Radical scavenger, manufacturing method therefor, membrane-electrode assembly comprising same, and fuel cell comprising same

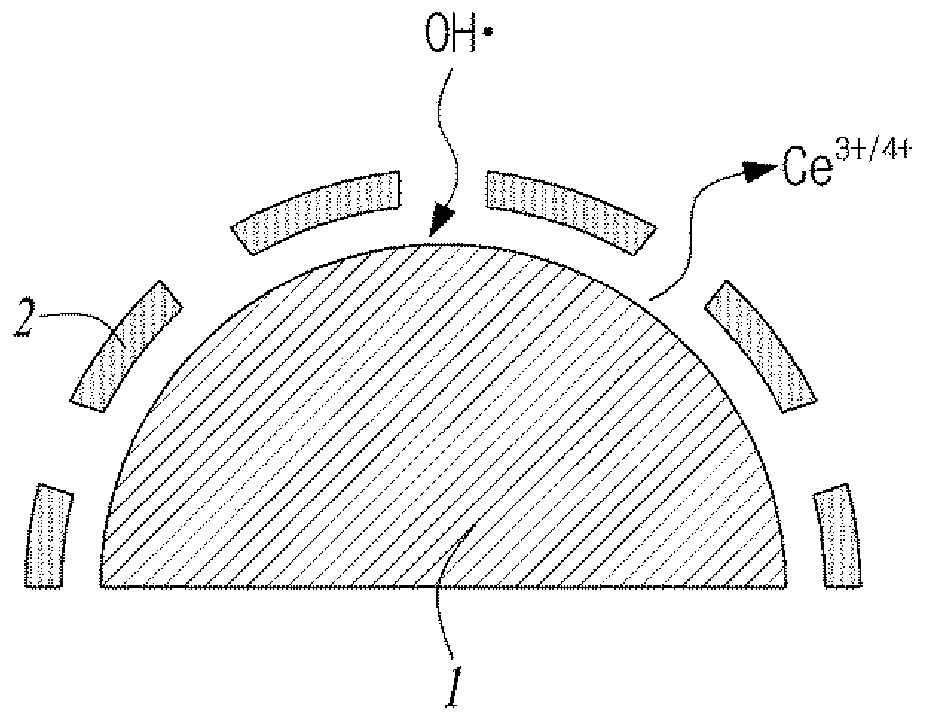

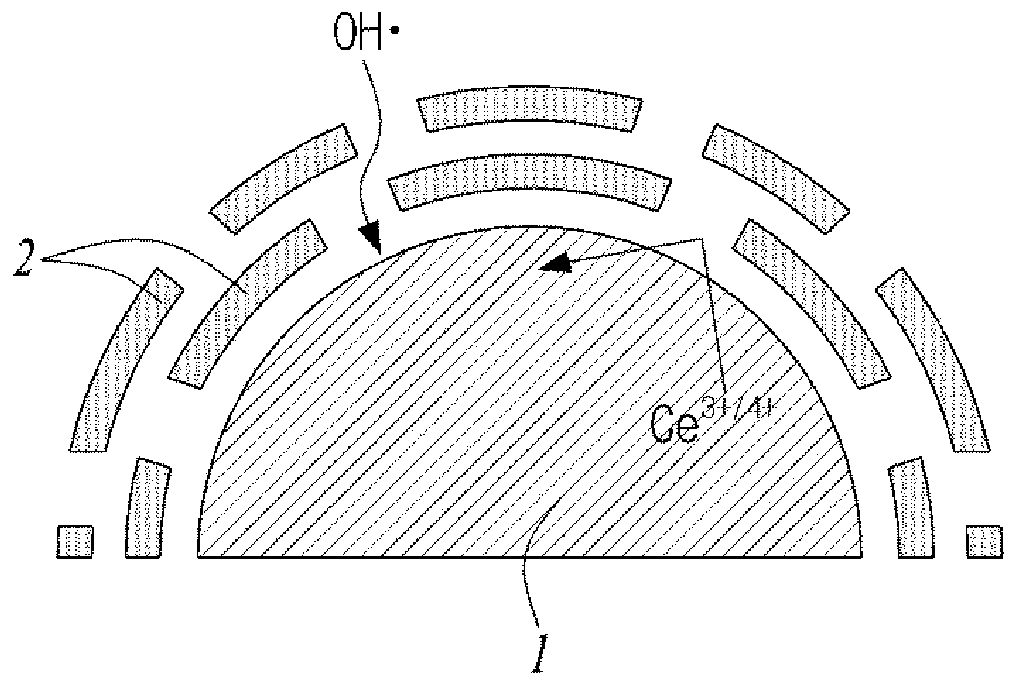

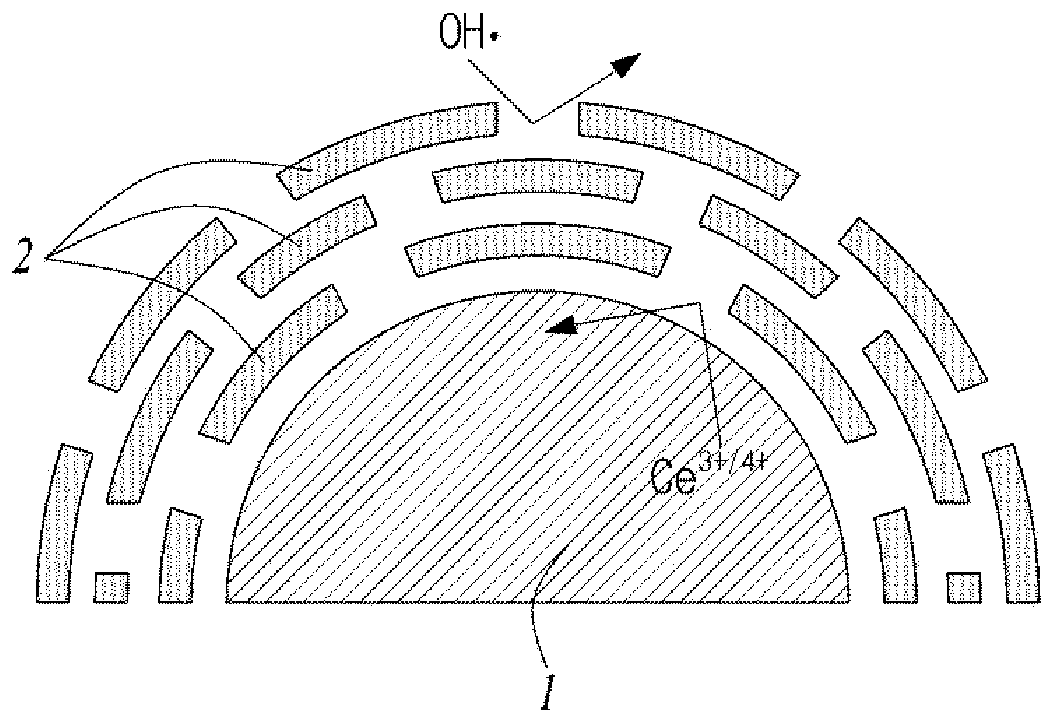

A technology of free radicals and scavengers, used in fuel cells, electrical components, battery electrodes, etc., can solve the problems of reducing the ionic conductivity of ion exchange membranes, reducing the output performance of fuel cells, etc., to prevent chemical degradation and achieve excellent long-term performance. , The effect of improving chemical durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation method of a free radical scavenger according to another embodiment of the present disclosure includes the step of coating a carbon precursor on the surface of a core particle capable of decomposing peroxides or free radicals, the core particle being selected from transition Any one of metal, noble metal, transition metal or noble metal ion, transition metal or noble metal salt, transition metal or noble metal oxide, and mixtures thereof; and carbonizing the carbon precursor on the surface of the core particle to A step of forming a porous carbon coating.

[0063] The descriptions of the particles capable of decomposing peroxides or radicals and the porous carbon coating are the same as those described above, and thus repeated descriptions thereof will be omitted.

[0064] Meanwhile, the step of coating the carbon precursor on the surface of the core particle may specifically include the step of adding the carbon precursor to a solvent to prepare a compos...

preparation Embodiment 1

[0139] [Preparation Example 1: Preparation of Radical Scavenger]

Embodiment 1-1

[0141] Dopamine is added to the tris-hydrochloride buffer solution in order to prepare the composition for coating the carbon precursor, and will be able to decompose peroxide or free radical core particles such as CeO 2 Added to the composition for coating carbon precursor. At this time, the composition for coating the carbon precursor contained 0.3 parts by weight of the carbon precursor based on 100 parts by weight of the core particles.

[0142] The composition for coating the carbon precursor with core particles added thereto was stirred at 250 rpm for 12 hours at 25°C, the carbon precursor was stabilized in a nitrogen atmosphere at 250°C, and the carbon precursor was stabilized at 700°C carbonized in a nitrogen atmosphere to prepare a radical scavenger having a porous carbon coating formed on the surface of the core particle.

[0143] In the prepared free radical scavenger, the thickness of the porous carbon coating is 2nm to 5nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com