laminated tube

A polyamide and semi-aromatic technology, applied in the field of laminated tubes, can solve the problems of insufficient barrier properties of chemical reagents, and achieve the effect of excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

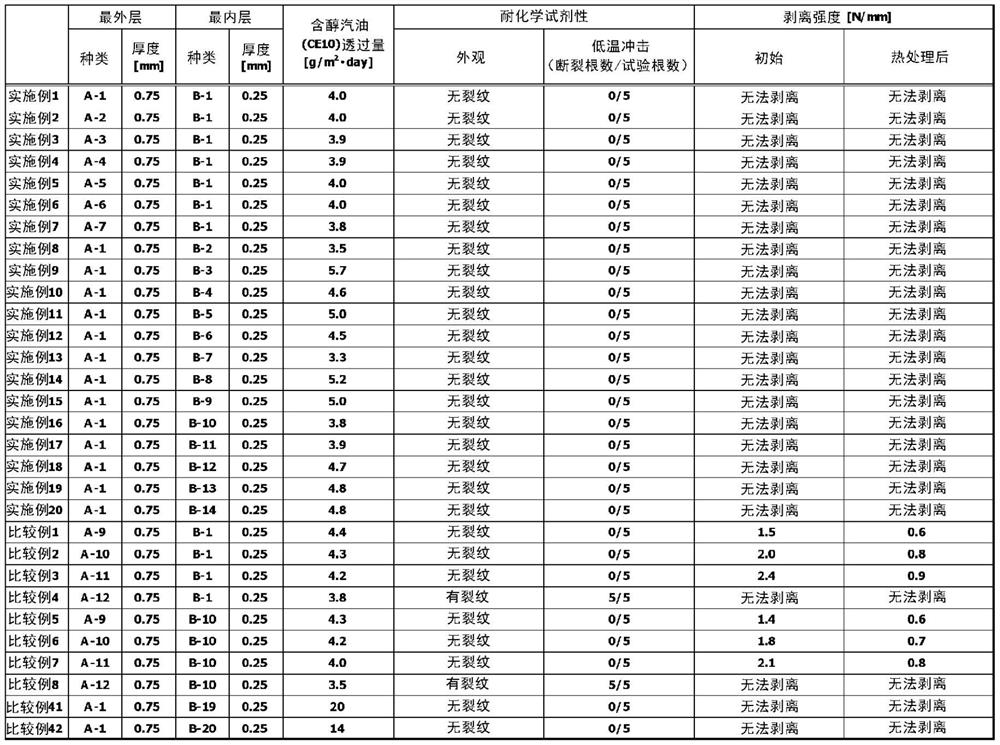

Embodiment 1

[0618] Using the polyamide 12 composition (A-1) and the semi-aromatic polyamide composition (B-1) shown above, using a Plabor (manufactured by Plastic Engineering Research Institute Co., Ltd.) two-layer pipe forming machine, the (A- 1) (B-1) was separately melted at an extrusion temperature of 270° C. and an extrusion temperature of 300° C., and the discharged molten resins were merged with a confluencer to form a laminated tubular body. Then, it is cooled and removed by a sizing die for controlling the size, and (a) layer (outermost layer) formed from (A-1) and (b) layer (outermost layer) formed from (B-1) are produced. Inner layer), a laminated tube having a layer structure of (a) / (b)=0.75 / 0.25 mm, an inner diameter of 6.0 mm, and an outer diameter of 8.0 mm was obtained. Table 1 shows the measurement results of physical properties of the laminated tube.

Embodiment 2

[0620] In Example 1, a laminated tube having a layer structure shown in Table 1 was obtained by the same method as in Example 1 except that the polyamide 12 composition (A-1) was changed to (A-2). Table 1 shows the measurement results of physical properties of the laminated tube.

Embodiment 3

[0622] In Example 1, a laminated tube having a layer structure shown in Table 1 was obtained by the same method as in Example 1 except that the polyamide 12 composition (A-1) was changed to (A-3). Table 1 shows the measurement results of physical properties of the laminated tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com