Van der Waals' force oil saving agent and preparation method thereof

A technology of fuel-saving agent and fuel-saving agent, which is applied in the field of van der Waals fuel-saving agent and its preparation, can solve the problems of rising exhaust resistance, large exhaust resistance, power decline, etc., achieve stable idle speed, reduce exhaust emissions, speed up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A van der Waals oil-saving agent, characterized in that it includes the following raw materials: 20wt% iron, 25wt% silicon, 30wt% aluminum, 5wt% calcium, 10wt% cobalt, 0.3wt% cerium, 0.3wt% lanthanum, and 0.1wt% platinum %, Neodymium 0.2wt% and Palladium 0.1wt%.

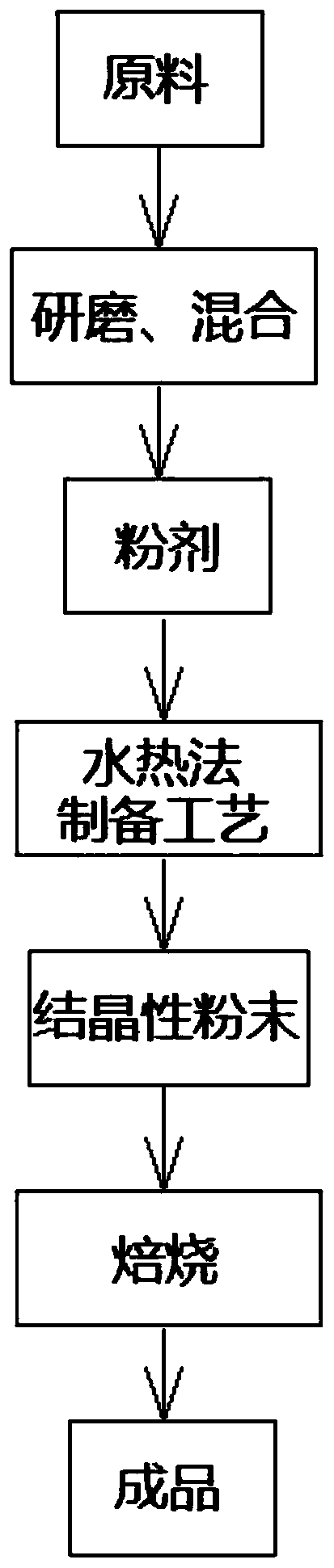

[0019] see figure 1 , a preparation method of a van der Waals oil-saving agent, specifically comprising the following steps:

[0020] (1) Grinding and mixing the raw materials of the van der Waals fuel-saving agent to obtain a powder;

[0021] (2) Put the above-mentioned powder in a sealed reaction container, use water as the reaction medium, and prepare a crystalline powder by hydrothermal method under the temperature condition of 300°C and the pressure condition of 6MPa, which is the van der Waals force Semi-finished products of fuel-saving agent;

[0022] In this step, the crystal structure, crystal form and grain purity of the crystalline powder can be controlled by adjusting the reaction conditions. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com