Urea formaldehyde modified sodium alginate copolymer and application thereof

A technology of sodium alginate and copolymer, applied in application, water pollutants, fertilizer mixture and other directions, can solve the problems of high price of sodium alginate, poor chemical stability, etc., and achieve good slow-release effect, improved stability, and good biodegradation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

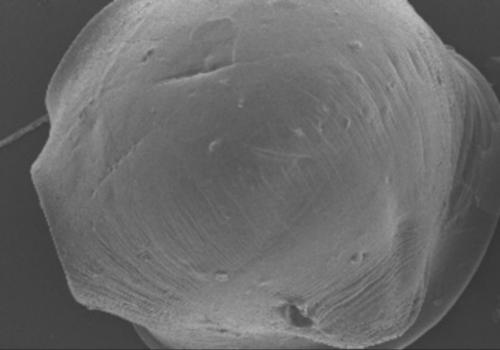

Image

Examples

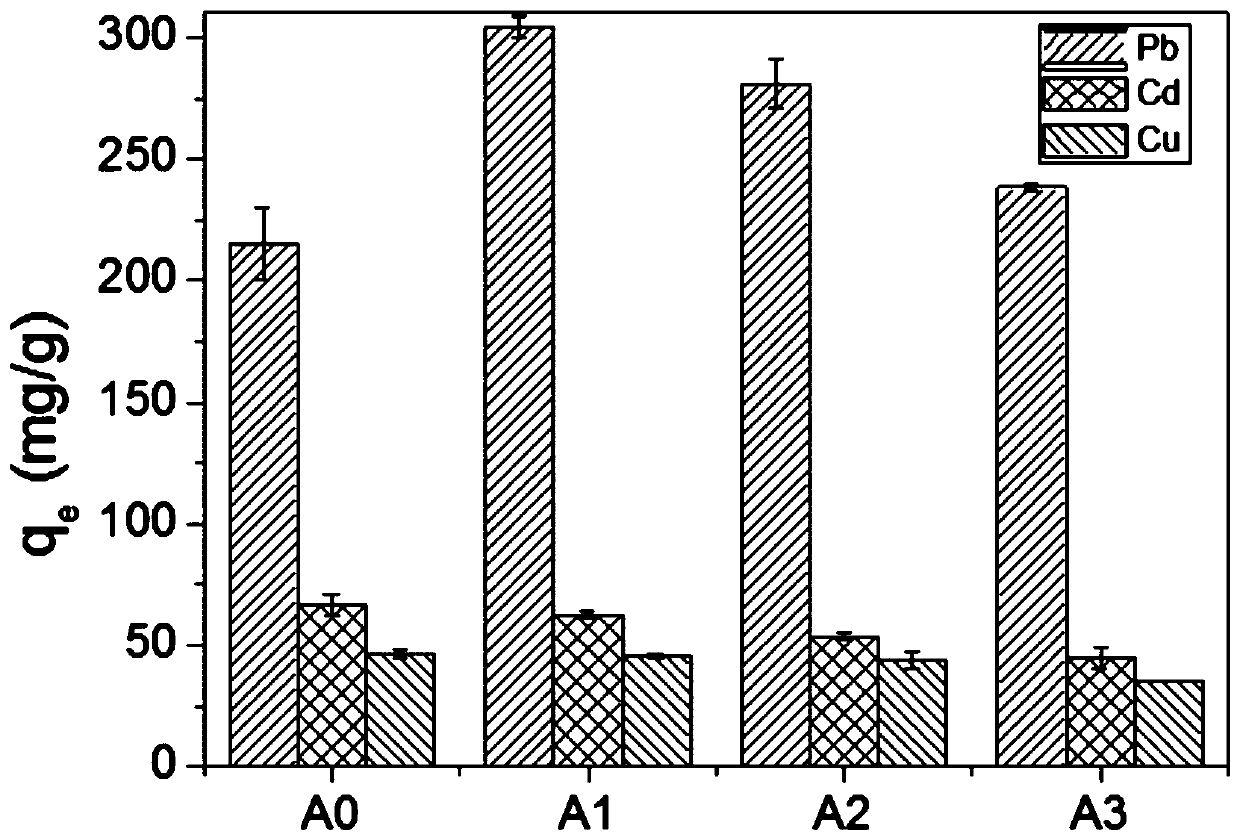

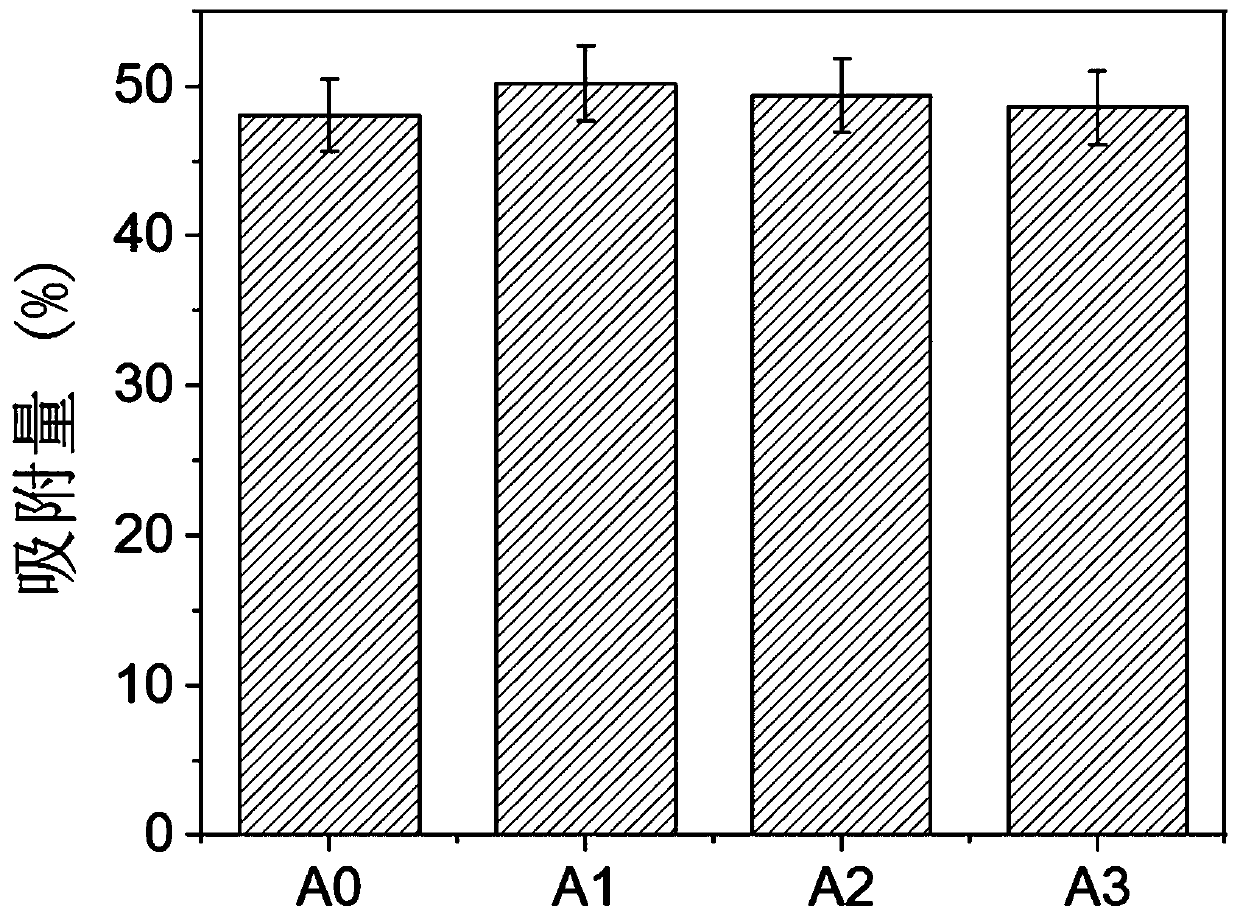

Embodiment 1

[0030] Preparation of copolymer A1, the specific preparation steps are as follows:

[0031] 1) Mix formaldehyde with the first batch of urea, adjust the pH to 7.5 with a 5% sodium hydroxide solution, and then raise the temperature to 60 o C, add the remaining urea, continue to heat up to 90 o C, insulation 30min, obtains hydroxymethyl urea;

[0032] In this embodiment, the molar ratio of formaldehyde to the total amount of urea added is 1.8:1, and the amount of the first batch of urea added is 40% of the total amount of urea;

[0033] 2) Add sodium alginate (powder) to the hydroxymethyl urea obtained in step 1), and adjust the pH to 5.0 with 5% ammonium chloride solution, 90 o After half an hour of C insulation reaction, the pH was adjusted to 7.5 with 5% sodium hydroxide by mass fraction, and after naturally cooling down to room temperature, a block copolymer was obtained; the mass ratio of sodium alginate and methylol urea added was 1 :5;

[0034] 3) Drop the block copol...

Embodiment 2

[0038] Prepare copolymer A2, its concrete steps are as follows:

[0039] 1) Mix formaldehyde and the first batch of urea in the reactor, adjust the pH to 7.5 with a 5% sodium hydroxide solution, and then raise the temperature to 60 oC, add the remaining urea, continue to heat up to 90 o C, insulation 30min, obtains hydroxymethyl urea;

[0040] In this embodiment, the molar ratio of formaldehyde to the total amount of urea added is 1.8:1, and the amount of the first batch of urea added is 50% of the total amount of urea;

[0041] 2) Add sodium alginate to the product after addition of urea and formaldehyde obtained in step 1), and adjust the pH to 5.0 with 5% ammonium chloride solution, 90 o After half an hour of C insulation reaction, adjust the pH to 7.5, and naturally cool down to room temperature to obtain a block copolymer; the mass ratio of sodium alginate and methylol urea added is 1:10;

[0042] 3) Drop the block copolymer mixture obtained in step 2) into a 0.1mol / L ...

Embodiment 3

[0044] To prepare copolymer A3, in this example, except that the mass ratio of sodium alginate to methylol urea is 1:15, other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com