Preparation method of CNTs/Ni composite material with high strength and high plasticity

A composite material and high plasticity technology, applied in electrolytic coatings, electrodes, coatings, etc., can solve problems such as poor dispersion of carbon nanotubes, and achieve the effect of improving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

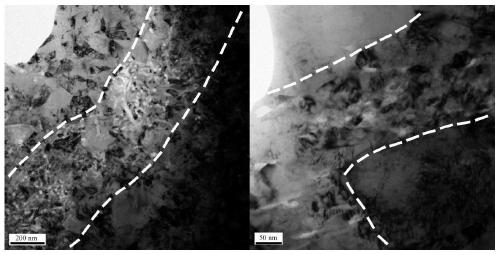

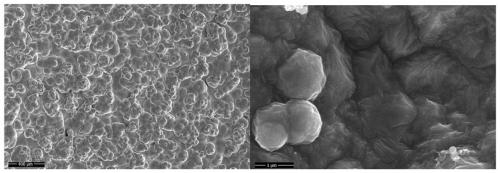

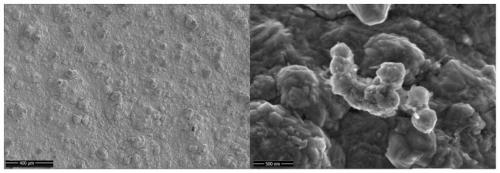

Image

Examples

Embodiment 1

[0025] (1) Carry out pretreatment to carbon nanotube: put the carbon nanotube of 5g / L in H 2 SO 4 and HNO 3 In the mixed solution (H 2 SO 4 and HNO 3 The volume ratio is 3:1), ultrasonically stirred for 20min, acidified in a water bath at 70°C for 5h, washed with distilled water until pH = 7, and then dried at 120°C.

[0026] (2) Perform pre-plating treatment on the stainless steel sheet with a thickness of 0.26mm: polish it with sandpaper until it is bright, and the order of the sandpaper used for grinding is 180#, 240#, 400#, 800#, 1200#, 2000#, rinse with water After that, place it in deionized water for ultrasonic cleaning for 15 minutes, pickle for 5 minutes (hydrochloric acid 5ml / L), connect the stainless steel sheet to the negative electrode of the power supply, and use a pure nickel plate (purity of 99.99wt%) as the anode. After polishing, cleaning and wrapping gauze Connect to the positive pole of the power supply.

[0027] (3) Prepare the plating solution: the ...

Embodiment 2

[0032] (1) Carry out pretreatment to carbon nanotube: put the carbon nanotube of 5g / L in H 2 SO 4 and HNO 3 In the mixed solution (H 2 SO 4 and HNO 3 The volume ratio is 3:1), ultrasonically stirred for 20min, acidified in a water bath at 70°C for 5h, washed with distilled water until pH = 7, and then dried at 120°C.

[0033] (2) Perform pre-plating treatment on the stainless steel sheet with a thickness of 0.26mm: polish it with sandpaper until it is bright, and the order of the sandpaper used for grinding is 180#, 240#, 400#, 800#, 1200#, 2000#, rinse with water After that, place it in deionized water for ultrasonic cleaning for 15 minutes, pickle for 5 minutes (hydrochloric acid 5ml / L), connect the stainless steel sheet to the negative electrode of the power supply, and use a pure nickel plate (purity of 99.99wt%) as the anode. After polishing, cleaning and wrapping gauze Connect to the positive pole of the power supply.

[0034] (3) Prepare the plating solution: the ...

Embodiment 3

[0039] (1) Carry out pretreatment to carbon nanotube: put the carbon nanotube of 5g / L in H 2 SO 4 and HNO 3 In the mixed solution (H 2 SO 4 and HNO 3 The volume ratio is 3:1), ultrasonically stirred for 20min, acidified in a water bath at 70°C for 5h, washed with distilled water until pH = 7, and then dried at 120°C.

[0040] (2) Perform pre-plating treatment on the stainless steel sheet with a thickness of 0.26mm: polish it with sandpaper until it is bright, and the order of the sandpaper used for grinding is 180#, 240#, 400#, 800#, 1200#, 2000#, rinse with water After that, place it in deionized water for ultrasonic cleaning for 15 minutes, pickle for 5 minutes (hydrochloric acid 5ml / L), connect the stainless steel sheet to the negative electrode of the power supply, and use a pure nickel plate (purity of 99.99wt%) as the anode. After polishing, cleaning and wrapping gauze Connect to the positive pole of the power supply.

[0041] (3) Prepare the plating solution: the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com