Energy-saving cement and preparation method thereof

An energy-saving, cement-based technology, applied in the direction of cement production, etc., can solve problems such as consumption, high sintering temperature, and more energy, and achieve the effect of reducing the amount, reducing the sintering temperature, and improving the degree of reaction adequacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

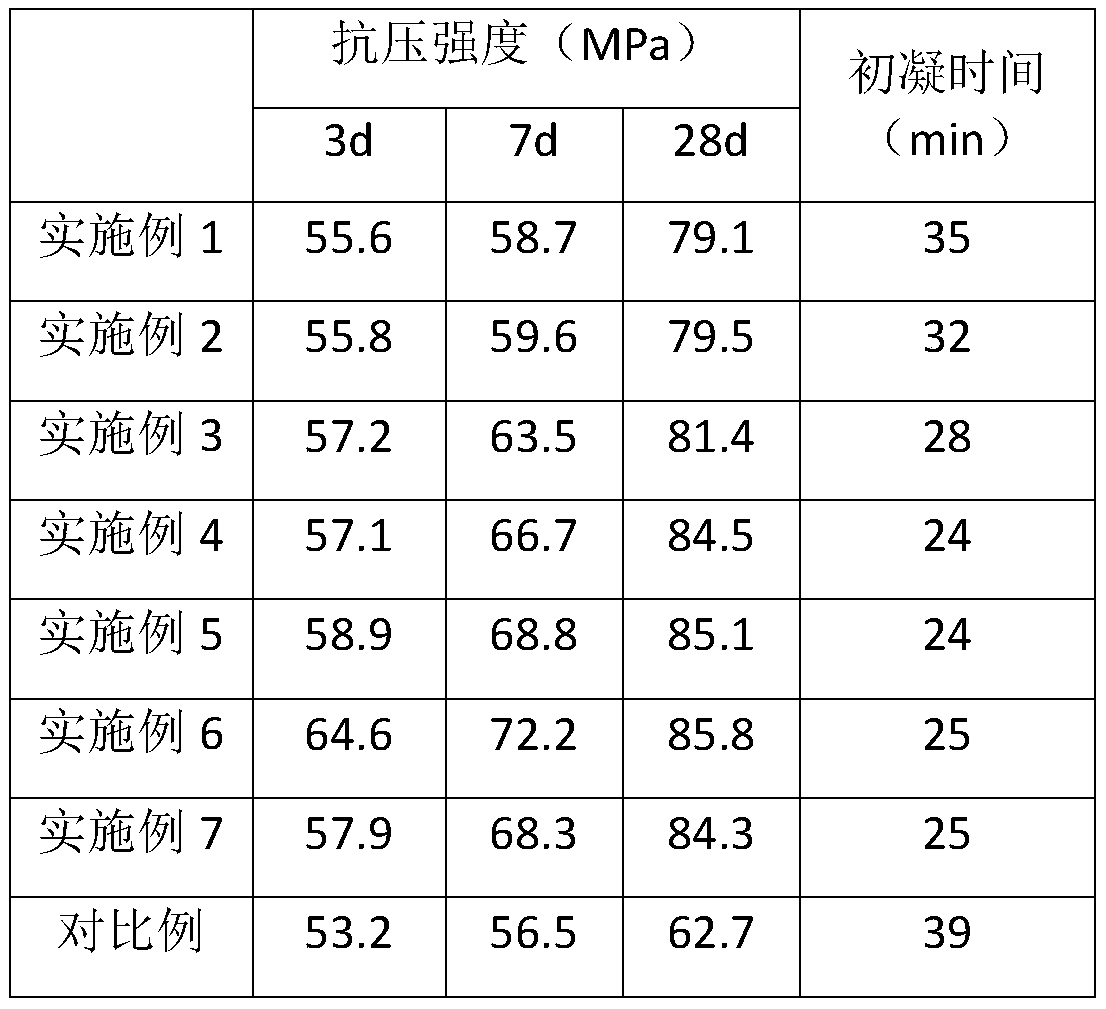

Examples

Embodiment 1

[0044] The energy-saving cement in this embodiment is made by mixing cement clinker and admixture according to the weight ratio of 93:7. The cement clinker is made from the following raw materials: 42.3t of power plant fly ash, 8.3t of bauxite, and 84.5t of limestone. t, gypsum 0.4t, iron ore 1.6t. The mixed material is composed of limestone powder, Class II fly ash, gypsum powder and converter slag powder in a weight ratio of 10.6:16.8:11.7:7.5. Wherein, power plant fly ash comprises the composition of following percentage by weight: 46.67% SiO 2 , 27.31% Al 2 o 3 , 5.89% Fe 2 o 3 , 3.27% CaO, 4.45% SO 3 , 0.8% MgO, 1.03% K 2 O. Al in bauxite 2 o 3 The weight percentage is 71.7%. Fe in iron ore 2 o 3 The calculated weight percentage is 39.23%. Converter slag includes the following components by weight: 48.32% CaO, 14.28% SiO 2 , 2.88% Al 2 o 3 , 8.99% Fe 2 o 3 , 8.79% MgO, 0.56% P 2 o 5 , 0.87% f-CaO.

[0045] The preparation technology of the energy-savi...

Embodiment 2

[0050] The energy-saving cement in this embodiment is made by mixing cement clinker and admixture according to the weight ratio of 88:12. The cement clinker is made from the following raw materials: 44.1t of power plant fly ash, 8.8t of bauxite, and 86.2t of limestone. t, gypsum 0.6t, iron ore 1.8t, clay 3.5t, metakaolin 12.5t. The mixed material is composed of limestone powder, Class II fly ash, gypsum powder and converter slag powder in a weight ratio of 10.6:16.8:11.7:7.5. Wherein, power plant fly ash comprises the composition of following percentage by weight: 46.67% SiO 2 , 27.31% Al 2 o 3 , 5.89% Fe 2 o 3 , 3.27% CaO, 4.45% SO 3 , 0.8% MgO, 1-1.3K 2 O. Al in bauxite 2 o 3 The weight percentage is 71.7%. Fe in iron ore 2 o 3 The calculated weight percentage is 39.23%. Converter slag includes the following components by weight: 48.32% CaO, 14.28% SiO 2 , 2.88% Al 2 o 3 , 8.99% Fe 2 o 3 , 8.79% MgO, 0.56% P 2 o 5 , 0.87% f-CaO. Al in clay 2 o 3 The we...

Embodiment 3

[0056] The energy-saving cement in this embodiment is made by mixing cement clinker and admixture according to the weight ratio of 85:15. The cement clinker is made from the following raw materials: 43.5t of power plant fly ash, 9.2t of bauxite, and 91.7t of limestone. t, gypsum 0.8t, iron ore 2.2t, clay 4.5t, metakaolin 11.0t, zinc oxide 2.8t, fluorite 0.5t, barium slag 1.2t. The mixed material is composed of limestone powder, Class II fly ash, gypsum powder and converter slag powder in a weight ratio of 10.6:16.8:11.7:7.5. Wherein, power plant fly ash comprises the composition of following percentage by weight: 46.67% SiO 2 , 27.31% Al 2 o 3 , 5.89% Fe 2 o 3 , 3.27% CaO, 4.45% SO 3 , 0.8% MgO, 1-1.3K 2 O. Al in bauxite 2 o 3 The weight percentage is 71.7%. Fe in iron ore 2 o 3 The calculated weight percentage is 39.23%. Converter slag includes the following components by weight: 48.32% CaO, 14.28% SiO 2 , 2.88% Al 2 o 3 , 8.99% Fe 2 o 3 , 8.79% MgO, 0.56% P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com