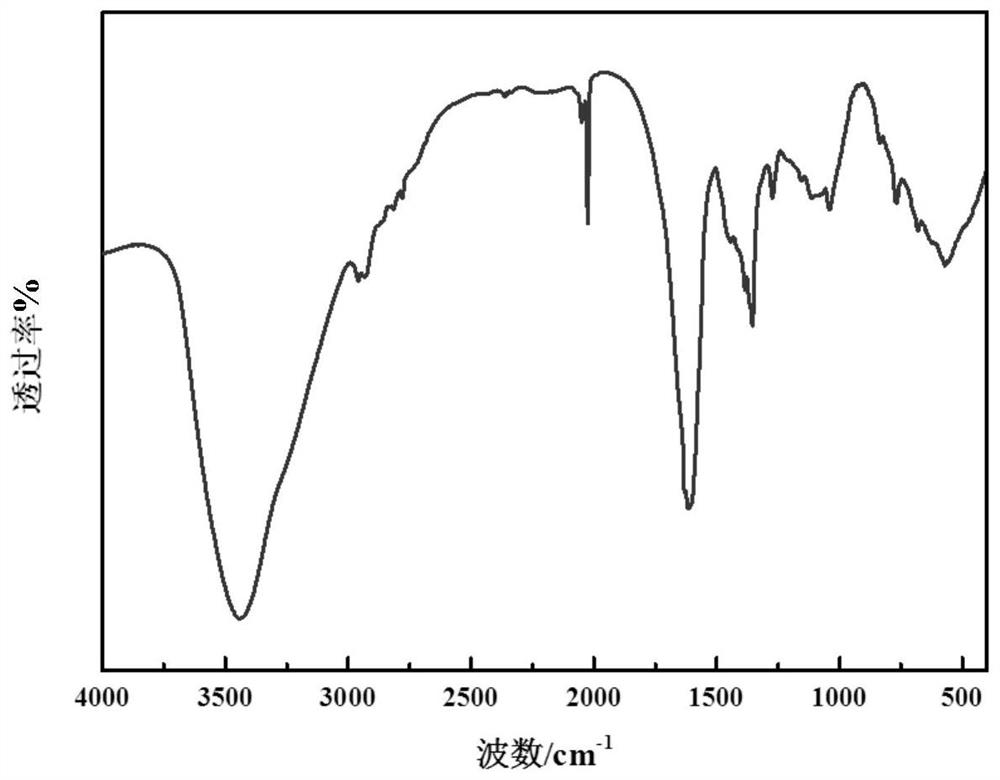

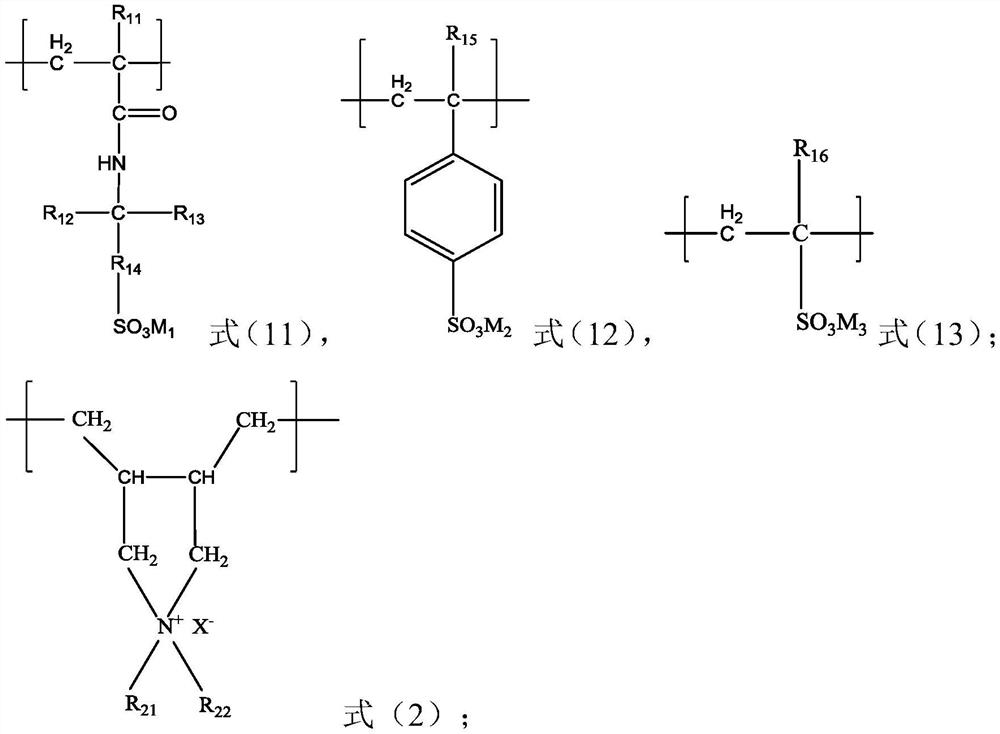

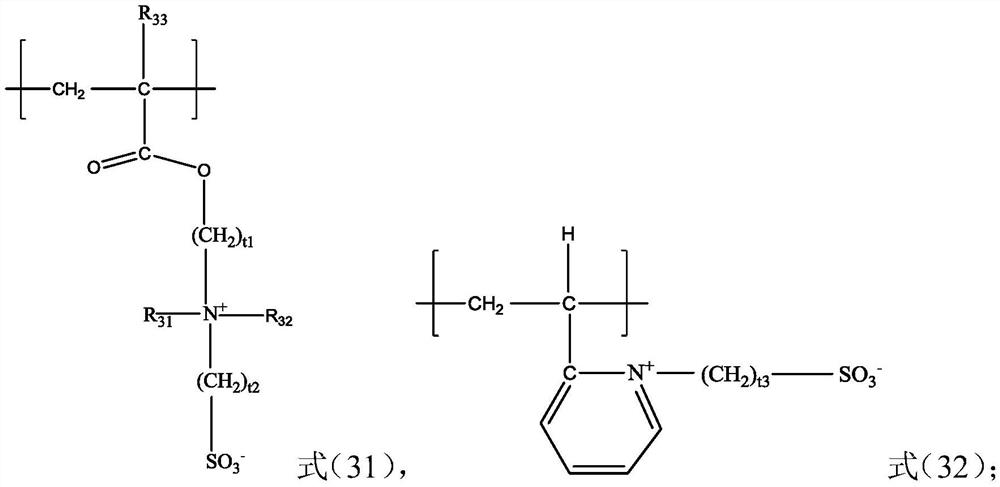

Anti-calcium zwitterionic polymer, preparation method and application thereof, and water-based drilling fluid containing said polymer as dispersant

A water-based drilling fluid and zwitterion technology, applied in the field of drilling fluid, can solve the problems of large filtration loss and poor dispersion, and achieve the effects of good dispersion, good compatibility and easy dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0076] In the present invention, according to a preferred embodiment, the preparation method of the polymer comprises the following steps:

[0077] (1) monomer A ', described monomer B ' and described monomer C ' are added in the there-necked flask filled with distilled water, stir until monomer is mixed, wherein, based on the consumption of distilled water, monomer The total dosage is 30-50% by weight;

[0078] (2) adding cosolvent, chain transfer agent and initiator to the aqueous solution of step (1), stirring uniformly;

[0079] (3) After the addition is completed, the three-necked flask is sealed and a nitrogen-passing device is added, and nitrogen is introduced into the three-necked flask. After fully removing the air in the bottle, the temperature is increased at 45-75 ° C to carry out the polymerization reaction for 7-10h, and after the reaction is completed, it reaches At room temperature, a solution containing the polymer was obtained.

[0080] The preparation meth...

Embodiment 1

[0119] (1) The polymer composition (58.32g of monomer A', 15.12g of monomer B' and 6.56g of monomer C') was added to a three-necked flask containing 200g of distilled water, and carried out at 25°C Heating in a water bath, stirring until the monomers are evenly mixed, the monomer A' is the sodium 2-acrylamido-2-methylpropanesulfonate of the structure shown in formula (I4); the monomer B' is the formula (IV) ) the diallyl dimethyl ammonium chloride of the structure shown; Described monomer C ' is the methacryloyl ethyl sulfobetaine of the structure shown in formula (V1);

[0120] (2) the aqueous solution of step (1) is added the sodium chloride of 20g, the sodium formate of 0.24g and the potassium persulfate of 0.4g, stir;

[0121] (3) After the addition is completed, the three-necked flask is sealed and a nitrogen-passing device is added to introduce nitrogen into the three-necked flask. After fully removing the air in the flask, the temperature is raised to 70° C., and the po...

Embodiment 2-3

[0124] The polymer was prepared in a manner similar to that of Example 1, except that the types of the monomers A' used were different, and the rest were the same as in Example 1, and polymers S2 and S3 were obtained respectively, specifically:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com