Composite nano-material with nano-particles wrapped by meso-porous silica, and preparation method and application thereof

A technology of composite nanomaterials and mesoporous silica, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as cumbersome steps, limited materials, and large fluctuation range. Achieve the effect of simple process and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

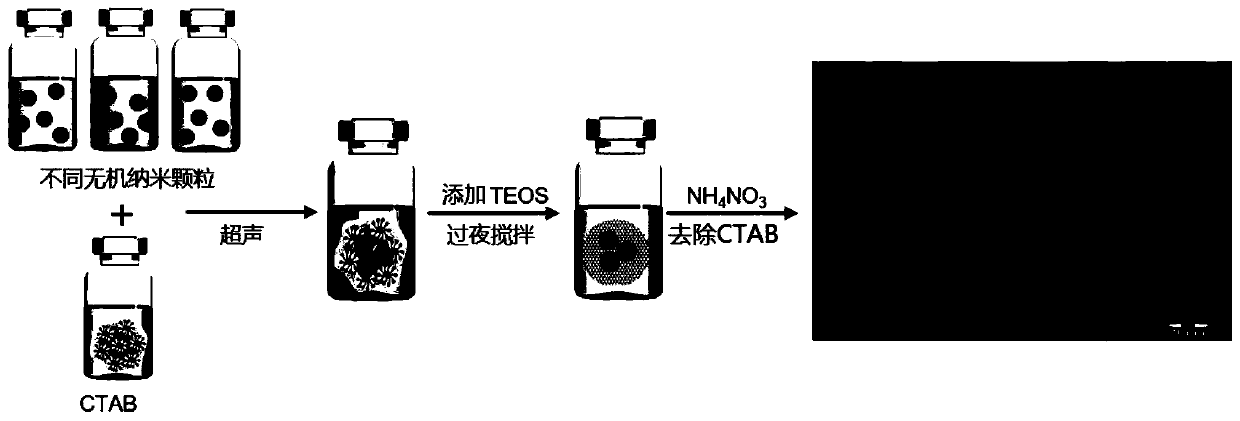

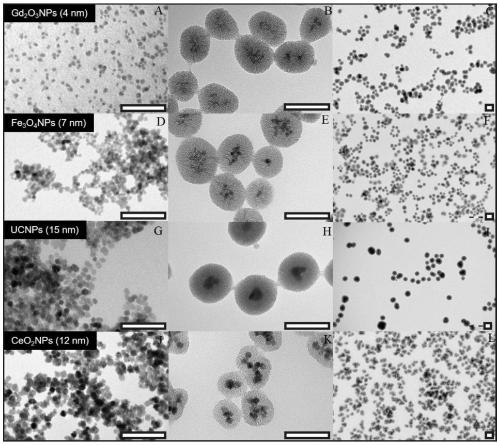

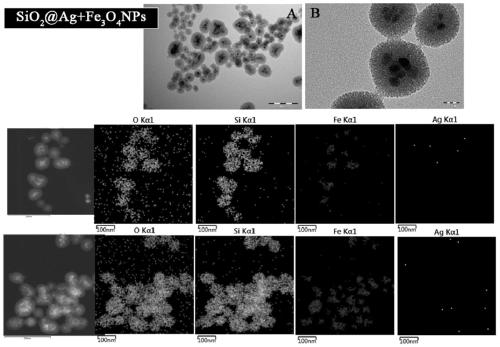

[0041] This embodiment is an embodiment of the method for preparing a composite nanomaterial using mesoporous silica to wrap nanoparticles in the present invention. The preparation method includes the following steps:

[0042] (1) Gd with a particle size of 4nm 2 o 3 NPs (the TEM images of which are shown in figure 2 Shown in A) is dispersed in ethanol aqueous solution (the volume ratio of ethanol and water is ethanol: water=1:4), then adds ammonia water, keeps stirring for 30min, obtains the solution a that pH value is 10 (according to the size calculation of nanoparticle Specific surface area, in order to make the ratio of the mass of CTAB and the specific surface area of nanoparticles be 3mg:10 17 nm 2 , Gd in solution a 2 o 3 NPs concentration was 0.5mg / mL); CTAB was added to the same aqueous ethanol solution and kept stirring for 30min to obtain a solution b with a CTAB concentration of 30mg / mL;

[0043] (2) Add solution b dropwise to solution a (the volume ratio...

Embodiment 2

[0046] This embodiment is an embodiment of the method for preparing a composite nanomaterial using mesoporous silica to wrap nanoparticles in the present invention. The preparation method includes the following steps:

[0047] (1) Fe with a particle size of 7nm 3 o 4 NPs (the TEM images of which are shown in figure 2 Shown in D) is dispersed in ethanol aqueous solution (the volume ratio of ethanol and water is ethanol: water=1:4), adds ammoniacal liquor, keeps stirring 30min, obtains the solution a that pH value is 10 (according to the size calculation of nanoparticle Specific surface area, for making the ratio of the mass of CTAB and the specific surface area of nanoparticle be 3mg:10 17 nm 2 , Fe in solution a 3 o 4 NPs concentration was 0.6mg / mL); CTAB was added to the same aqueous ethanol solution and kept stirring for 30min to obtain a solution b with a CTAB concentration of 30mg / mL;

[0048] (2) Add solution b dropwise to solution a (the volume ratio of solution...

Embodiment 3

[0051] This embodiment is an embodiment of the method for preparing a composite nanomaterial using mesoporous silica to wrap nanoparticles in the present invention. The preparation method includes the following steps:

[0052] (1) UCNPs with a particle size of 15nm (ie Tm 3+ Co-doped NaYF 4 Nanocrystalline, Tm 3+ upconversionnanophosphors, whose TEM images are shown in figure 2 Shown in G) is dispersed in ethanol aqueous solution (the volume ratio of ethanol and water is ethanol: water=1:4), then adds ammoniacal liquor, keeps stirring 30min, obtains the solution a that pH value is 10 (according to the size calculation of nanoparticle Specific surface area, for making the ratio of the mass of CTAB and the specific surface area of nanoparticle be 3mg:10 17 nm 2 , the concentration of UCNPs in solution a is 1.5mg / mL); CTAB is added in the same ethanol aqueous solution, keep stirring for 30min, obtain the solution b that CTAB concentration is 30mg / mL;

[0053] (2) Add sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com