Single-phase composite metal oxide catalyst as well as preparation method and application thereof

A composite metal and oxide technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, carbon-based compound preparation, organic compound preparation, etc., can solve the problems of pollution and low atom utilization rate, and reduce the surface Effects of acidity, enhanced redox capacity, high feedstock conversion and product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

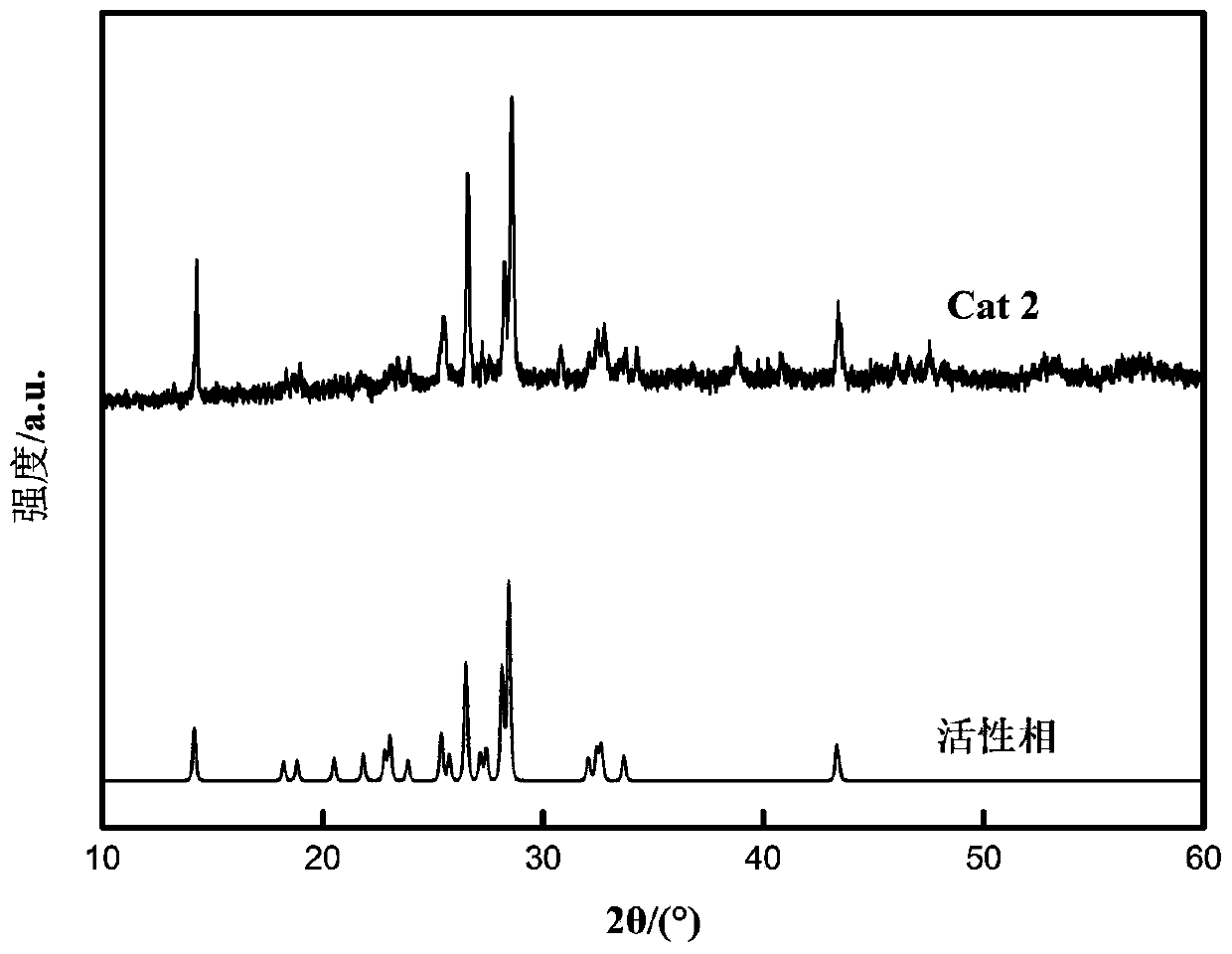

Image

Examples

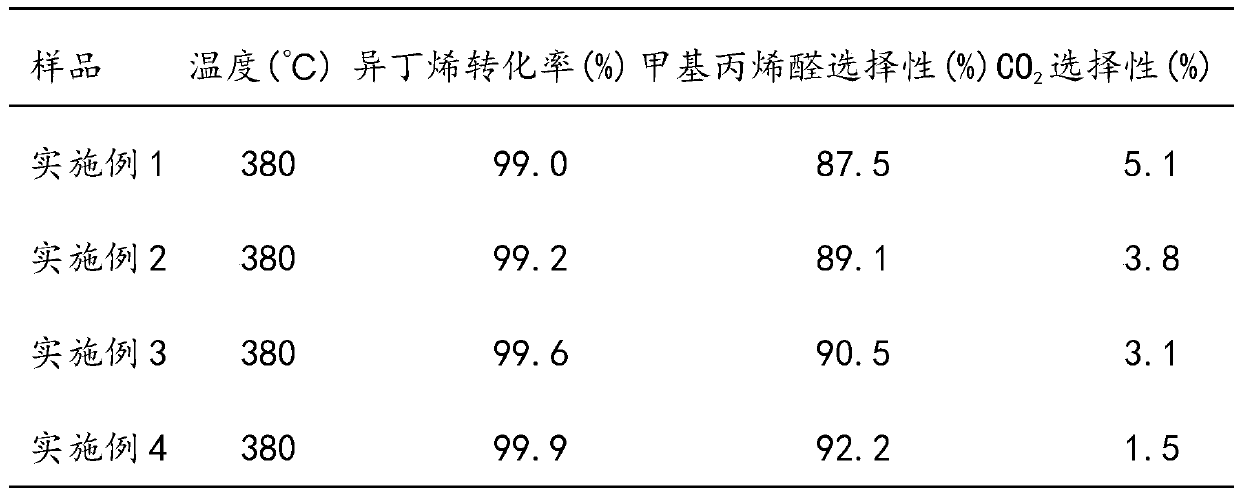

Embodiment 1

[0033] A preparation method of a single-phase composite metal oxide catalyst, the steps are as follows:

[0034] (1) Get 25g ammonium molybdate and dissolve in 160mL deionized water to obtain solution A;

[0035] (2) Get 13.78g cobalt nitrate and 9.3g bismuth nitrate and be dissolved in 20mL nitric acid solution, obtain solution B;

[0036] (3) Dissolve 14.75g of ferric nitrate in 20mL of deionized water to obtain solution C;

[0037] (4) Stir solution A at 60°C, add solution B and solution C to solution A dropwise, and continue stirring for 30 minutes to obtain a mixed solution;

[0038] (5) React the mixed solution in step (4) by hydrothermal method, put it into a reaction kettle, stir and age, the hydrothermal temperature is 120° C., react for 6 hours, and filter with suction;

[0039] (6) After aging, after drying in an oven at 120°C, pulverize and roast at 550°C to obtain a single-phase composite metal oxide catalyst, the molar ratio of Mo, Bi, Co, and Fe in the resulti...

Embodiment 2

[0041] A preparation method of a single-phase composite metal oxide catalyst, the steps are as follows:

[0042] (1) Get 25g ammonium molybdate and dissolve in 160mL deionized water to obtain solution A;

[0043] (2) Get 13.78g cobalt nitrate and 9.3g bismuth nitrate and be dissolved in 20mL nitric acid solution, obtain solution B;

[0044] (3) Dissolve 14.75g of ferric nitrate and 2.96g of manganese nitrate in 20mL of deionized water to obtain solution C;

[0045] (4) Stir solution A at 70°C, add solution B and solution C to solution A dropwise, and continue stirring for 20 minutes to obtain a mixed solution;

[0046] (5) React the mixed solution in step (4) by hydrothermal method, put it into a reaction kettle, stir and age, the hydrothermal temperature is 140° C., react for 4 hours, and filter with suction;

[0047] (6) After aging, after drying in an oven at 120°C, pulverize and roast at 520°C to obtain a single-phase composite metal oxide catalyst, the molar ratio of Mo...

Embodiment 3

[0049] A preparation method of a single-phase composite metal oxide catalyst, the steps are as follows:

[0050] (1) Get 25g ammonium molybdate and dissolve in 160mL deionized water to obtain solution A;

[0051] (2) Get 13.78g cobalt nitrate and 9.3g bismuth nitrate and be dissolved in 20mL nitric acid solution, obtain solution B;

[0052] (3) Dissolve 14.75g of ferric nitrate and 2.86g of copper nitrate in 20mL of deionized water to obtain solution C;

[0053] (4) Stir solution A at 55°C, add solution B and solution C to solution A dropwise, and continue stirring for 35 minutes to obtain a mixed solution;

[0054] (5) React the mixed solution in step (4) by hydrothermal method, put it into a reaction kettle, stir and age, the hydrothermal temperature is 160° C., react for 3 hours, and filter with suction;

[0055] (6) After aging, after drying in an oven at 140°C, pulverize and roast at 540°C to obtain a single-phase composite metal oxide catalyst, the molar ratio of Mo, B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com