Phase change memory unit and preparation method thereof

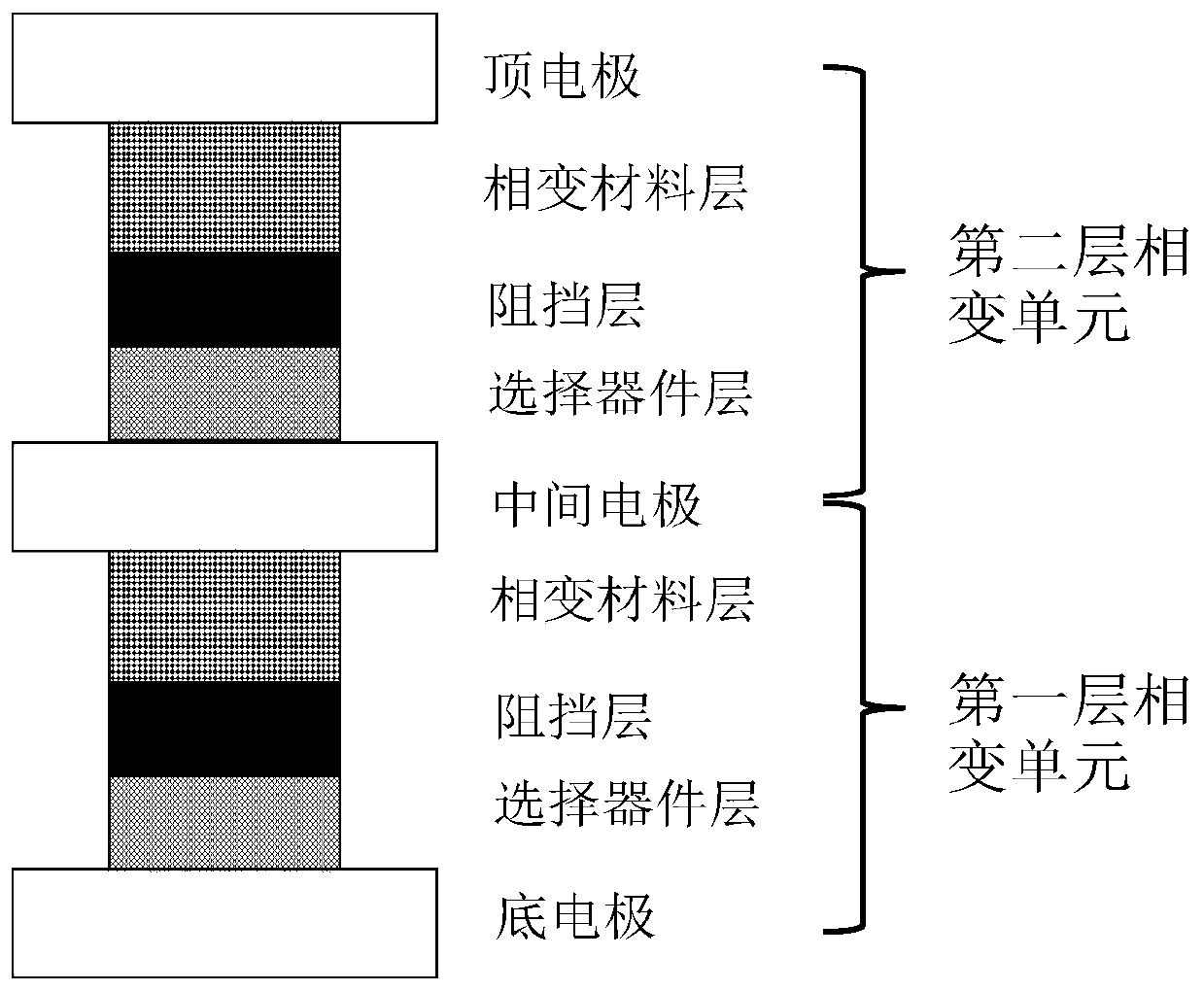

A phase-change memory and phase-change unit technology, applied in electrical components, semiconductor devices, electric solid-state devices, etc., can solve problems such as limited thermal budget, impact on device performance and yield, etc., to reduce device power consumption and achieve high density. The effect of storing and reducing the volume of the phase change operating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

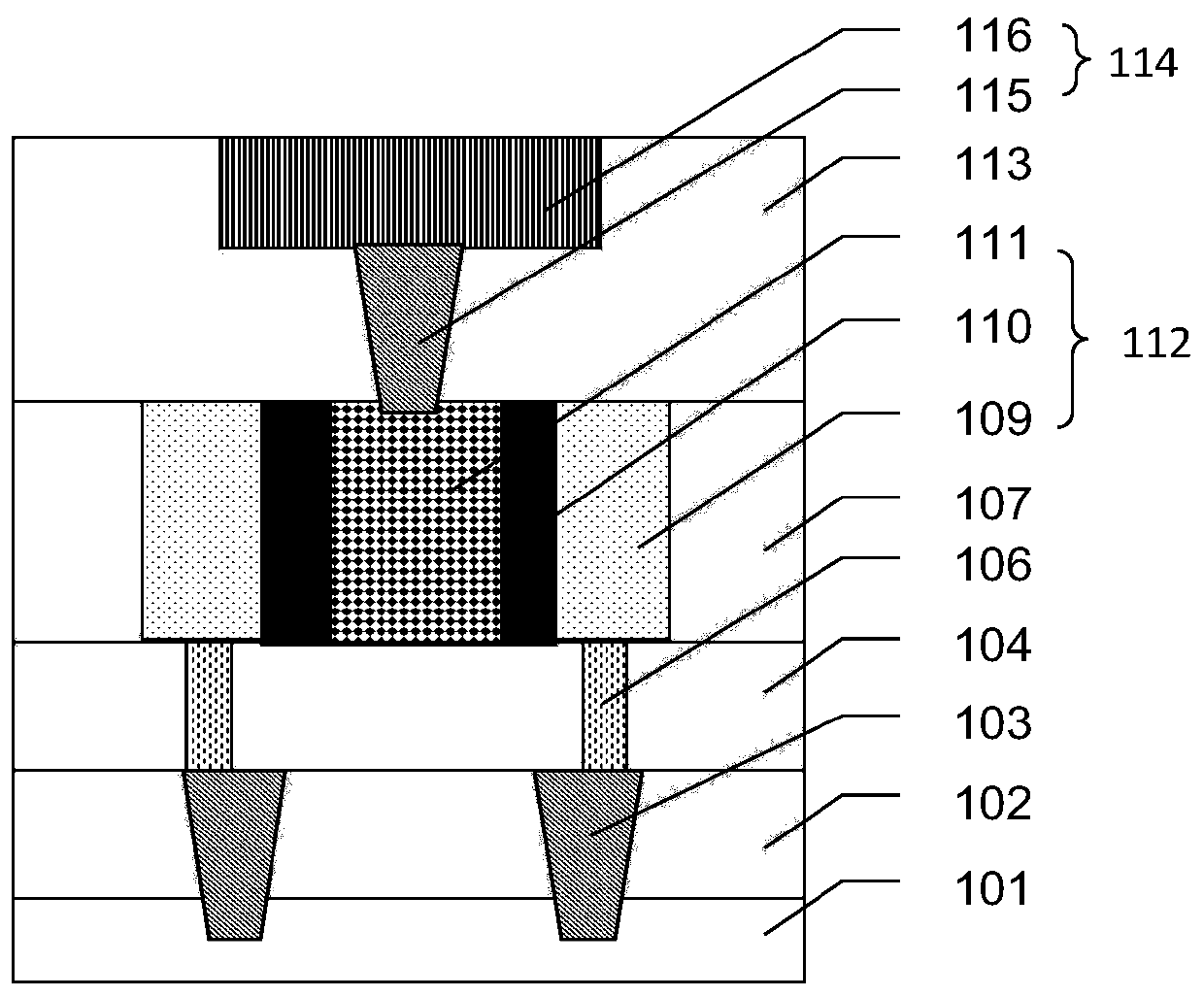

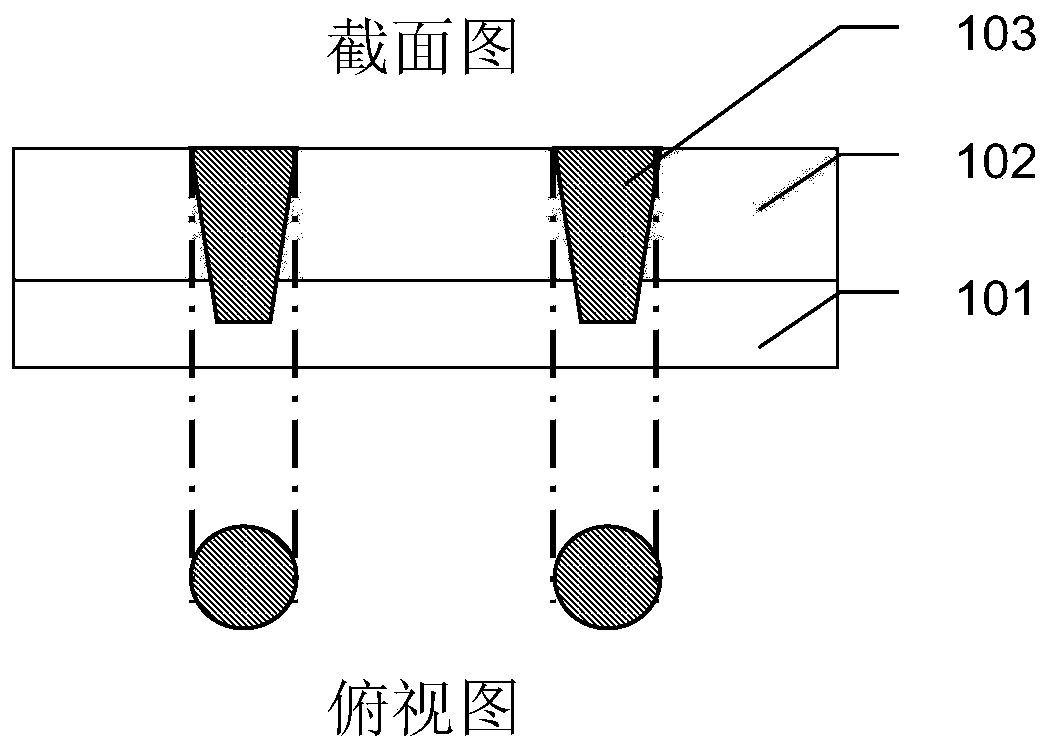

[0050] Please refer to Figure 3-Figure 9 , Figure 3-Figure 9 is prepared figure 2 A schematic diagram of the process steps of a phase-change memory cell structure. like Figure 3-Figure 9 As shown, a preparation method of a phase-change memory unit of the present invention may include the following steps:

[0051] S11: If image 3 As shown, in order to clearly reflect the structure of the present invention, the upper figure in the figure shows a cross-sectional view, and the lower figure shows a top view (the same below), the first dielectric layer 102 is deposited on the substrate 101, and the substrate 101 and the first dielectric layer Two through-hole bottom electrodes 103 are formed in 102 .

[0052] Wherein, the lower half of the bottom electrode 103 can be located in the substrate 101 , and the upper half can be located in the first dielectric layer 102 . In this embodiment, the bottom electrode 103 may be a tungsten electrode through hole with a diameter of 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com