Heat-resistant single-component addition type organosilicone adhesive and preparation method thereof

A technology of organic silica gel and heat-resistant additives, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of poor thermal stability and achieve the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

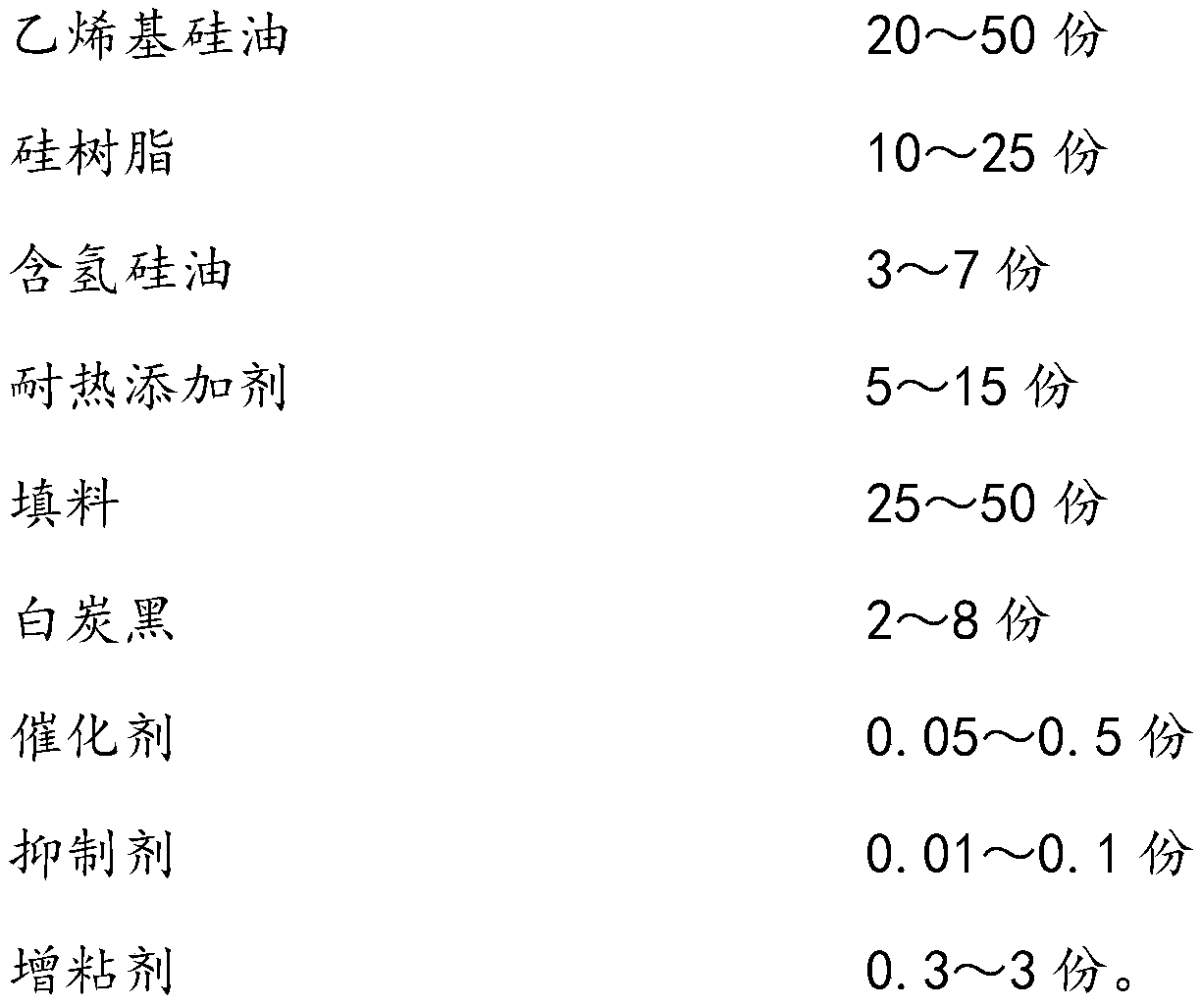

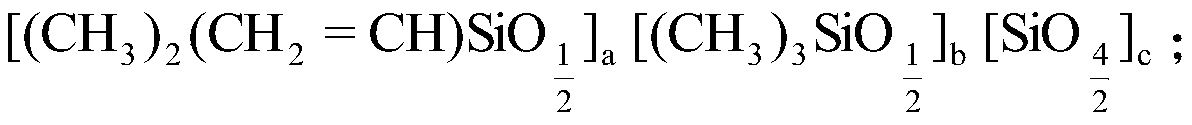

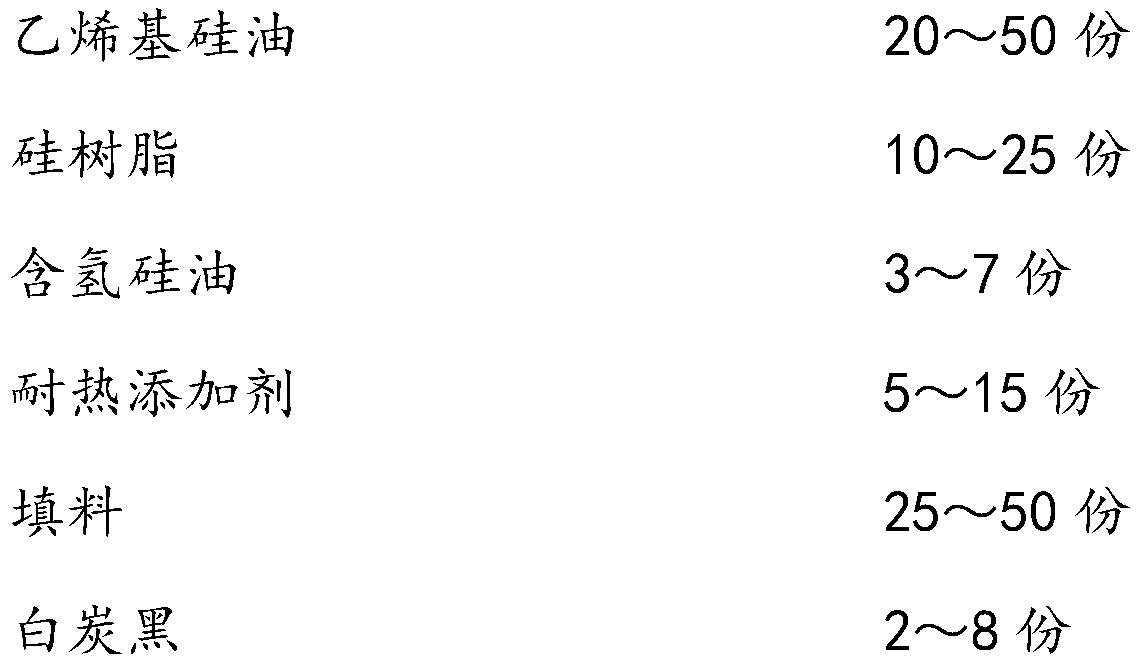

Method used

Image

Examples

Embodiment 1

[0056] ⑴ Preparation of tackifier

[0057] ①Add 3 parts of cyclohexane, 3 parts of methanol, 7 parts of water, 1.5 parts of 3-(2,3-epoxypropoxy)propylmethyldiethoxysilane, 1 part of γ-methanol into the three-necked flask Acryloyloxypropyltrimethoxysilane; ② Slowly add a mixture of 2 parts of trimethylchlorosilane and 3 parts of methylhydrogendichlorosilane in ① under stirring, and slowly add 2 parts of ethyl borate dropwise; ③ After completing step ②, continue to stir for 2 hours; ④ Wash the product in step ③ with water, remove acid, water, alcohol, and cyclohexane to obtain a thickener.

[0058] (2) At room temperature, add 25 parts of Zhejiang Runhe Chemical RH-Vi305, 25 parts of Jiangxi Xinjiayi XJY-8206N, 6 parts of Zhejiang Runhe Chemical RH-H503, 0.03 parts of 3-methyl-1-butyne- 3-alcohol, 1.2 parts of homemade tackifier in the above (1), stir and disperse evenly.

[0059] (3) Add 0.1 part of Shanghai Sibao ACS-Pt-30 to (2) at room temperature, stir to disperse and mix...

Embodiment 2

[0062] ⑴ Preparation of tackifier

[0063] ① Add 4 parts of cyclohexane, 4 parts of methanol, 8 parts of water, and 3 parts of 3-(2,3-epoxypropoxy)propylmethyldiethoxysilane into the three-necked flask; Slowly add a mixture of 3 parts of trimethylchlorosilane and 5 parts of methylhydrogendichlorosilane dropwise, and slowly add a mixture of 1 part of tributyl borate and 2 parts of tripropyl borate; ③ on the basis of completing step ② and continue to stir for 3 hours; ④Wash the product in step ③ with water, remove acid, remove water, remove alcohol, and remove cyclohexane to obtain a thickener.

[0064] (2) At room temperature, add 35 parts of Zhejiang Runhe Chemical RH-Vi303, 16 parts of Zhejiang Runhe Chemical RH-S0835, 5 parts of Zhejiang Runhe Chemical RH-H536, 0.04 parts of 1-ethynyl cyclohexanol, 1.5 parts of In the above ⑴, make the tackifier by yourself, stir and disperse evenly.

[0065] (3) Add 0.15 parts of Shanghai Sibao ACS-Pt-30 to (2) at room temperature, stir t...

Embodiment 3

[0068] ⑴ Preparation of tackifier

[0069] ①Add 5 parts of cyclohexane, 5 parts of methanol, 9 parts of water, 1.5 parts of 3-(2,3-epoxypropoxy)propylmethyldiethoxysilane, 1 part of 3-( 2,3-Glycidoxy)propyltrimethoxysilane; ② Slowly add a mixture of 3 parts of trimethylchlorosilane and 6 parts of methylhydrogendichlorosilane dropwise in ① under stirring, and slowly add 2 parts of Tripropyl borate; ③ After completing step ②, continue to stir for 3 hours; ④ Wash the product in step ③ with water, remove acid, remove water, remove alcohol, and remove cyclohexane to obtain a tackifier.

[0070] (2) At room temperature, add 30 parts of Shandong Dayi DY-V401, 18 parts of Zhejiang Runhe Chemical RH-S0836, 3 parts of Zhejiang Runhe Chemical RH-H503, 2 parts of Zhejiang Runhe Chemical RH-H536, 0.04 parts of 3 - Methyl-1-butyn-3-ol, 0.8 part of the above-mentioned ⑴ homemade tackifier, stirring and dispersing evenly.

[0071] (3) Add 0.1 part of Shin-Etsu CAT-PL-56 to (2) at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com