Method for cultivating edible fungi by using edible fungus cultivation bottle

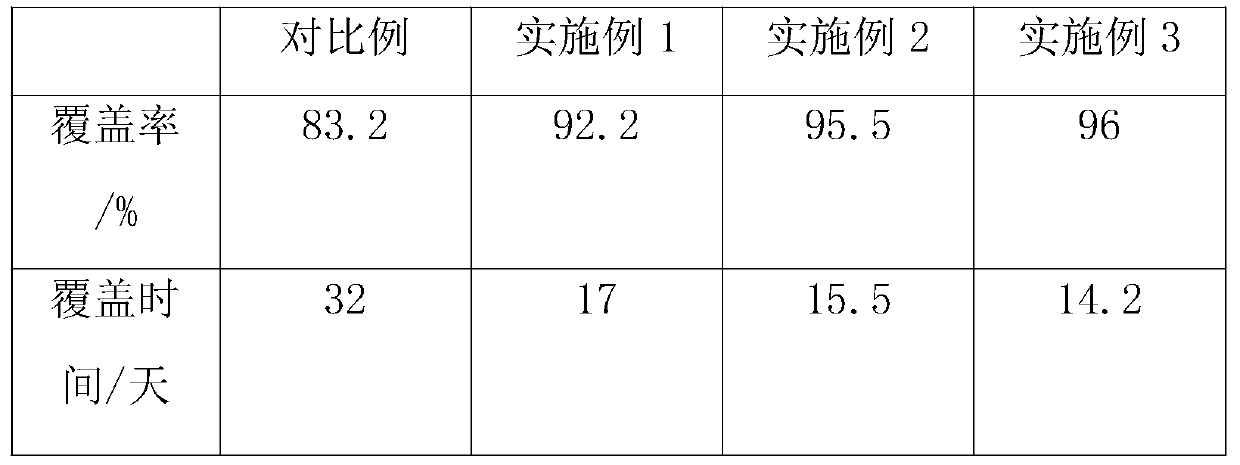

An edible fungus and cultivation bottle technology, which is applied in cultivation, plant cultivation, mushroom cultivation and other directions, can solve the problems of long cultivation time, low coverage rate of mycelium, and incomplete use of nutrients in the culture material, and achieves coverage improvement and shortening. The effect of incubation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Prepare the culture bottle and related equipment: place the culture bottle and related culture equipment in the water basin, and use a brush to clean them thoroughly. After the culture bottle and related equipment are basically cleaned, place them one by one in the mobile Rinse them twice in distilled water, and place the rinsed related instruments on the top of the workbench to dry;

[0032] Step 2: The configuration of the relevant culture material: use 50 parts of sawdust, 50 parts of distiller’s grains, 10 parts of bagasse, 80 parts of corn cob, 50 parts of chaff, 50 parts of peanut hulls and 60 parts of cotton seed hulls. Carry out disinfection and sterilization treatment, put the culture material into the cultivation bottle and use a pressure cooker to sterilize it for 50 minutes. When the production volume is large, the culture material needs to be sterilized for 2 hours, and it can be used after it is taken out and cooled to room temperature;

[0033] Step 3:...

Embodiment 2

[0040] Step 1: Prepare the culture bottle and related equipment: place the culture bottle and related culture equipment in the water basin, and use a brush to perform a thorough basic cleaning. After the culture bottle and related equipment are basically cleaned, place them one by one in the mobile Rinse them twice in distilled water, and place the rinsed related instruments on the top of the workbench to dry;

[0041] Step 2: The configuration of the relevant culture material: use 55 parts of sawdust, 60 parts of distiller’s grains, 15 parts of bagasse, 100 parts of corn cob, 60 parts of chaff, 55 parts of peanut hulls and 75 parts of cottonseed hulls. Carry out disinfection and sterilization, put the culture material into the cultivation bottle and use the pressure cooker to sterilize it for 50 minutes. When the production volume is large, the culture material needs to be sterilized for 2.5 hours, and it can be used after it is taken out and cooled to room temperature;

[0042] S...

Embodiment 3

[0049] Step 1: Prepare the culture bottle and related equipment: place the culture bottle and related culture equipment in the water basin, and use a brush to perform a thorough basic cleaning. After the culture bottle and related equipment are basically cleaned, place them one by one in the mobile Rinse them twice in distilled water, and place the rinsed related instruments on the top of the workbench to dry;

[0050] Step 2: Configuration of relevant culture materials: use 60 parts of sawdust, 70 parts of distillers grains, 20 parts of bagasse, 120 parts of corn cobs, 70 parts of chaff, 60 parts of peanut hulls and 90 parts of cottonseed hulls. Carry out disinfection and sterilization treatment, put the culture material into the cultivation bottle and use a pressure cooker to sterilize it for 50 minutes. When the production volume is large, the culture material needs to be sterilized for 3 hours, and it can be used after it is taken out and cooled to room temperature;

[0051] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com