Formaldehyde-removing polymer composite material and preparation method thereof

A composite material and polymer technology, which is applied in the field of formaldehyde-removing polymer composite materials and its preparation, can solve problems such as unsatisfactory formaldehyde-removing effect, and achieve the effect of simple preparation method and fresh air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

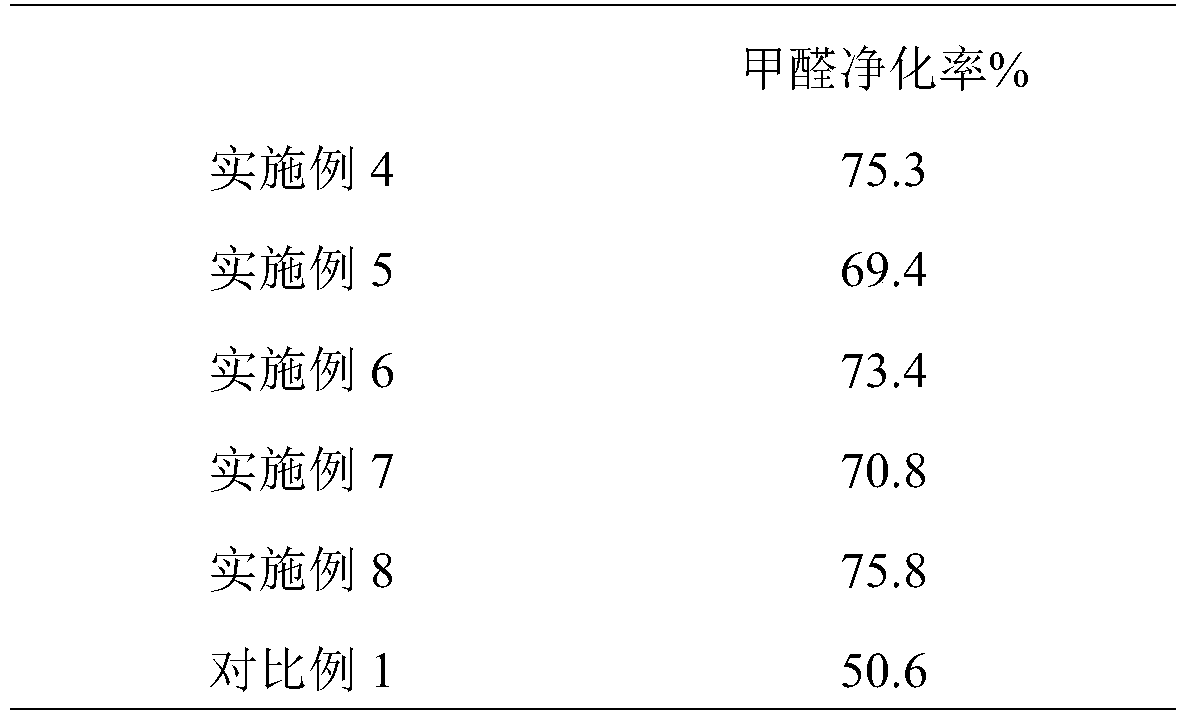

Examples

preparation example Construction

[0035] It should be noted that the modified activated carbon preparation method comprises the following steps;

[0036] 1) Add activated carbon to 0.1mol / L hydrochloric acid and soak for 24 hours, then backwash with water until the pH of the filtered water is 6-7, then separate the activated carbon, dry at 30-40°C for 2-3 hours, and set aside;

[0037] 2) Mix the activated carbon obtained in step 1) with the composite bacteria, culture at 35-40°C for 24-36h, and dry at 35-40°C to obtain modified activated carbon;

[0038] The mass ratio of activated carbon to composite bacteria is 1: (0.1-0.15).

[0039] Among them, the composite bacteria include formaldehyde-degrading bacteria and bacillus with a mass ratio of 1:1.

[0040] Composite bacteria are attached to the modified activated carbon prepared above, the activated carbon absorbs formaldehyde in the air, and the composite bacteria decompose the adsorbed formaldehyde, thereby enabling the modified activated carbon to mainta...

Embodiment 1

[0055] The modified activated carbon is microbial modified activated carbon, and the preparation method comprises the following steps;

[0056] 1) Add activated carbon to 0.1mol / L hydrochloric acid and soak for 24 hours, then backwash with water until the pH of the filtered water is 7, then separate the activated carbon, dry at 40°C for 3 hours, and set aside;

[0057] 2) Mix the activated carbon obtained in step 1) with the composite bacteria, culture at 35°C for 36 hours, and dry at 40°C to obtain modified activated carbon; the composite bacteria include formaldehyde-degrading bacteria with a mass ratio of 1:1 and Bacillus;

[0058] The mass ratio of activated carbon to composite bacteria is 1:0.15.

Embodiment 2

[0060] The modified activated carbon is microbial modified activated carbon, and the preparation method comprises the following steps;

[0061] 1) Add activated carbon to 0.1mol / L hydrochloric acid and soak for 24 hours, then backwash with water until the pH of the filtered water is 6, then separate the activated carbon, dry at 30°C for 2-3 hours, and set aside;

[0062] 2) Mix the activated carbon obtained in step 1) with the composite bacteria, culture at 40°C for 24 hours, and dry at 35°C to obtain modified activated carbon; the composite bacteria include formaldehyde-degrading bacteria with a mass ratio of 1:1 and Bacillus;

[0063] The mass ratio of activated carbon to composite bacteria is 1:0.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com