Catalyst, preparation method and application of acetophenone hydrogenation to prepare α-phenylethanol

A hydrogenation catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc. Low conversion rate of ketones and other problems, to achieve the effect of improving catalyst activity and selectivity, improving catalyst activity, and smoothing catalyst pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

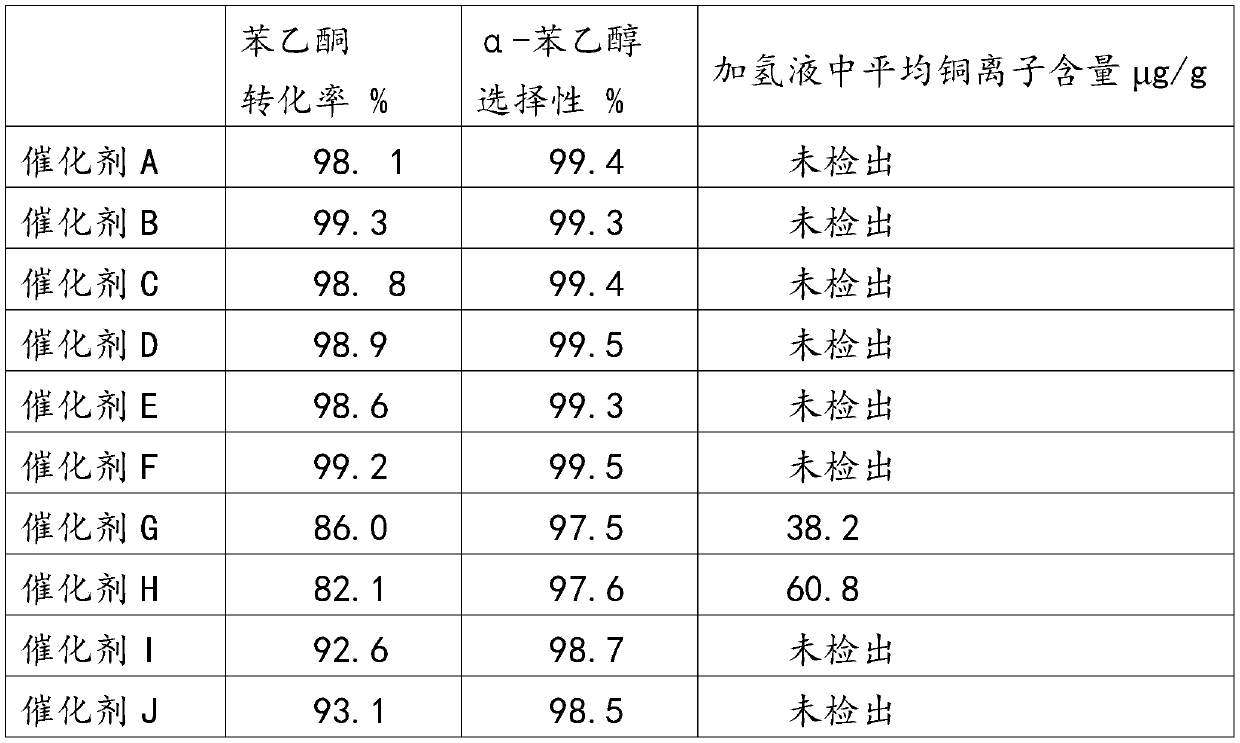

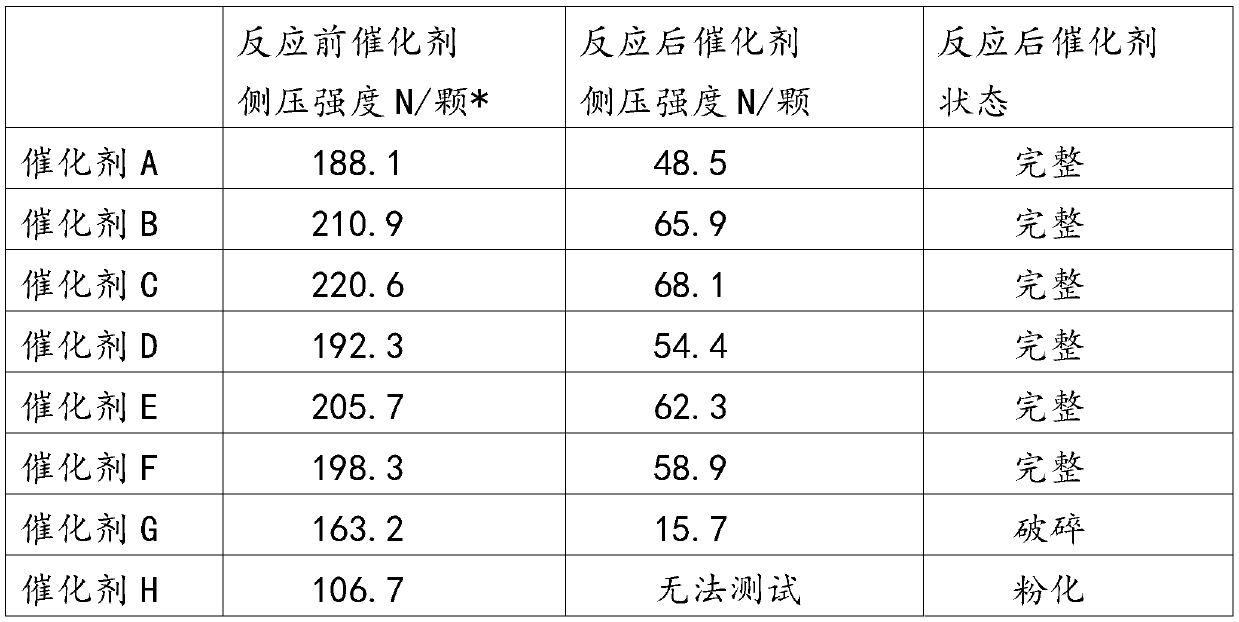

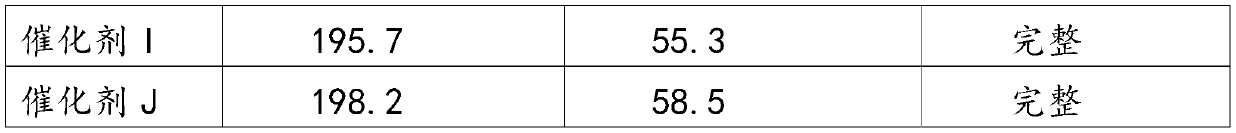

Examples

Embodiment 1

[0045] Add 200g of water, 10g of methanol, 4.0g of PMMA with a particle size of 10-30μm, and 2.0g of C 16-6-16 The Gemini surfactant (purchased from Henan Dao Pure Chemical Co., Ltd.) was mixed evenly, and then 120.0 g of 30% concentration of silica sol was added and stirred evenly. Dissolve 332.2g of copper nitrate, 73.1g of zinc nitrate, 21.3g of lanthanum nitrate, and 12.7g of magnesium nitrate in 1.5kg of water to make a mixed salt solution, and dissolve 113.5g of sodium silicate and 142.5g of sodium carbonate in water to make a precipitant solution , respectively, the two solutions were heated to 70 ℃. The method of co-precipitation was adopted, and the two solutions were dropped into the reactor at the same time, and the temperature in the reactor was controlled to be 70° C., the pH of the system to be 7.0, and the reaction time to be 1 h during the precipitation process. After the two solutions are added dropwise, use 10wt% sodium carbonate solution to adjust the pH va...

Embodiment 2

[0049] Add 200g of water, 15g of ethanol, 6.0g of microcrystalline cellulose with a particle size of 5-30μm, and 0.5g of C 12-10-12 Gemini surfactant (purchased from Henan Dao Pure Chemical Co., Ltd.), then add 61.3g of 30% concentration of silica sol, and stir evenly. Dissolve 362.4g of copper nitrate, 87.7g of zinc nitrate, 22.7g of cerium nitrate, and 4.21g of calcium nitrate in 1.45kg of water to make a mixed salt solution, and dissolve 130.5g of sodium silicate and 149.0g of sodium carbonate in water to make a precipitant solution , respectively, the two solutions were heated to 75 ℃. The method of co-precipitation was adopted, and the two solutions were dropped into the reactor at the same time, and the temperature in the reactor was controlled to be 75° C., the pH of the system was 7.2, and the reaction time was 1 h during the precipitation process. After the two solutions are added dropwise, use 10wt% sodium carbonate solution to adjust the pH value of the system to >...

Embodiment 3

[0052] Add 200g of water, 10g of propanol, 10.0g of methylcellulose with a particle size of 5-20μm, and 1.0g of C 14-8-14 Gemini surfactant (purchased from Henan Dao Pure Chemical Co., Ltd.) was mixed evenly, then 116.7g of 30% concentration of silica sol was added and stirred evenly. 302g of copper nitrate, 87.7g of zinc nitrate, 5.0g of cerium nitrate, and 6.8g of barium nitrate were dissolved in 1.37kg of water to form a mixed salt solution, and 198.7g of sodium silicate and 93.6g of sodium carbonate were dissolved in water to form a precipitant solution. The two solutions were heated to 80°C separately. The method of co-precipitation was adopted, and the two solutions were dropped into the reactor at the same time, and the temperature in the reactor was controlled to be 80° C., the pH of the system was 8.0, and the reaction time was 1 h during the precipitation process. After the two solutions are added dropwise, use 10wt% sodium carbonate solution to adjust the pH value ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com