Preparation method and application of boron nitride block adsorbent for treating iodine vapor pollutants

A boron nitride and pollutant technology, applied in chemical instruments and methods, gas treatment, nitrogen compounds, etc., can solve the problems of difficulty in recycling, low thermal stability, adsorption capacity in service, etc., to achieve large output and reduce energy. The effect of reducing consumption and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

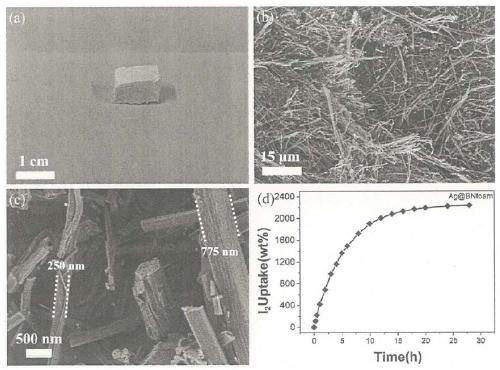

Embodiment 1

[0041] (1) 0.424gAgNO 3 Dissolve in 5mL deionized water and prepare a metal ion solution with a concentration of 0.0025mol / L for later use.

[0042] (2) boric acid and melamine are mixed in 250mL beaker and add 245mL deionized water, make precursor solution, make the boric acid that contains the melamine of 0.018g and 0.0126g in every milliliter of water; The amount of substance of boric acid and melamine The ratio is 3:1;

[0043] (3) Put the precursor solution in step (2) into a constant temperature stirrer at 90° C. and stir for 2 hours to completely dissolve the boric acid and melamine.

[0044] (4) Transfer 245 mL of the solution obtained in step (3) to room temperature for stirring, and pour 5 mL of the solution containing metal ions prepared in (1) into while stirring. Stir for 3min.

[0045] (5) Transfer the beaker in step (4) to an ultrasonic instrument that has been cooled to 10°C in advance, and perform ultrasonication at 45KHz, 350W, and 50% power for 4 hours un...

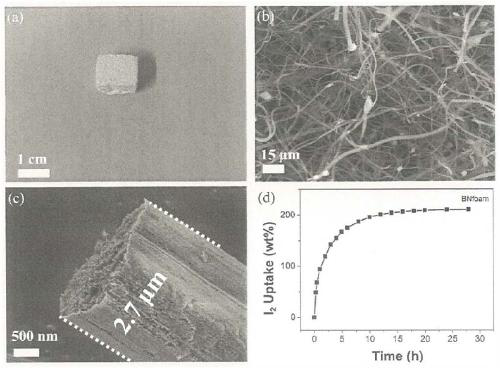

Embodiment 2

[0050] After the adsorption in Example 1 is completed, the BN block adsorbent is placed at a high temperature of 200°C for iodine vapor desorption treatment. After the desorption is completed, the adsorption experiment is repeated in cycles. After 5 repeated cycles, the obtained adsorption results are approximately Example 1.

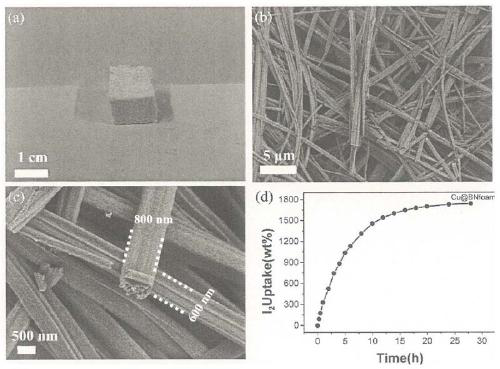

Embodiment 3

[0052] Change the heat treatment temperature in Example 1 to 1050° C., other operations are the same as in Example 1, and the product obtained is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com