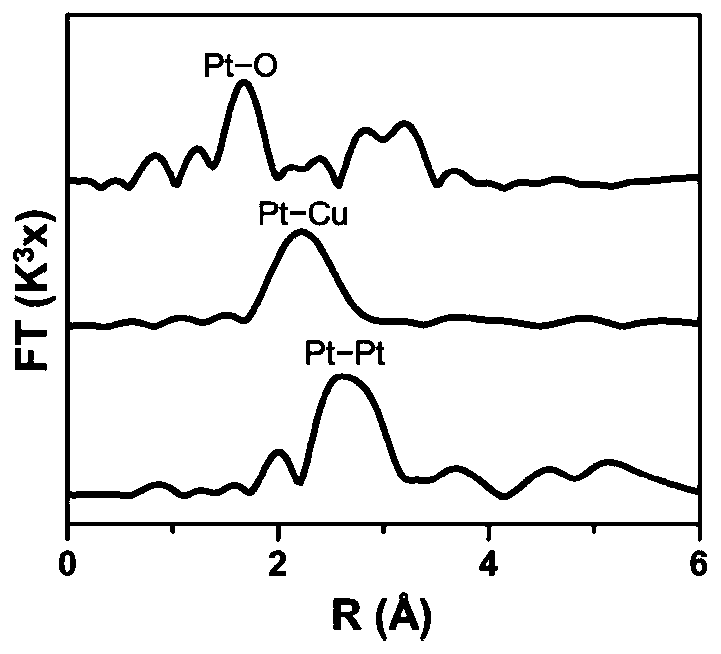

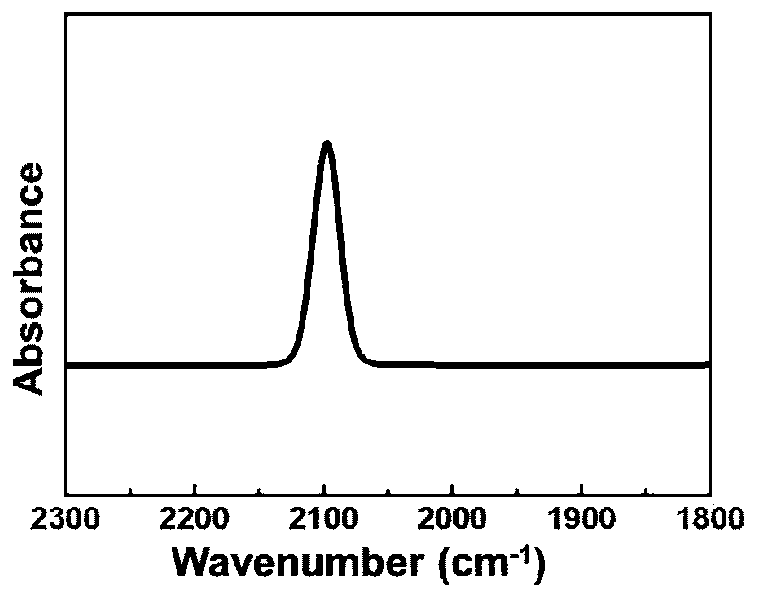

Embodiment 1

[0020] Prepare a mixed solution of copper nitrate (0.15 g), magnesium nitrate (3.0 g), aluminum nitrate (2.5 g) and urea (8.5 g) with 150.0 g of deionized water, and stir until completely dissolved. The above-prepared solution was transferred to a stainless steel hydrothermal reaction kettle, and then crystallized at 110° C. for 24 hours. The product was washed with deionized water until neutral, and dried in a vacuum oven at 60°C for 8 hours to obtain the CuMgAl-LDHs precursor. The obtained CuMgAl-LDHs precursor was calcined in an air atmosphere in a muffle furnace, the temperature was raised to 500 °C at 5 °C / min and kept for 4 h; the temperature was lowered to room temperature at 10 °C / min to obtain the corresponding Cu / MMO catalyst. Place 0.30 g of Cu / MMO catalyst in 50 ml of deionized water, and add H to it dropwise under nitrogen atmosphere. 2 PtCl 4 Aqueous solution (8.0mM) 0.7mL, ultrasonic 10min in ice-water bath. The obtained product was washed twice with deionize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com