Compaction machine for towed plum-blossom-shaped roller impact filling of soil and stone block wastes

A plum blossom and waste technology, applied in soil protection, roads, road repair and other directions, can solve problems such as affecting the construction efficiency of construction machinery, reducing the quality of compaction operations, and affecting the value of the seismic coefficient of the foundation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

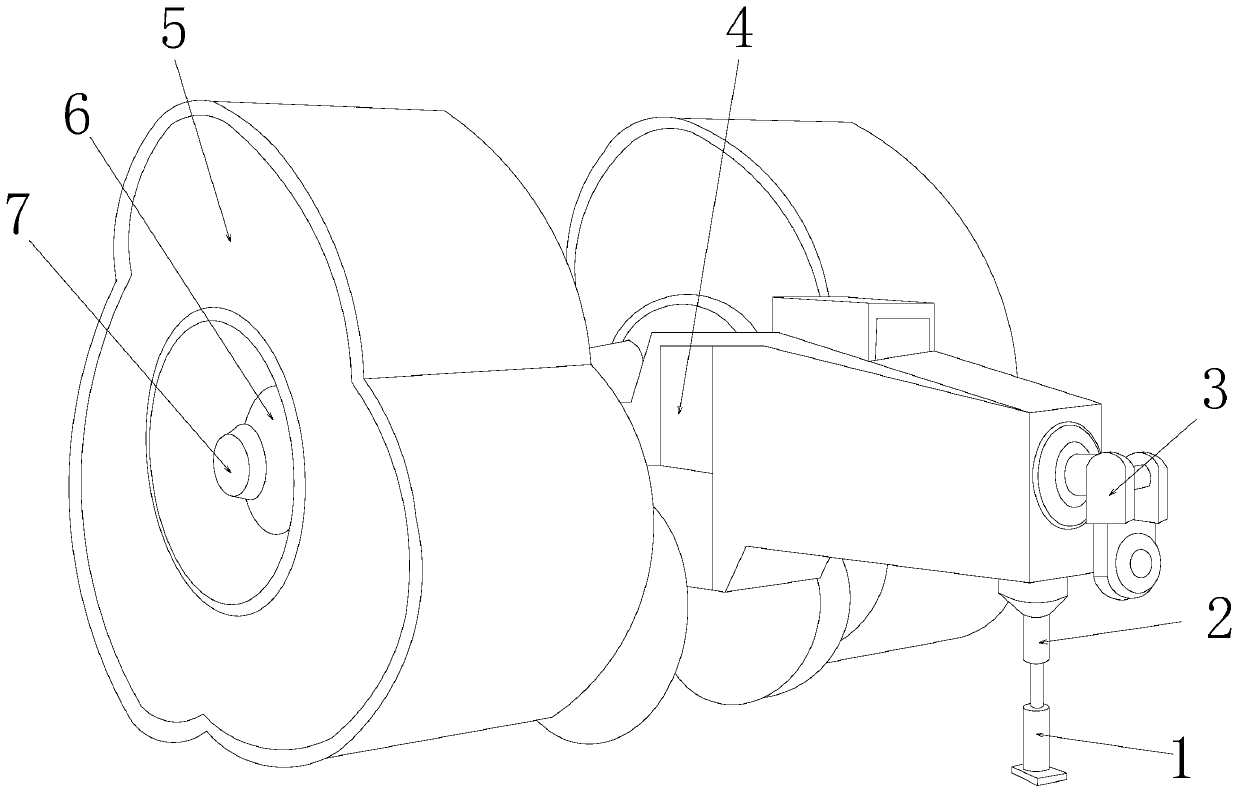

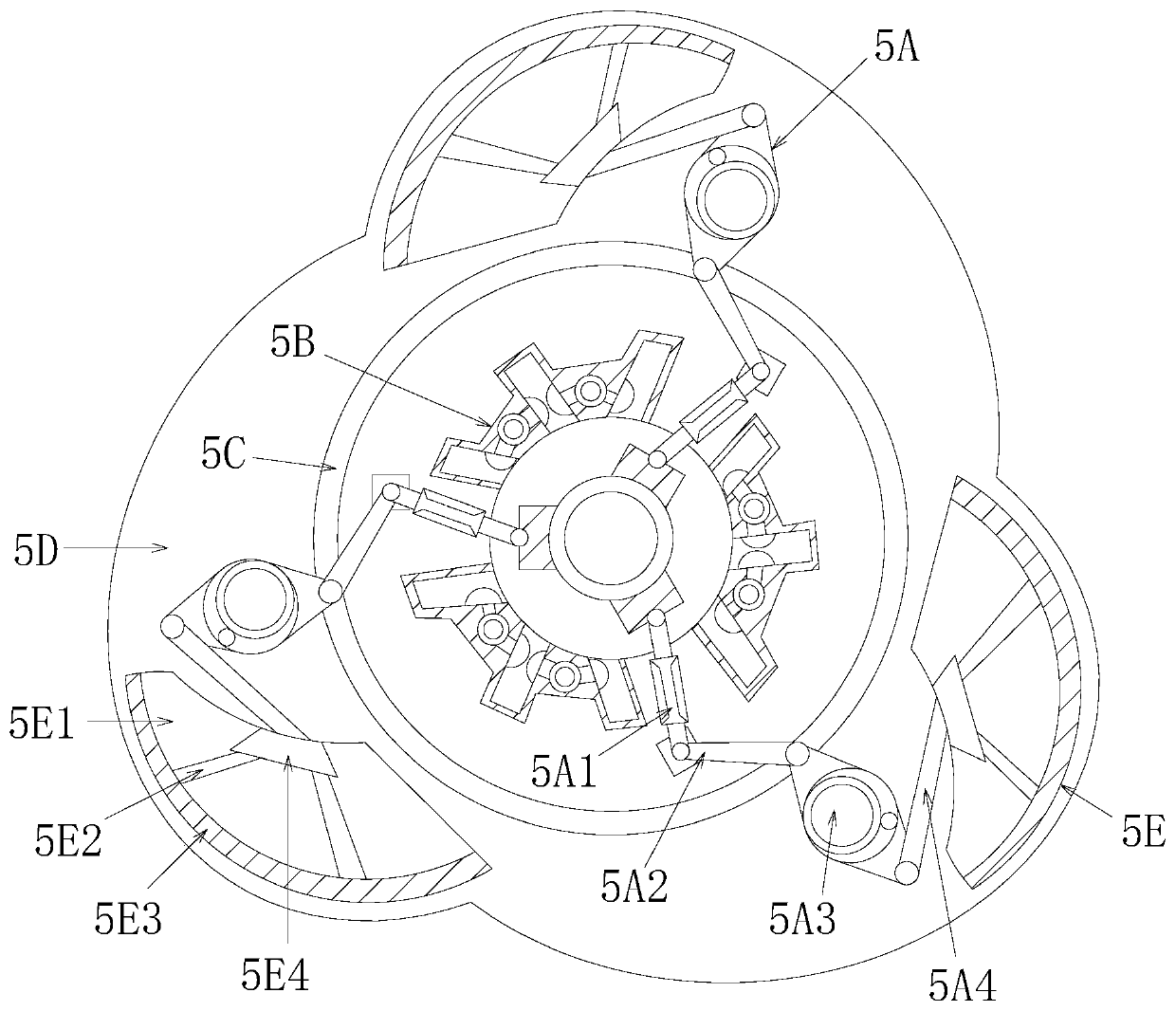

[0031] see Figure 1-Figure 6, the present invention provides a kind of compacting machine used for the impact filling of soil and stone waste with towed plum blossom mill, its structure includes: support column 1, oil pressure cylinder 2, lock clip seat 3, lock shaft lifter 4, plum blossom Roller wheel groove 5, shaft cover cap 6, linkage roller bar 7, the plum blossom roller wheel groove 5 is mechanically connected with the linkage roller bar 7 and the axes are collinear, and the shaft cover cap 6 is fastened with the linkage roller bar 7 Together and the axes are collinear, the linkage roller 7 is movably connected with the lock shaft lifter 4, the lock clip seat 3 is installed on the right side of the lock shaft lifter 4 and is on the same level, the The support column 1 is inserted under the bottom of the oil pressure cylinder 2 and is on the same vertical line. The oil pressure cylinder 2 is close to the lower right corner of the lock shaft lifter 4 and is perpendicular ...

Embodiment 2

[0037] see Figure 1-Figure 6 , the present invention provides a kind of compacting machine used for the impact filling of the towed plum blossom mill for soil and stone waste, other aspects are the same as in Embodiment 1, the difference is:

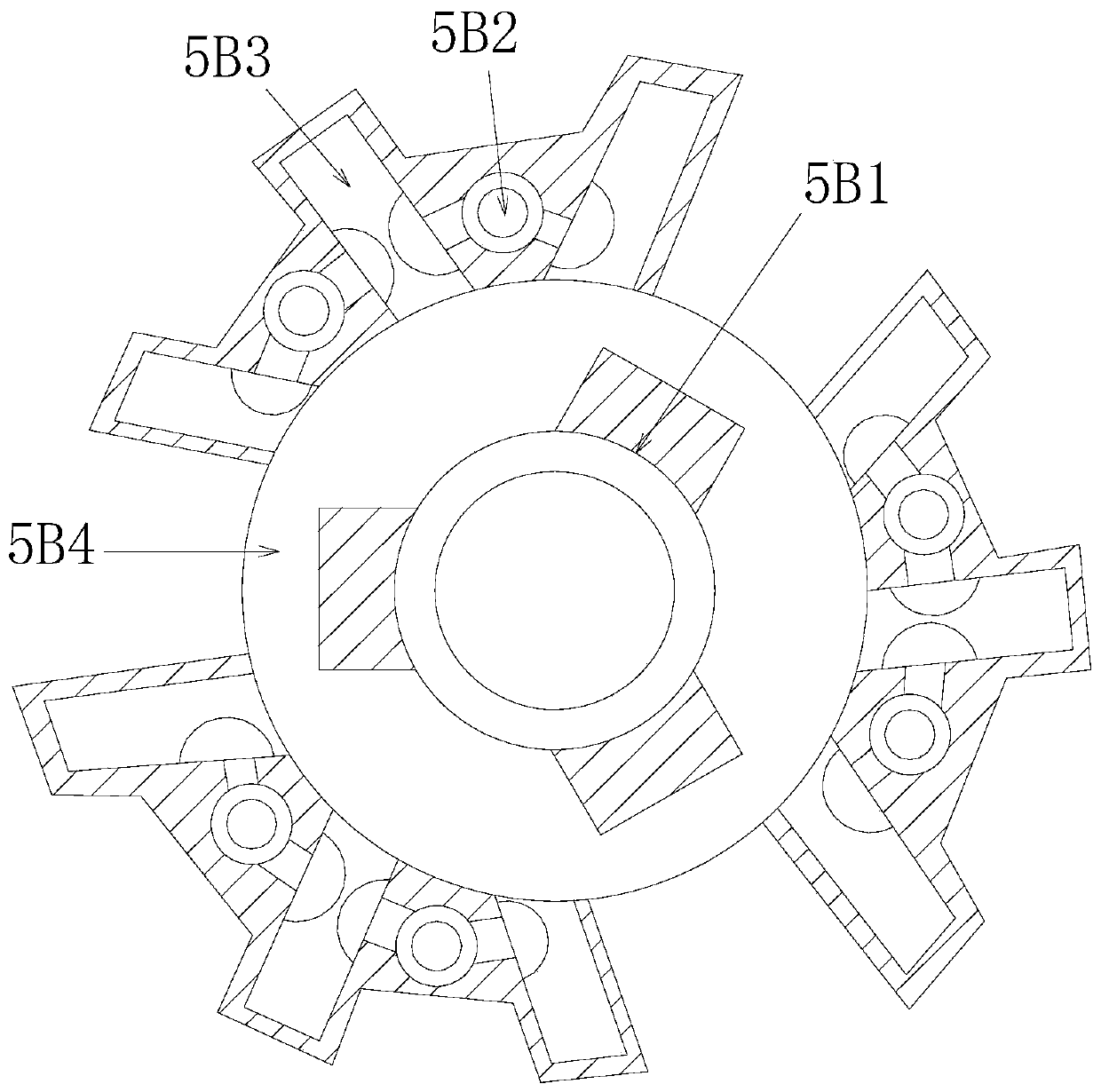

[0038] see image 3 , the ratchet torsion disc 5B is composed of a bump clamp shaft wheel 5B1, a double-bar buckle wheel 5B2, a fin plate 5B3, and a twist disc 5B4, and the double-bar buckle wheel 5B2 and the fin plate 5B3 adopt an interference fit And on the same vertical plane, the finned plate 5B3 is welded together with the twisted disc 5B4, and the bump clamping wheel 5B1 is closely attached to the front side of the twisted disc 5B4, and is superimposed by the bump clamping wheel 5B1 Twisting the disc 5B4 forms a concentric fillet speed equivalent working effect of lock shaft torsion linkage.

[0039] see Image 6 , the double-bar buckle wheel 5B2 is composed of a frame ring chute frame 5B21, a double stacked wheel body 5B22, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com