Pressurized water reactor nuclear power plant first circulation starting primary loop deoxidization method based on acid condition

An acid condition, pressurized water reactor technology, applied in nuclear power plants, nuclear power generation, detailed information of nuclear power plants, etc., can solve problems such as restricting the speed of chemical deoxygenation, affecting the critical path of unit startup, etc., to reduce the critical path of deoxygenation, improve Chemical deoxidizing effect, effect of low initial oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

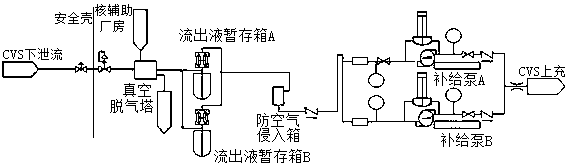

[0057] A method for deoxygenating the first cycle of a pressurized water reactor nuclear power plant based on acidic conditions, including

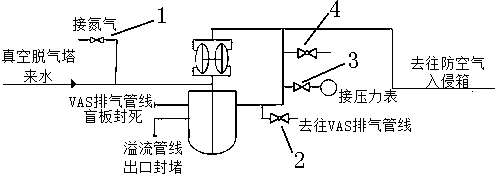

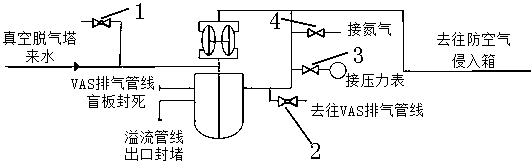

[0058] The L1 effluent temporary storage tank is purged with nitrogen. Such as figure 2As shown, it specifically includes 11. Blocking the overflow ports of the effluent temporary storage tanks A and B. 12. Install blind plates at the joint flanges of the effluent temporary storage tanks A, B and the VAS exhaust pipeline. During the process of charging and discharging, the effluent temporary storage tanks A and B will absorb oxygen in the air, resulting in an increase in dissolved oxygen, which cannot achieve the purpose of oxygen removal. Therefore, it is necessary to maintain the effluent temporary storage tanks without affecting the equipment function seal on. 13. Install the inlet pipeline exhaust valve 3 on the effluent temporary storage tanks A and B, and install a temporary pressure gauge on the inlet pipeline exhaust valve 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com