Capture sieve and preparation method thereof

A capture and sieve technology, which is applied in the field of medical devices, can solve the problems of complex capture sieve structure and preparation process, low elution rate, and great impact on subsequent cell processing, and achieves controllable amount of thiol introduction and fast reaction process. , the effect of uniform reaction products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

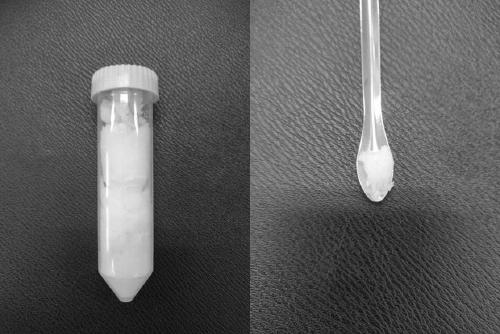

Image

Examples

Embodiment 1-1

[0055] Example 1-1 Preparation of thiolated sodium alginate

[0056] Step 1: Take 200mg of sodium alginate with a molecular weight of 34KDa and add it to a 250mL single-necked flask, add 120mL of MES buffer (pH=3), and stir to dissolve with a glass rod. Then add 17 mg of 3,3'-dithiobis(hydrazine propionate), and continue stirring until the system is uniform.

[0057] Step 2: Add 50 mg of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide to the single-necked flask, keep the pH of the system at 3, and continue the reaction for 12 hours.

[0058] Step 3: Add 0.5 g of tris(2-carbonylethyl)phosphorus hydrochloride into the single-necked flask, and react for 12 hours.

[0059] Step 4: Take out the solution in the single-necked flask, filter the reacted solution with a filter membrane with a pore size of 0.2 um, and inject the filtered solution into a dialysis bag with a pore size of 30 kDa.

[0060] Step 5: Add 200 mL of 10 mol / L HCl to 500 mL of purified water as a dialysate and add ...

Embodiment 1-2

[0062] Example 1-2 Preparation of thiolated sodium alginate

[0063] Step 1: Take 150mg of sodium alginate with a molecular weight of 20kDa and add it to a 250mL single-necked flask, add 100mL of MES buffer solution (pH=4.5), and stir to dissolve with a glass rod. Then add 16.5 mg of 3,3'-dithiobis(hydrazine propionate), and continue stirring until the system is uniform.

[0064] Step 2: Add 50 mg of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide into the single-necked flask, keep the pH of the system at 4.5, and continue the reaction for 5 hours.

[0065] Step 3: Add 0.05 g of tris(2-carbonylethyl)phosphorus hydrochloride into the single-necked flask, and react for 40 hours.

[0066] Step 4: Take out the solution in the single-necked flask, filter the reacted solution with a filter membrane with a pore size of 5 μm, and inject the filtered solution into a dialysis bag with a pore size of 20 kDa.

[0067] Step 5: Add 100 mL, 23 mol / L HCl into 1000 mL of purified water as a di...

Embodiment 1-3

[0069] Example 1-3 Preparation of thiolated sodium alginate

[0070] Step 1: Take 200mg of sodium alginate with a molecular weight of 34KDa and add it to a 250mL single-necked flask, add 120mL of MES buffer solution (pH=6), and stir to dissolve with a glass rod. Then add 30 mg of 3,3'-dithiobis(hydrazine propionate), and continue stirring until the system is uniform.

[0071] Step 2: Add 120 mg of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide into the single-necked flask, keep the pH of the system at 6, and continue the reaction for 5 hours.

[0072] Step 3: Add 0.5 g of tris(2-carbonylethyl)phosphorus hydrochloride into the single-necked flask, and react for 10 h.

[0073] Step 4: Take out the solution in the single-necked flask, filter the reacted solution with a filter membrane with a pore size of 0.2 um, and inject the filtered solution into a dialysis bag with a pore size of 30 kDa.

[0074] Step 5: Add 100 mL, 1 mol / L HCl into 1000 mL of purified water as a dialysate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com