Test strip for detecting creatinine by electrochemical method and preparation method thereof

An electrochemical and test strip technology, applied in the detection field, can solve the problems of high price, complicated operation, inconvenience for users or patients, etc., and achieve the effect of simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

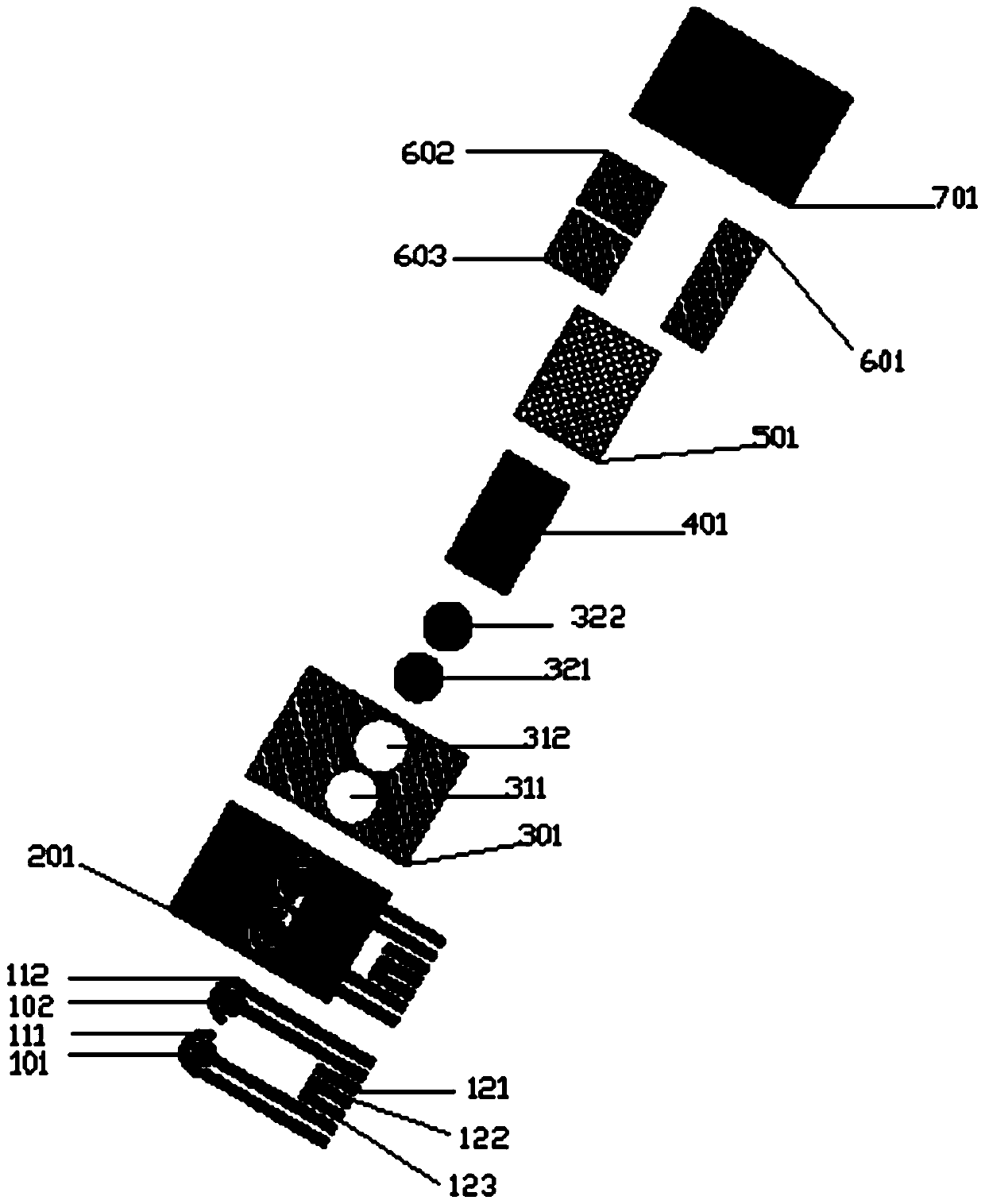

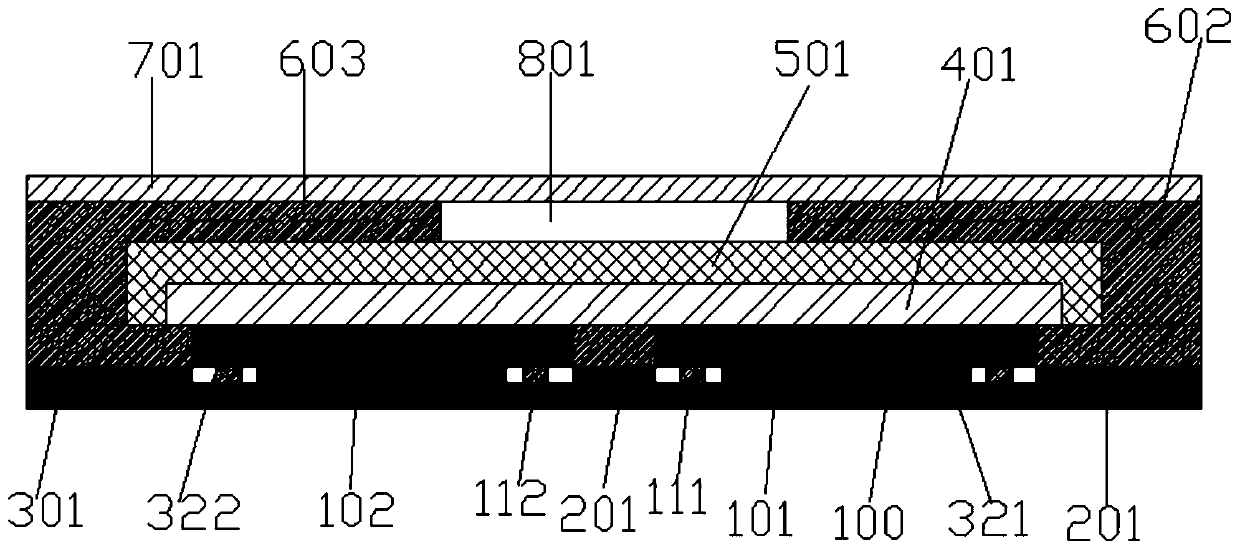

[0048] A preparation method of a test strip for electrochemical detection of creatinine, comprising the steps of:

[0049] Step 1: Prepare the first reaction solution according to the following formula, the formula includes: 5-100KU / L creatinase, 5-200KU / L sarcosine oxidase, 5-200KU / L creatine hydrolase, 1-100KU / L ascorbic acid Oxidase, 1-100KU / L peroxidase, 10-200g / L dispersant, 0.1-10g / L surfactant, 0.05-1M buffer; stir for one hour before use;

[0050] Step 2: Prepare the second reaction solution according to the following formula, the formula includes: 5-200KU / L sarcosine oxidase, 5-200KU / L creatine hydrolase, 1-100KU / L ascorbate oxidase, 1-100KU / L Peroxidase, 10-200g / L stabilizer, 0.1-10g / L surfactant, 0.05-1M buffer; stir for one hour before use;

[0051] Step 3: preparing the first enzyme carrier layer 321,

[0052] Soak the enzyme carrier layer in the first reaction solution for 1-10 minutes, take it out, and dry it for 10-60 minutes at 25-50 degrees to obtain the fi...

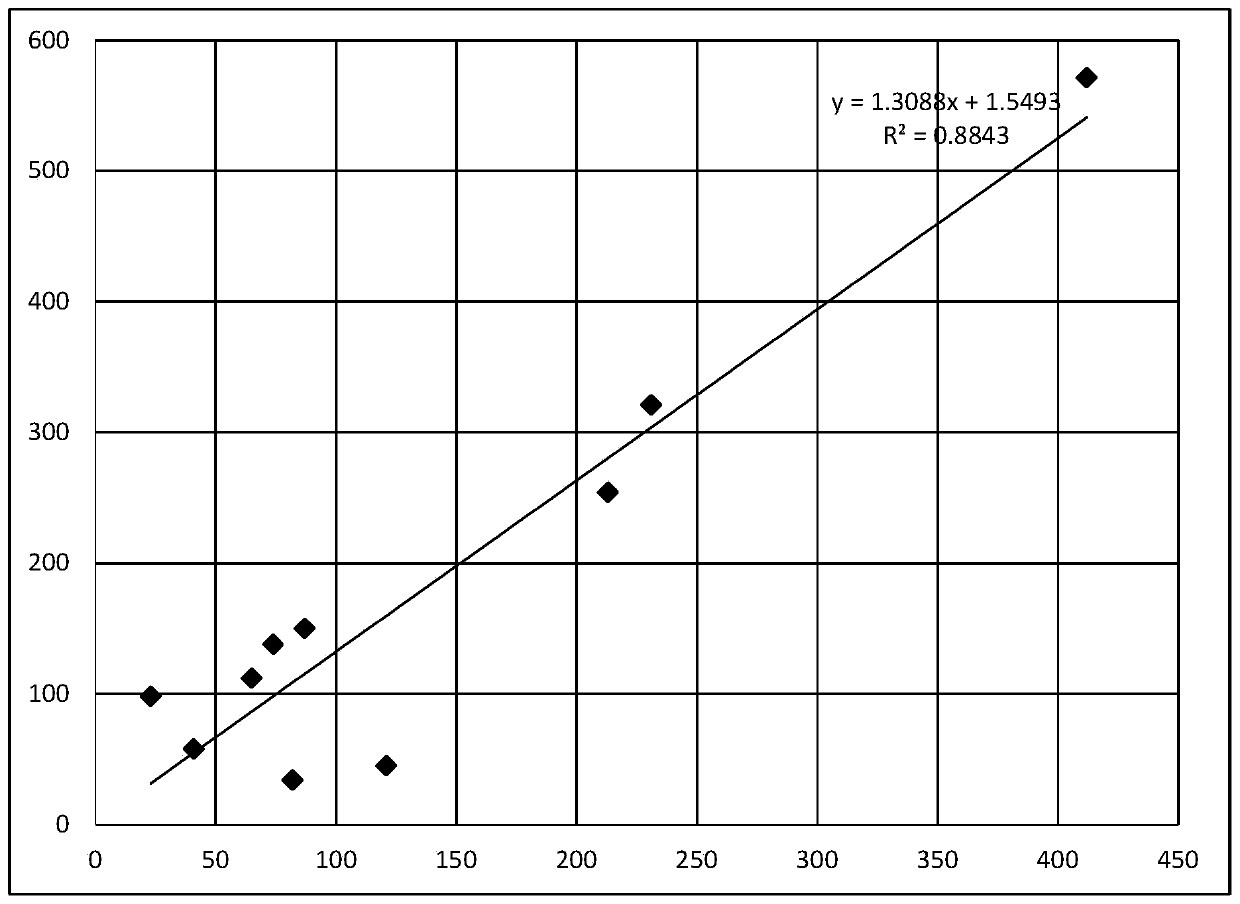

Embodiment 1

[0061] The preparation method of finished product 1 comprises the following steps:

[0062] Step 1: Prepare the first reaction solution according to the following formula, which includes: 50KU / L creatinase, 100KU / L sarcosine oxidase, 100KU / L creatine hydrolase, 20KU / L ascorbate oxidase, 50KU / L peroxidase Phosphate buffer, 20g / L polyvinylpyrrolidone, 0.1g / L Emulgen B66, 0.05MPH=6 phosphate buffer; stir for one hour before use;

[0063] Step 2: Enzyme carrier layer 321: soak the enzyme carrier layer in the reaction solution for 5 minutes, take it out, and dry it at 45 degrees for 20 minutes before use;

[0064] Step 3: Preparation of working carbon slurry: Add the electron mediator ferrocenemethanol into the carbon slurry CH-10, stir well and set aside

[0065] Step 4: Take the substrate 100, first print the counter electrodes 111 and 112, then take the above-prepared working carbon paste and print the working electrodes 101 and 102, then print the insulating layer 201, and dry...

Embodiment 2

[0073] The preparation method of finished product 2 comprises the following steps:

[0074] Step 1: Prepare the first reaction solution according to the following formula, which includes: 50KU / L creatinase, 100KU / L sarcosine oxidase, 100KU / L creatine hydrolase, 20KU / L ascorbate oxidase, 50KU / L peroxidase Phosphate buffer, 20g / L polyvinylpyrrolidone, 0.1g / L Emulgen B66, 0.05MPH=6 phosphate buffer; stir for one hour before use;

[0075] Step 2: Prepare the second reaction solution according to the following formula, the formula includes: 100KU / L sarcosine oxidase, 100KU / L creatine hydrolase, 20KU / L ascorbate oxidase, 50KU / L peroxidase, 20g / L Polyvinylpyrrolidone, 0.1g / LEmulgen B66, 0.05MPH=6 phosphate buffer; stir for one hour before use;

[0076] Step 3: the first enzyme carrier layer 321: soak the enzyme carrier layer in the first reaction solution for 5 minutes, take it out, dry it at 45 degrees for 20 minutes, and set it aside;

[0077] Step 4: the second enzyme carrier la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com