Preparation method of ultra-long few-walled carbon nanotube array

A carbon nanotube array and ultra-long technology, which is applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems such as difficult to realize the preparation of long array carbon nanotubes, low growth rate, cumbersome purification process, etc. It is beneficial to macro preparation and large-scale application, and solves the effect of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

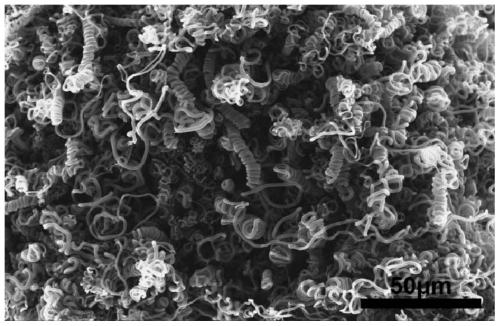

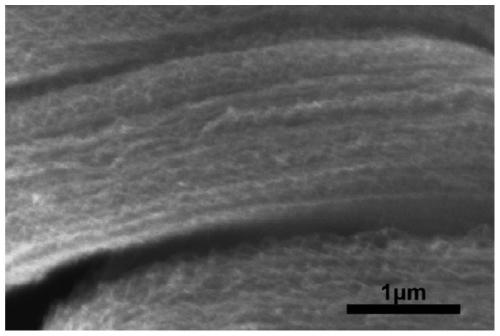

[0019] The invention discloses a preparation method of an ultra-long few-walled carbon nanotube array. The method uses a sheet material as a carrier, regulates the size and distribution density of catalyst active particles through a stoichiometric ratio, and uses cheap carbon-containing gas or liquid as a carbon source. , the catalyst is loaded through the container, and sulfur is introduced to fully increase the contact surface between the catalyst and the carbon source gas and expand the space for carbon tube growth, and prepare a few-walled ultra-long carbon nanotube array with a growth rate of The ratio of the mass of the nanotube to the mass of the catalyst used is more than 10 times.

[0020] Described method specifically comprises the following steps:

[0021] S1) Prepare the sheet catalyst, disperse the prepared catalyst on the container, and set aside;

[0022] S2) Put the container treated in S1) in the reactor, vacuumize it, feed inert gas, heat, feed mixed gas, co...

Embodiment 1

[0038] Example 1: Preparation of ultra-long carbon nanotube arrays from Fe / Mg / Al sheet material liquefied petroleum gas carbon source.

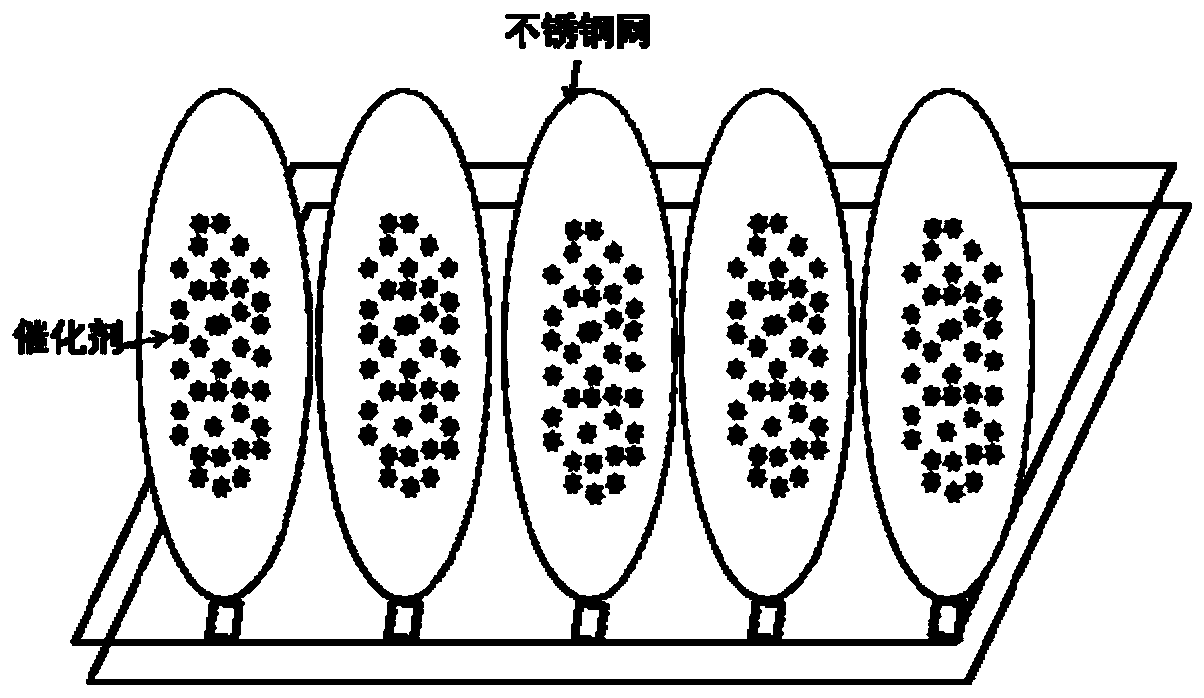

[0039] The active metal iron is loaded onto the layered double hydroxy metal hydroxide sheet material, and the stoichiometric ratio is adjusted so that iron accounts for 10wt% of the sheet material, and the Fe / Mg / Al sheet catalyst is prepared by coprecipitation method, which will be prepared The catalyst in the ethanol solvent was ultrasonically dispersed for 20 minutes, and the dispersion was even. The mass ratio of the catalyst to ethanol was 1:200. The dispersed solution was sprayed on the stainless steel mesh with a watering can, and the distribution density of the catalyst on the stainless steel mesh was 1mg / cm 3 , place the stainless steel mesh sprayed with the catalyst neatly in the tube furnace as figure 1 As shown, the arrangement of multi-layer stainless steel mesh increases the utilization rate of the tube furnace while making the ...

Embodiment 2

[0040] Example 2: Fe / Mg / Al sheet material liquefied natural gas plus sulfur carbon source to prepare ultra-long carbon nanotube arrays.

[0041] The active metal iron is loaded onto the layered double hydroxy metal hydroxide sheet material, and the stoichiometric ratio is adjusted so that iron accounts for 10wt% of the sheet material, and the Fe / Mg / Al sheet catalyst is prepared by coprecipitation method, which will be prepared The catalyst in the ethanol solvent was ultrasonically dispersed for 20 minutes, and the dispersion was even. The mass ratio of the catalyst to ethanol was 1:200. The dispersed solution was sprayed on the stainless steel mesh with a watering can, and the distribution density of the catalyst on the stainless steel mesh was 1mg / cm 3 , place the stainless steel mesh sprayed with the catalyst neatly in the tube furnace. After evacuation, 1000 sccm argon gas was introduced to scrub the gas, and the temperature was raised to 900 °C under the protection of argo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com