Lithium metal interface modification method for room-temperature solid-state battery

A solid-state battery and interface modification technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., to achieve the effect of reducing interface impedance, reducing interface impedance, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for modifying the lithium metal interface of a room temperature solid-state battery, which specifically includes the following steps:

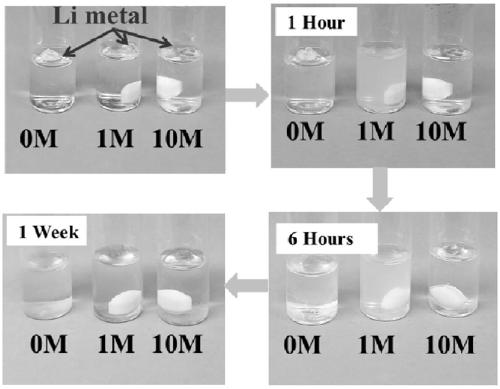

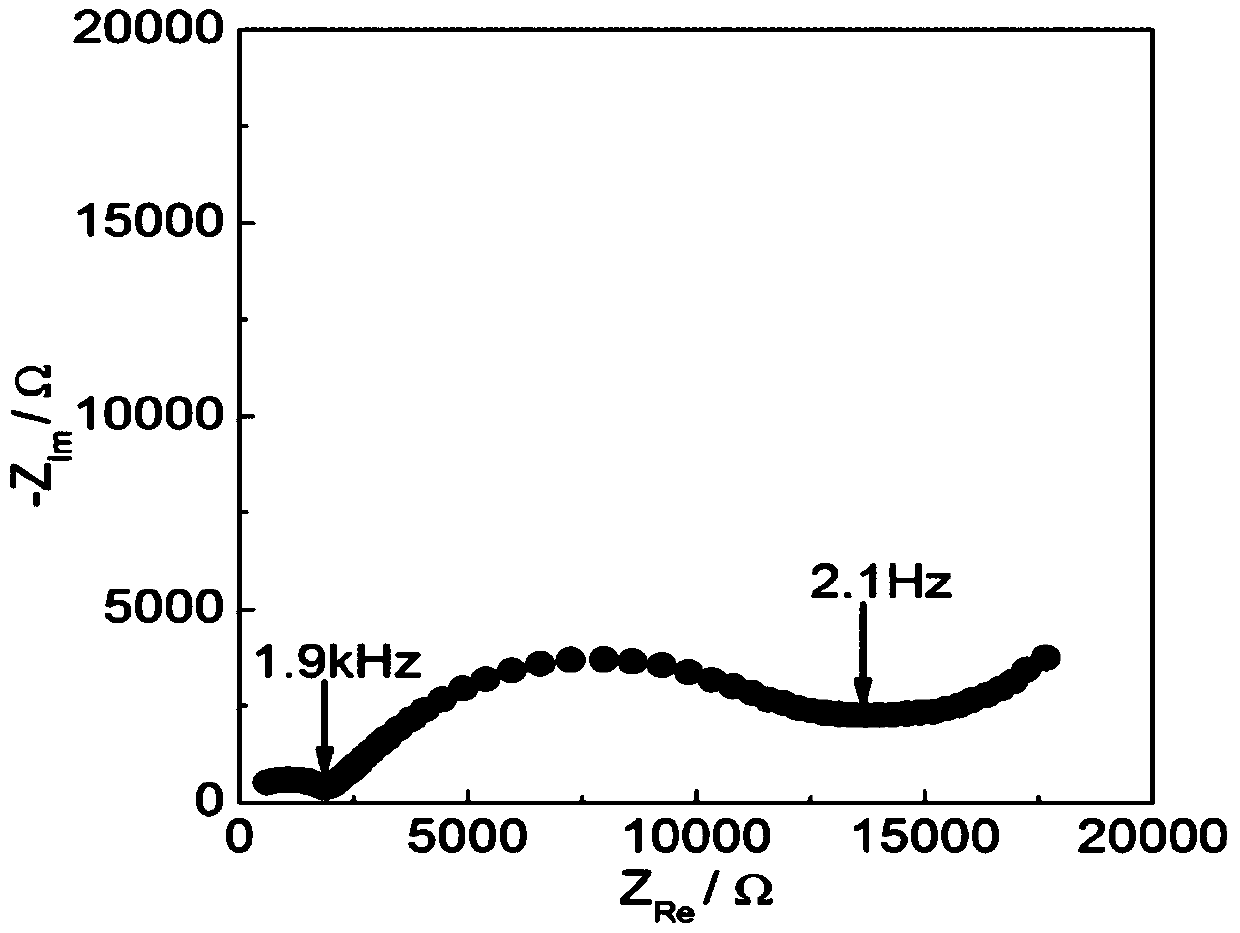

[0033] PEO:LiClO 4 : LLZTO (the molecular weight of PEO is: 10000) is added 9mL of acetonitrile solution according to the weight ratio of 0.4:0.2:0.6, stirred at 500rpm in argon atmosphere to make it uniformly dispersed, according to figure 1 Assemble the battery, add 5uL of 10mol L between the negative electrode and the composite electrolyte -1 Lithium metal modified with LITFSI / AN solution and dried at 40°C. Its electrochemical performance was tested at 30 °C.

[0034] figure 1 A schematic diagram of a solid-state battery (button battery), using lithium iron phosphate (LFP) as the positive electrode, using a very small amount (5 μL) of 10M LiTFSI:AN to wet the surface of lithium metal, and then using the modified lithium metal as the negative electrode of the solid-state battery, assemble Into LFP...

Embodiment 2

[0039] This embodiment provides a method for modifying the lithium metal interface of a room temperature solid-state battery, which specifically includes the following steps:

[0040] Add 9 mL of chloroform solution to PEO:LiTFSI:LLZTO (the molecular weight of PEO is: 50000) according to the weight ratio of 0.4:0.3:0.6, and stir at 300 rpm in a hydrogen-argon atmosphere to make it uniformly dispersed. figure 1 Assemble the battery, add 15uL of 12mol L between the negative electrode and the composite electrolyte -1 Lithium metal modified with LITFSI / AN solution and dried at 50°C. Its electrochemical performance was tested at 30 °C.

Embodiment 3

[0042] This embodiment provides a method for modifying the lithium metal interface of a room temperature solid-state battery, which specifically includes the following steps:

[0043] PEO:LiTPF 6 : LLZTO (the molecular weight of PEO is: 100000) is added 9mL of dichloroethane solution according to the weight ratio of 0.4:0.25:0.6, and the helium atmosphere is ultrasonically dispersed to make it uniformly dispersed. figure 1 Assemble the battery, add 7.5uL of 12mol L between the negative electrode and the composite electrolyte -1 Lithium metal modified with LITFSI / AN solution and dried at 60°C. Its electrochemical performance was tested at 30 °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com