Low-dielectric-constant liquid crystal polymer and preparation method thereof

A technology of liquid crystal polymer and low dielectric constant, which is applied in the field of low dielectric constant liquid crystal polymer and its preparation, can solve the problems of affecting signal propagation speed and large dielectric constant, and achieve less equipment and low dielectric constant performance and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

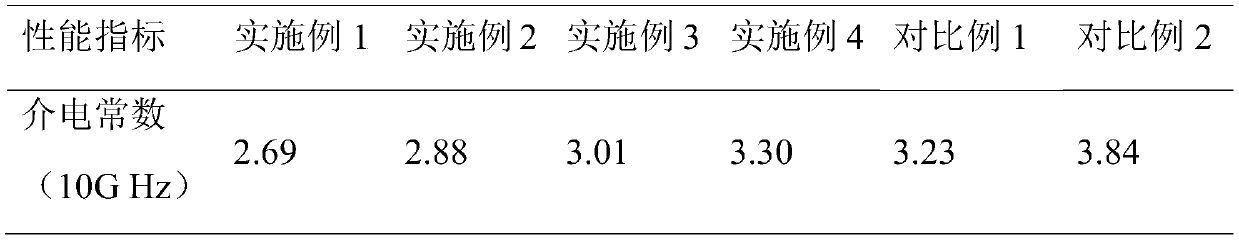

Examples

preparation example Construction

[0056] Preferably, the preparation method of the wholly aromatic liquid crystal polyester resin comprises the steps of:

[0057] S011. Provide at least 2 kinds of monomer substances, and perform polycondensation reaction to prepare a wholly aromatic liquid crystal polyester prepolymer;

[0058] S012. Performing a solid-state polycondensation reaction on the wholly aromatic liquid crystal polyester prepolymer to prepare the wholly aromatic liquid crystal polyester resin.

[0059] In the above step S011, the monomer substance is selected from at least two kinds of free aromatic diol, aromatic diamine, aromatic hydroxylamine, aromatic dicarboxylic acid, aromatic hydroxycarboxylic acid and aromatic aminocarboxylic acid. Since the whole aromatic liquid crystal polyester resin is composed of the monomers, the prepared whole aromatic liquid crystal polyester resin has better performance, so that the low dielectric constant liquid crystal polymer has more excellent resistance Thermal...

Embodiment 1

[0075] A low dielectric constant liquid crystal polymer

[0076] The low dielectric constant liquid crystal polymer includes, for example, 75 parts of wholly aromatic liquid crystal polyester resin; 25 parts of hollow glass microspheres; wherein, the diameter of the hollow glass microspheres is 20 μm, and the type is 3M iM16K.

[0077] The preparation method of the low dielectric constant liquid crystal polymer, the preparation method includes the following steps: weighing each component according to the low dielectric constant liquid crystal polymer; The hollow glass microspheres were dried at 130° C. for 4 hours; the dried fully aromatic liquid crystal polyester resin and the hollow glass microspheres were put into an automatic mixer and mixed uniformly to obtain a first mixture; The first mixture is put into a twin-screw extruder for melting and kneading, and then extruded, drawn, cooled and granulated to produce the low dielectric constant liquid crystal polymer.

Embodiment 2

[0079] A low dielectric constant liquid crystal polymer

[0080] The low dielectric constant liquid crystal polymer includes, for example, 85 parts of wholly aromatic liquid crystal polyester resin; 15 parts of hollow glass microspheres; wherein, the diameter of the hollow glass microspheres is 20 μm, and the type is 3M iM16K.

[0081] The preparation method of the low dielectric constant liquid crystal polymer, the preparation method includes the following steps: weighing each component according to the low dielectric constant liquid crystal polymer; The hollow glass microspheres were dried at 130° C. for 4 hours; the dried fully aromatic liquid crystal polyester resin and the hollow glass microspheres were put into an automatic mixer and mixed uniformly to obtain a first mixture; The first mixture is put into a twin-screw extruder for melting and kneading, and then extruded, drawn, cooled and granulated to produce the low dielectric constant liquid crystal polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Dielectric constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com