A pressure detection device and system

A detection device and pressure technology, applied in the field of measurement, can solve the problems of difficult disassembly, charging, maintenance and replacement of the detection device, limited measurement distance and working time, errors in ultrasonic echo measurement methods, etc., so as to improve reliability and service life. Simple structure, the effect of reducing structure and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

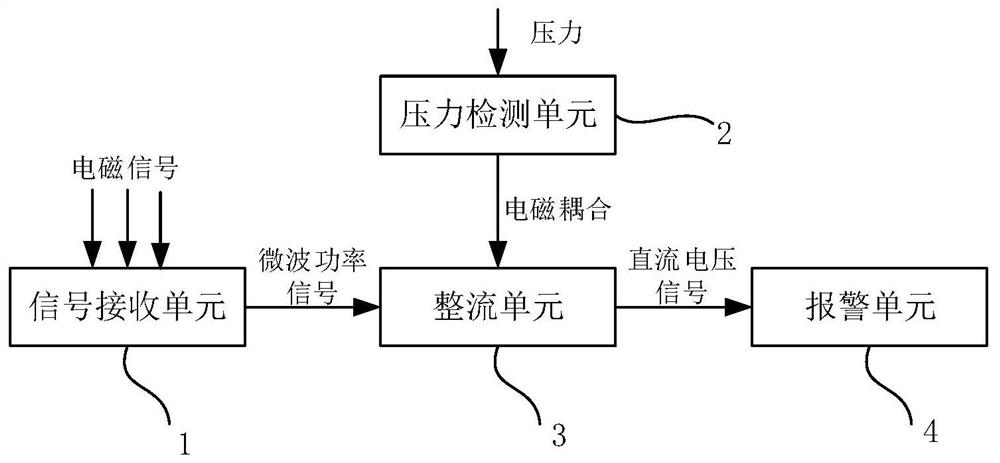

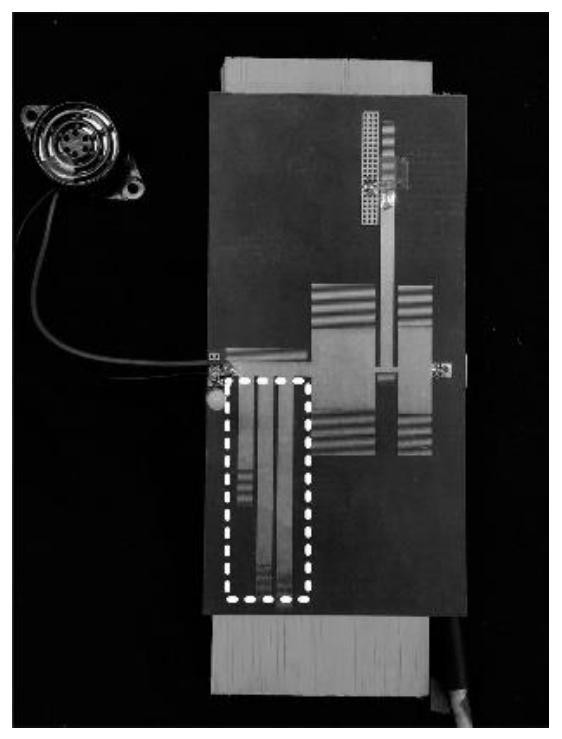

[0039] See figure 1 , figure 1 It is a schematic diagram of a pressure detection device provided by an embodiment of the present invention, including:

[0040] A signal receiving unit 1, configured to receive an electromagnetic signal, and convert the electromagnetic signal into a microwave power signal with a standard impedance;

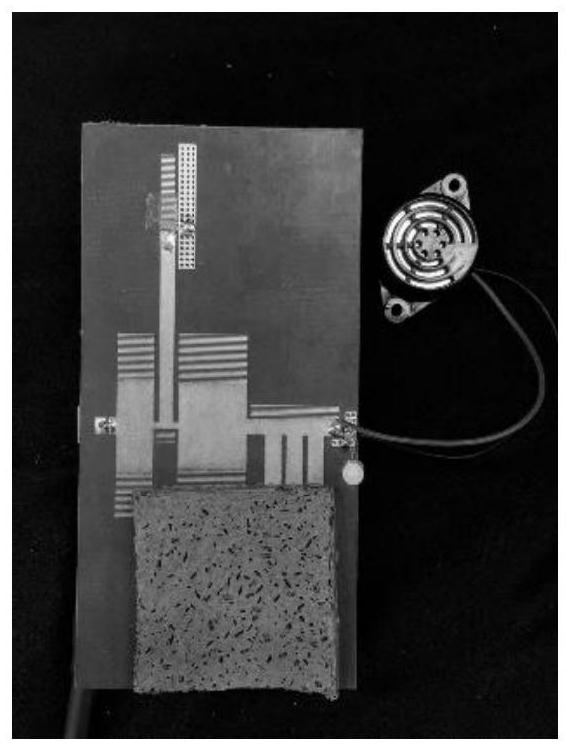

[0041] A pressure detection unit 2, which has a pressure sensitive element, so that when the pressure detection unit 2 is subjected to the pressure applied by the object to be detected, the dielectric constant of the pressure sensitive element is changed;

[0042] The rectification unit 3 is connected to the pressure detection unit 1 through electromagnetic coupling, and is electrically connected to the signal receiving unit, and is used to rectify the microwave power signal and output a DC voltage signal, and the dielectric constant of the pressure sensitive element adjusting said DC voltage signal when a change occurs;

[0043] The alarm unit 4...

Embodiment 2

[0068] This embodiment provides a pressure detection system for detecting the pressure inside a building. See Figure 5 , Figure 5 It is a structural schematic diagram of a pressure detection system provided by an example of the present invention, including: a transmitting end A and a receiving end B, wherein,

[0069] The transmitting terminal A is used to transmit electromagnetic signals; it includes a signal source, an amplifier and a transmitting antenna;

[0070] The receiving terminal B is wirelessly connected to the transmitting terminal A, and is used to receive the electromagnetic signal and convert it into microwave power with standard impedance, and then rectify it into DC power, so as to output a voltage signal, which includes as in the first embodiment The pressure detection device.

[0071] Considering that the pressure detection system provided in this embodiment is used to detect the internal pressure of the building, the alarm device and the receiving end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com