Integrated ultramicro electrode, preparation method thereof and application

An ultra-micro electrode and electrode technology, applied in the direction of electrochemical variables of materials, material analysis by electromagnetic means, measurement devices, etc., can solve the problems of limiting test time, slow change of concentration, etc., to enhance spatial resolution and reduce sample size. The effect of simple consumption, preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail below in conjunction with accompanying drawing:

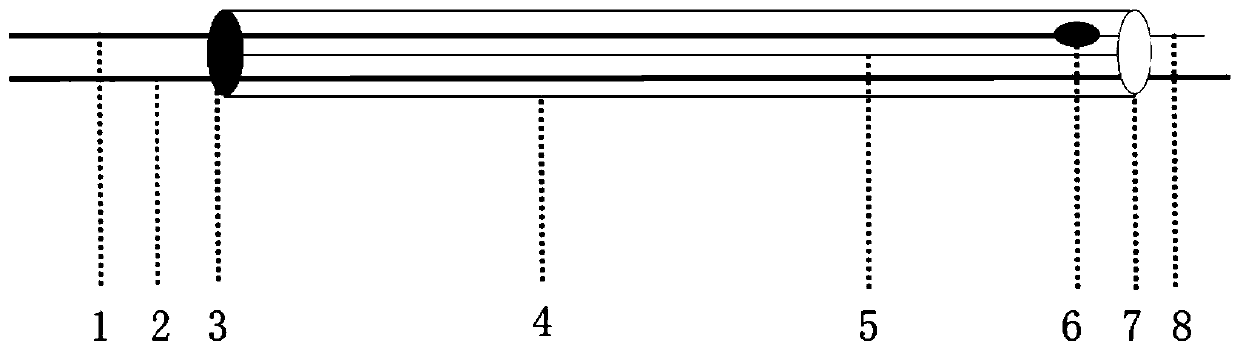

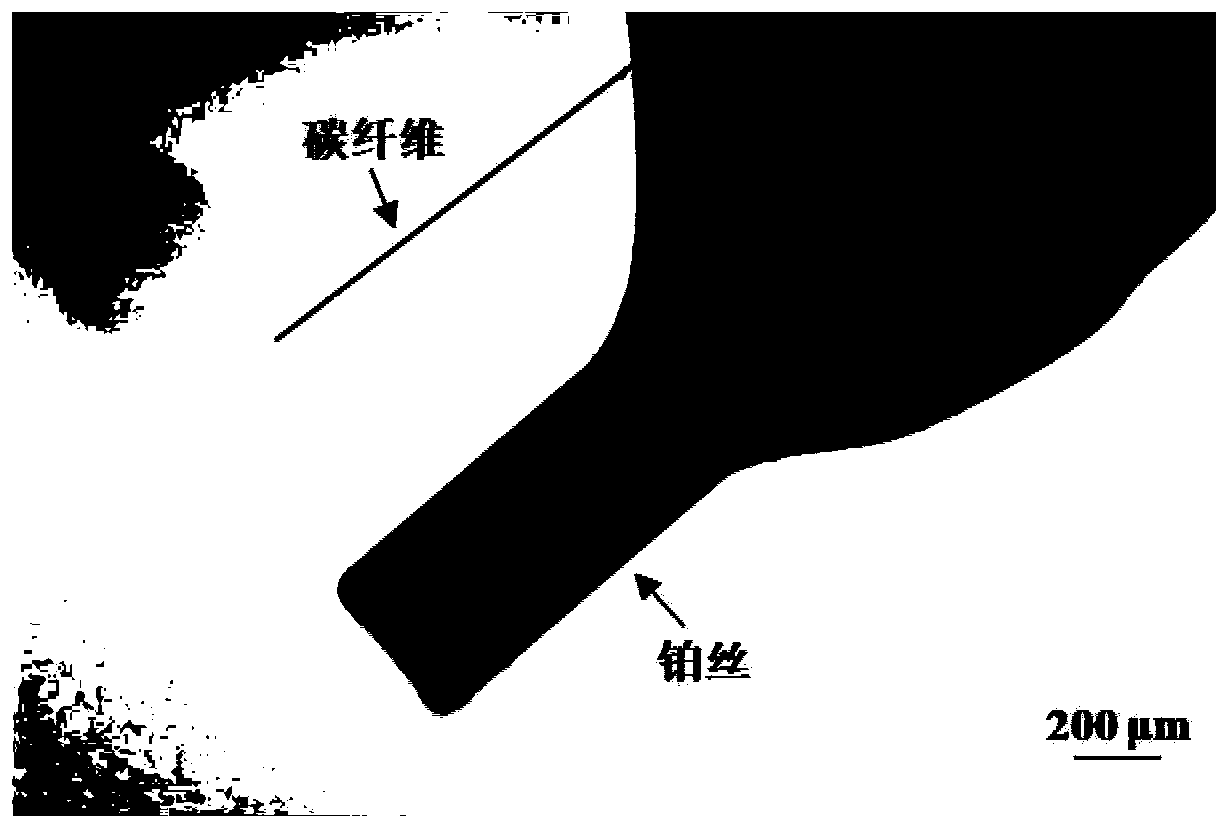

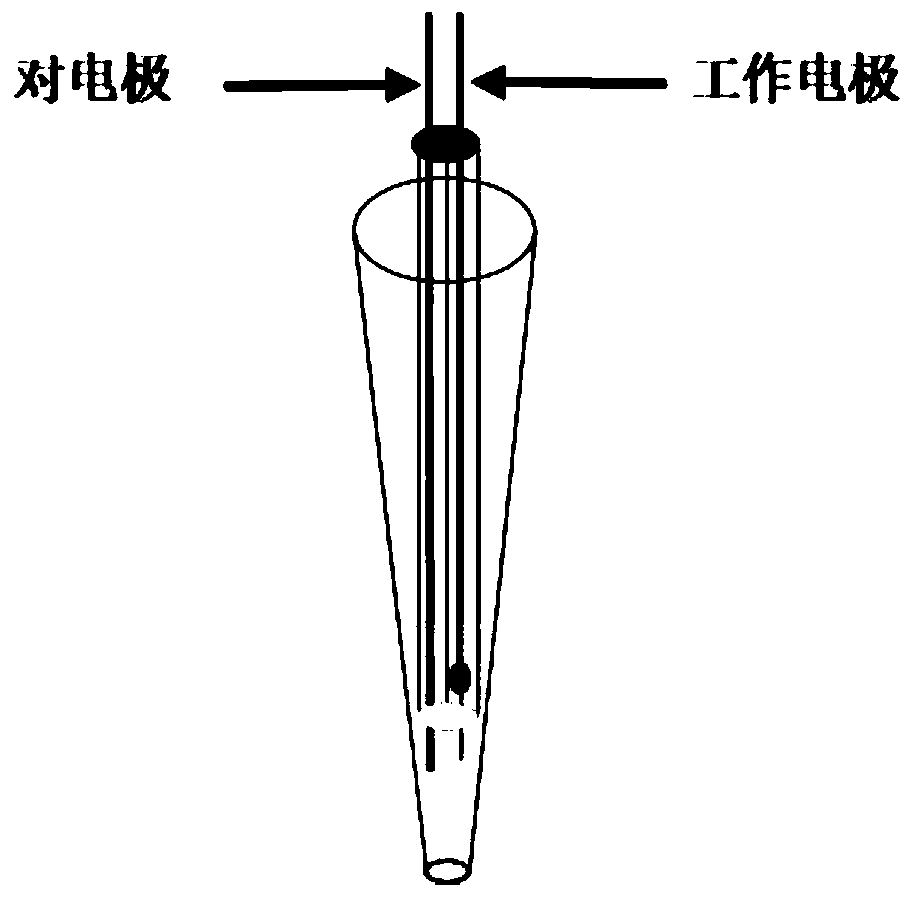

[0031] Such as Figure 1 to Figure 3 As shown, an integrated ultra-microelectrode includes a θ-shaped glass microtube 4, and the θ-shaped glass microtube 4 is provided with a glass diaphragm 5 along the axial direction so that the θ-shaped glass microtube 4 forms two cavities, and the two cavities A counter electrode 2 and a working electrode 1 are respectively arranged inside, the two ends of the θ-shaped glass microtube 4 are sealed, the counter electrode 2 and the working electrode 1 at one end of the θ-shaped glass microtube 4 are connected to the testing instrument, and the other end of the θ-shaped glass microtube 4 The counter electrode 2 and the working electrode 1 protrude from the end face of the θ-shaped glass microtube 4 as the detection contact end.

[0032] The counter electrode 2 is a platinum wire electrode, and the protruding length at the detection c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com