Method for reducing methanol content in apple fermented wine

A methanol content, cider technology, applied in the field of food processing, can solve the problem of reducing methanol without research, and achieve the effect of reducing pectin decomposition, mellow and soft taste, and balanced taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

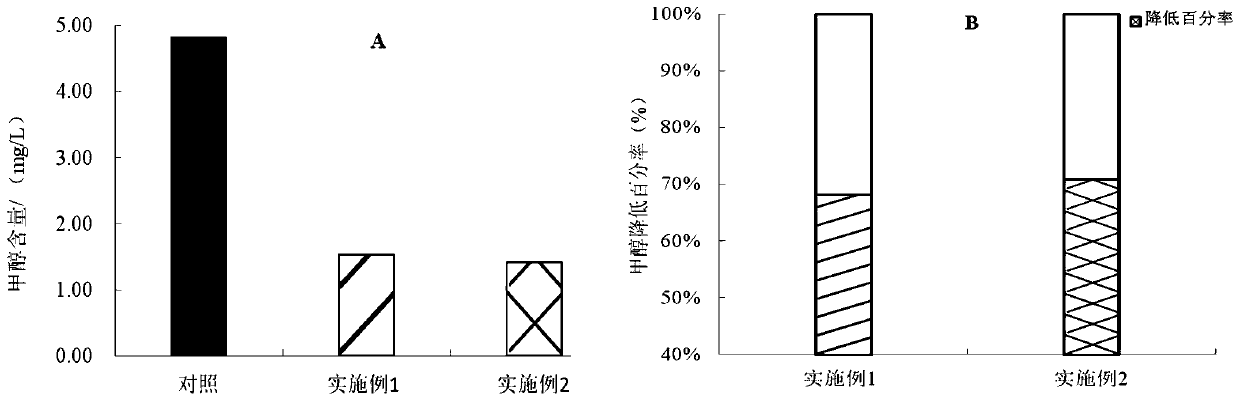

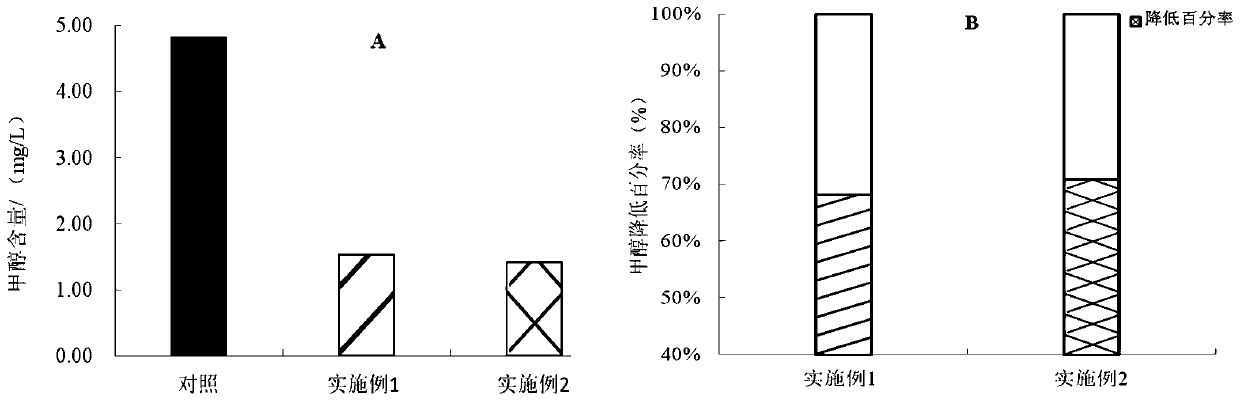

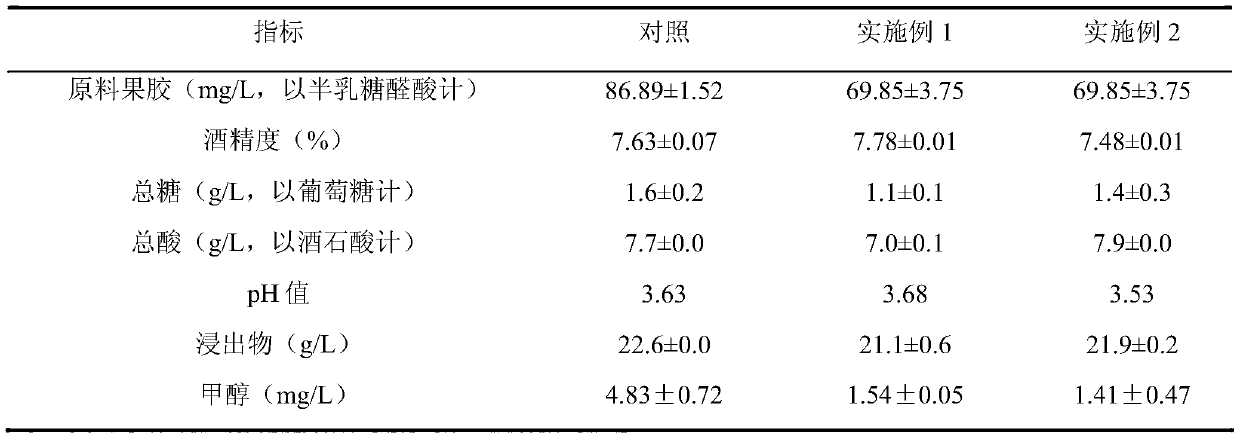

Examples

Embodiment 1

[0024] 1) Choose healthy apples and squeeze the juice for later use;

[0025] 2) Activation of bentonite: Add hot water at 60°C to the bentonite until the bentonite is submerged, mix well and place at room temperature for 24 hours (record the mass of hot water used and calculate the concentration of bentonite at this time). Dilute the activated bentonite concentration to 5% with the apple juice prepared in step 1) to obtain a bentonite suspension; set aside;

[0026] 3) Add the bentonite suspension diluted to 5% after activation in step 2) into the remaining apple juice prepared in step 1), so that the content of bentonite in the apple juice is 1.5 g / kg, and fully mix;

[0027] 4) Inoculate active dry wine yeast in apple juice according to the ratio of 0.25g / kg, and carry out alcoholic fermentation at 10°C;

[0028] 5) During the fermentation process, the sugar content is measured with a sugar meter, and when the residual sugar reaches the final sugar content to be prepared f...

Embodiment 2

[0031] 1) Choose healthy apples and squeeze the juice for later use;

[0032] 2) Bentonite activation: add 80°C hot water to the bentonite until the bentonite is submerged, mix well and place at room temperature for 24 hours. Dilute the activated bentonite with apple juice to a concentration of 5% suspension, and set aside;

[0033] 3) Add the activated bentonite suspension in the apple juice so that the bentonite content in the apple juice is 2.5g / kg, and mix well;

[0034] 4) Inoculate active dry wine yeast in apple juice according to the ratio of 0.25g / kg, and carry out alcoholic fermentation at 22°C;

[0035] 5) During the fermentation process, the sugar content is measured with a sugar meter, and when the residual sugar reaches the final sugar content to be prepared for cider, the fermentation liquid is immediately cooled to close to the freezing point of the cider, and the yeast is separated;

[0036] 6) aging, clarification, filtration. Filling to obtain finished cid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com