Evaporator, cold and heat combined supply system and vacuum generator

A technology of vacuum generator and combined cooling and heating, applied in machine/engine, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problem of increasing equipment investment and energy consumption, inability to continuously evaporate waste water, low treatment efficiency, etc. problems, to achieve the effect of high waste liquid treatment efficiency, high energy utilization efficiency, and low pollutant concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with accompanying drawing:

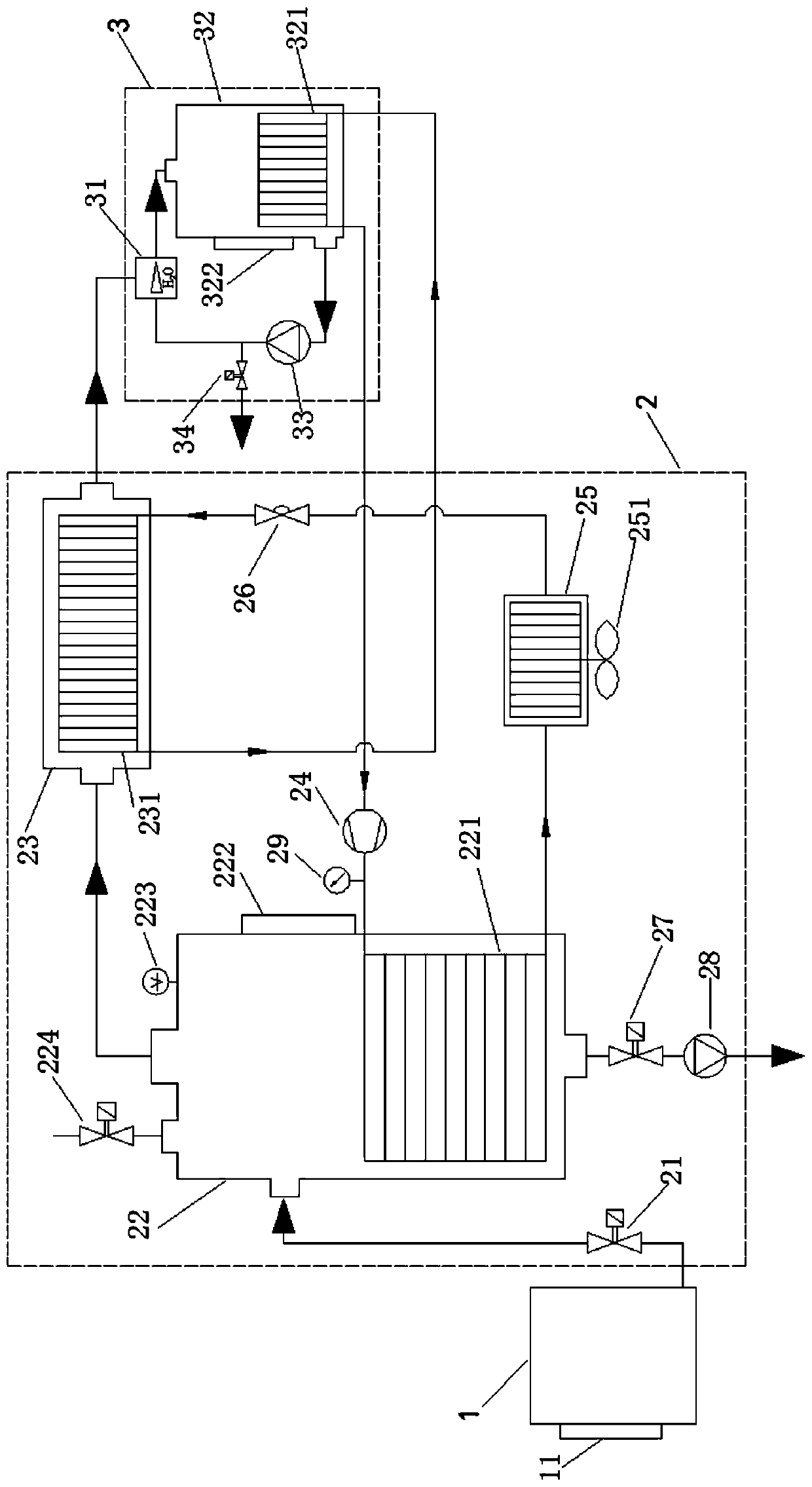

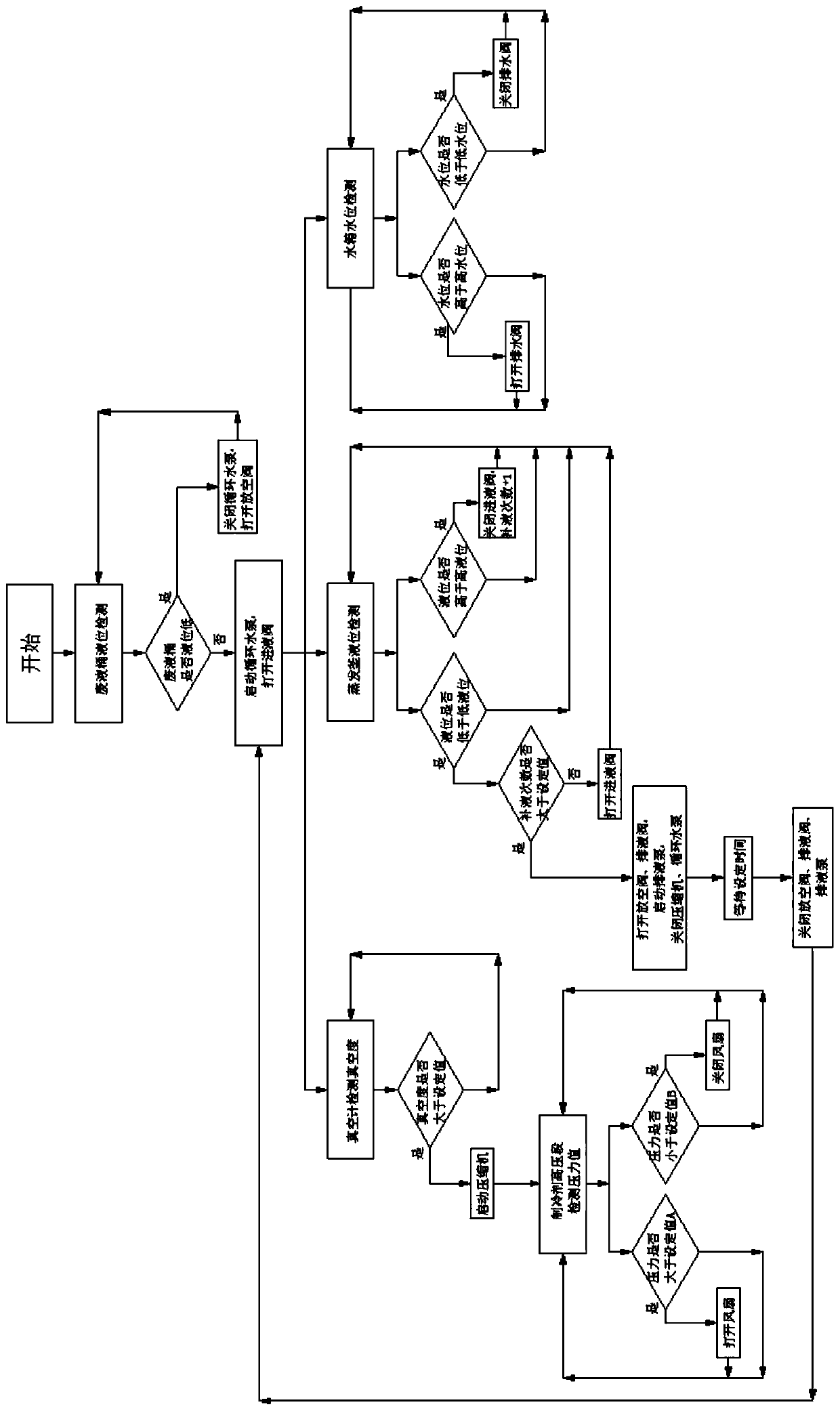

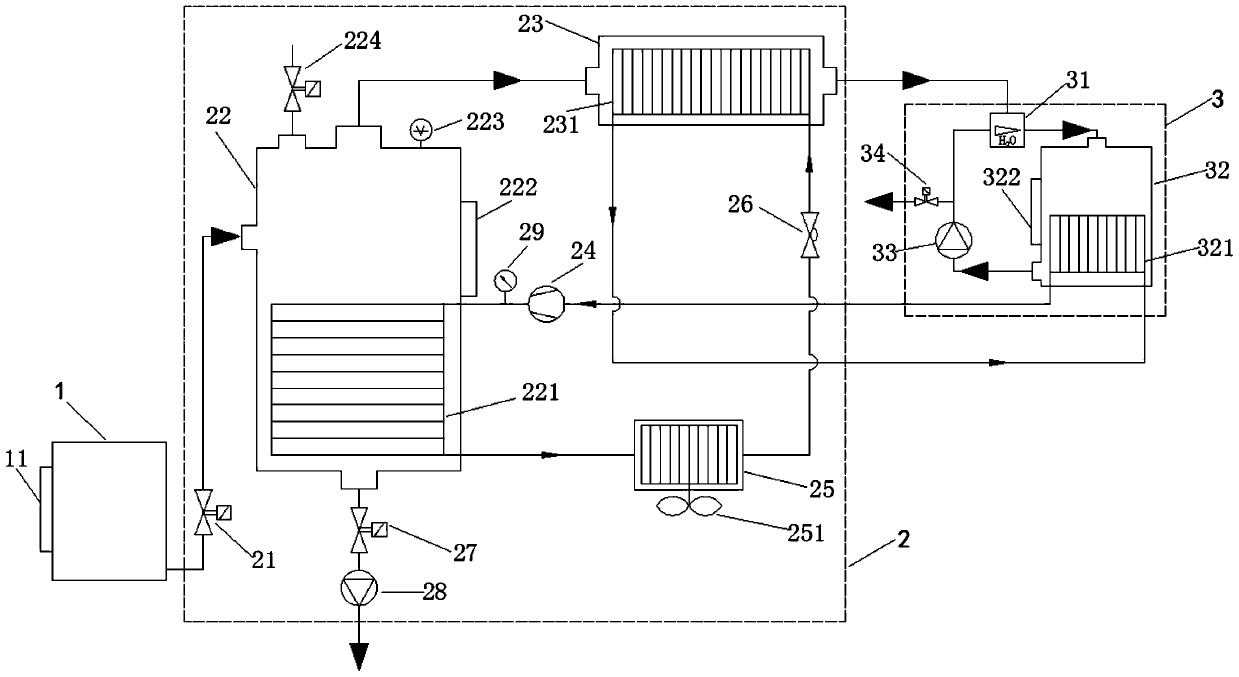

[0036] see figure 1As shown, the evaporator includes a waste liquid bucket 1 , a combined cooling and heating system 2 and a vacuum generator 3 . The waste liquid barrel 1 is provided with a first liquid level sensor 11, and the combined cooling and heating system 2 includes an evaporation kettle 22, a condenser 23, a compressor 24, a radiator 25, and an expansion valve 26. A first coil 221 is provided, and the evaporator 22 is respectively provided with a second liquid level sensor 222, a vacuum gauge 223, a vent valve 224, a liquid inlet valve 21 connected to the waste liquid barrel 1, and a liquid outlet valve connected to the liquid discharge pump 28. A drain valve 27, a second coil 231 is provided in the condenser 23; the vacuum generator 3 includes an ejector 31, a circulating water tank 32, and a circulating water pump 33 connected in sequence through pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com