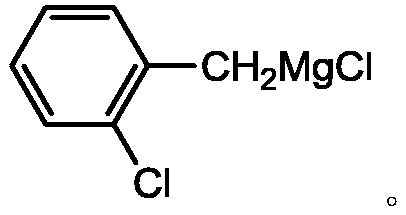

Continuous preparation method of o-chlorobenzyl chloride Grignard reagent

A technology of o-chlorobenzyl-Grignard and benzyl-chloro-Grigner, which is applied in the field of continuous preparation of o-chlorobenzyl-Grignard reagents, and can solve the problems of energy accumulation, large liquid holding capacity, and volume reduction, etc. , to achieve the effect of reducing side reactions, small liquid holding capacity of equipment, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

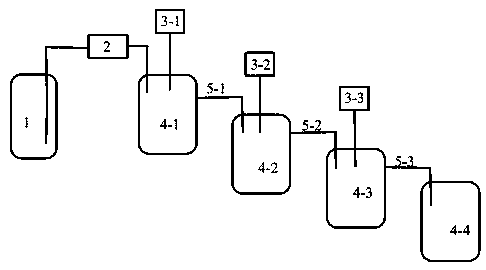

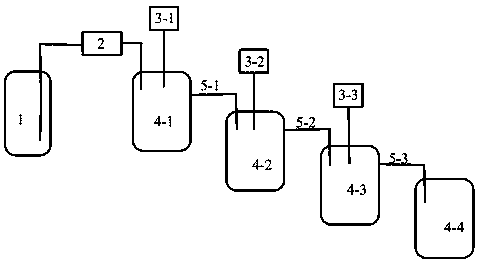

[0030] A kind of continuous method for preparing the Grignard reagent of o-chlorobenzyl chloride, concrete steps are as follows: (3 reactors are connected in series)

[0031] Raw material preparation: add 700g of o-chlorobenzyl chloride and 2100g of ethylene glycol dimethyl ether into the raw material kettle, and mix well; add 100g and 25g of magnesium chips into the solid feeders of the two forward reaction kettles respectively for later use.

[0032]Carry out nitrogen flow purging to the whole reaction series system, and continue to pass nitrogen flow, add the ethylene glycol of ortho-chlorobenzyl chloride to the first reaction kettle (the reaction kettles are all 1000ml, and the effective volume to the overflow port is about 800ml). 100g of dimethyl ether solution (10g of o-chlorobenzyl chloride and 90g of ethylene glycol dimethyl ether), add 5g of magnesium chips, add 3 grains of iodine, and turn on the temperature control system so that the temperature of the first kettle ...

Embodiment 2

[0034] A kind of continuous method for preparing the Grignard reagent of o-chlorobenzyl chloride, concrete steps are as follows: (3 reactors are connected in series)

[0035] Raw material preparation: add 500g of o-chlorobenzyl chloride, 2000g of toluene, and 400g of tetrahydrofuran into the raw material kettle, and mix evenly; add 70g and 20g of magnesium chips into the solid feeders of the first two reaction kettles respectively for later use.

[0036] The whole reaction series system is purged with nitrogen flow, and the nitrogen flow is continued, and the toluene / tetrahydrofuran of o-chlorobenzyl chloride is added to the first reaction kettle (the reaction kettles are all 1000ml, and the effective volume to the overflow port is about 800ml). Solution 100g (wherein o-chlorobenzyl chloride is 10g, toluene is 75g, tetrahydrofuran 15g), adds 5g of magnesium chips, adds 3 grains of iodine, turns on the temperature control system, makes the temperature of the first still be 40 ℃,...

Embodiment 3

[0038] A kind of continuous method for preparing the Grignard reagent of o-chlorobenzyl chloride, concrete steps are as follows: (4 reaction kettles are connected in series)

[0039] Raw material preparation: add 1000g of o-chlorobenzyl chloride and 3000g of methyl tert-butyl ether into the raw material kettle, and mix well; add 125g, 45g and 15g of magnesium chips into the solid feeders of the three forward reaction kettles for later use.

[0040] The whole reaction series system is purged with nitrogen flow, and the nitrogen flow is continued, and in the first reaction kettle (the reaction kettles are all 1000ml, and the effective volume to the overflow port is about 800ml), the methyl tertiary methyl chloride of o-chlorobenzyl chloride is added. 100g of butyl ether solution (of which 10g of o-chlorobenzyl chloride and 90g of methyl tert-butyl ether), add 5g of magnesium chips, add 3 grains of iodine, and turn on the temperature control system so that the temperature of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com